냉동 고기 슬라이서 기계

| 모델 | TZ-MR-2 |

| 전력 | 2200w |

| 크기 | 1200*560*1200mm |

| 무게 | 200kg |

| 용량 | 50-300kg/h |

| 전압 | 220v |

이제 저희 프로젝트 관리자에게 기술 세부 정보를 요청할 수 있습니다

이 냉동 육절단기는 냉동 소고기, 양고기, 돼지고기 및 기타 육류를 해동할 필요 없이 균일한 슬라이스 또는 롤로 절단할 수 있습니다.

시간당 50 kg에서 1200 kg의 처리 능력을 갖추어 높은 효율과 일관된 결과를 보장하며 식당, 훠궈점, 정육점 및 대규모 육류 가공 공장에 이상적입니다.

판매 중인 냉동 육류 슬라이서 기계

일반적으로 미트 슬라이서, 양 슬라이서 또는 소고기 절단기로 불리며 해동이 필요 없고 정밀 절단과 균일한 결과를 보장합니다.

이 기계는 정밀 절단을 위한 CNC 슬라이서, 공간 절약형 수직 및 데스크탑 슬라이서, 2롤, 4롤 또는 8롤 구성으로 제공되는 다중 롤 슬라이서 등 다양한 모델로 제공되어 다양한 생산 요구를 충족합니다.

냉동 고기 슬라이서 기계의 특징

- 해동이 필요 없음 – 냉동 소고기, 양고기, 돼지고기 및 기타 육류를 직접 슬라이스하여 시간 절약과 신선도 유지.

- 조절 가능한 두께 – 슬라이싱 두께를 쉽게 조절하여 다양한 조리 또는 가공 요구에 부응.

- 고용량 범위 – 지지대 시간당 50–1200kg, 소규모 상점과 대형 육류 가공 공장 모두에 적합합니다.

- 균일한 슬라이싱 – 육류 슬라이스 또는 롤의 크기와 모양을 일관되게 유지하여 훠궈 레스토랑 및 포장 육류 제품에 이상적입니다.

- 내구성이 뛰어난 스테인리스 강 본체 – 식품 등급 구조, 녹 방지, 세척이 용이하여 장기 사용 가능.

- 사용자 친화적인 조작 – 높은 안전 기준을 갖춘 간단한 제어 시스템으로 노동 강도를 줄이고 효율성을 향상시킵니다.

- 넓은 응용 분야 – 레스토랑, 정육점, 슈퍼마켓, 냉동 육류 가공 공장에서 널리 사용됩니다.

냉동 육류 롤링 기계의 구조

- 스테인리스 강 프레임 및 베이스 – 모든 부품을 수용하는 견고한 구조.

- 슬라이싱 챔버 – 냉동 육류를 안전하게 고정하여 정밀한 슬라이싱과 롤링 가능.

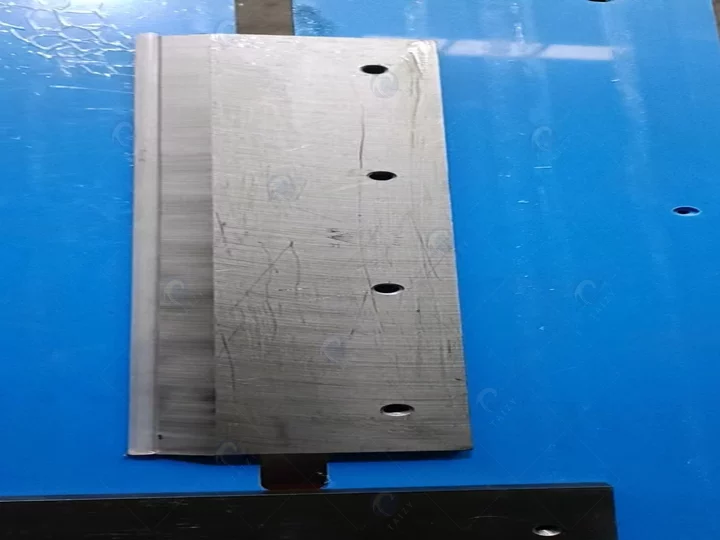

- 블레이드 어셈블리 – 날카로운 스테인리스 강 블레이드로 냉동 육류를 손쉽게 절단.

