Injera Making Machine | Ethiopia Injera Machine

| Model | TZ-3620 |

| Size | 1800*660*890mm |

| Weight | 260kg |

| Capacity | 800-1000pcs/h |

| Power | 6kw |

| Sheet thickness | 0.3-1.2mm |

You can now ask our project managers for technical details

The Injera Making Machine can produce high-quality Injera efficiently and in large quantities, with a capacity ranging from 800 to 6000 pieces per hour. Sharing the same advanced technology as the spring roll wrapper maker, this machine ensures consistent results with wrappers featuring regular shapes and uniform thickness.

Capable of producing both square and round Injera, the machine offers customizable sizes to meet diverse customer needs.With integrated functions such as automatic grouting, baking, forming, and cutting, this innovative machine not only boosts production output but also significantly reduces labor costs, making it an ideal choice for businesses aiming to scale up their operations.

Why does the injera making machine become so popular?

Injera, with its soft, spongy texture and slightly tangy flavor, has captured the hearts of food lovers around the world.

Made from teff flour—a gluten-free and nutrient-rich grain—this traditional Ethiopian flatbread is not only healthy but also versatile, pairing well with stews, curries, and vegetables.

Its unique role as both food and utensil in Ethiopian cuisine enhances its appeal in international kitchens and restaurants.

As the global appreciation for Ethiopian cuisine grows, so does the demand for authentic injera. To meet this rising demand efficiently and consistently, injera making machines have become increasingly popular.

These machines streamline production, ensure uniform quality, and significantly save time and labor, making them an ideal solution for commercial