- 두께 조절 – 다양한 요구에 맞춘 슬라이스 두께 조절 가능.

- 강력한 모터 – 원활하고 효율적인 슬라이싱 성능을 보장합니다.

- 안전 시스템 – 비상 정지, 인터록, 보호 커버.

- 제어 패널 – 슬라이싱 매개변수의 손쉬운 설정 및 모니터링.

- 조절 가능한 다리/바퀴 – 안정적인 배치와 편리한 이동성.

냉동 고기 슬라이서 기계는 어떻게 작동하나요?

- 이 기계는 이중 가이드 급여 시스템을 사용하여 절단 두께를 조절하면서 냉동 육류를 자동으로 밀고 압착하여 일관된 절단을 제공합니다.

- 절단이 완료되면 칼날이 자동으로 정지하고 미트 푸셔가 안전하게 후퇴합니다.

- 커터와 컨베이어 벨트는 동기화되어 작동하며 보호 도어를 열면 즉시 전원이 차단되어 작업자 안전을 보장합니다.

냉동 고기 슬라이서 기계를 사용하는 방법은?

- 준비 및 적재. 적절한 크기의 냉동 고기를 급지 트레이에 놓습니다.

- 두께 설정. 제어판을 사용하여 슬라이스 두께를 조정합니다.

- 슬라이스를 시작하세요. 자동 슬라이스를 시작하려면 기계를 켜세요.

- 슬라이스를 수집하세요. 요리나 추가 가공을 위해 슬라이스된 고기를 모으세요.

- 기계를 청소하세요. 사용 후 기계를 청소하고 소독하여 위생을 유지하고 서비스 수명을 연장하세요.

냉동 고기 슬라이서 기계 사용 팁

- 고기가 제대로 얼어있지만 지나치게 단단하지 않은지 확인하세요 - 일반적으로 -6°C 이상의 온도에서. 너무 단단하면 슬라이스하기 전에 약간 해동하세요.

- 날이 손상되지 않도록 항상 고기에서 뼈를 제거하세요.

- 선호하는 슬라이스 두께를 설정하기 전에 고기를 기계에 넣으세요.

- 날이 제대로 잡히지 않거나 고르지 않게 자르면, 칼날이 무르거나 녹슬었을 수 있으며 최적의 성능을 위해 날을 갈아야 합니다.

냉동 육류 슬라이서의 기술 매개변수

| 모델 | 전압 | 용량 | 전력 | 무게 | 크기 | 슬라이스 길이 | 슬라이스 너비 |

| TZ-MR-2 | 220v | 50-300kg/h | 2200w | 200kg | 1200*560*1200mm | 600mm | 270mm |

| TZ-MR-4 | 380v | 50-600kg/h | 3000w | 320kg | 1200*800*1200mm | 600mm | 510mm |

| TZ-MR-6 | 380v | 50-900kg/h | 3000w | 400kg | 1200*1010*1200mm | 600mm | 730mm |

| TZ-MR-8 | 380v | 50-1200kg/h | 4000w | 500kg | 1200*1320*1200mm | 600mm | 920mm |

두 롤 냉동 고기 슬라이서 기계

여덟 롤 냉동 슬라이서 기계

문의하기

냉동 육절단기 외에도 당사는 다양한 육류 가공 기계를 제공하여 다양한 생산 요구를 충족합니다.

자세한 내용 및 견적은 언제든지 문의해 주세요—귀사에 적합한 솔루션을 찾을 수 있도록 도와드리겠습니다!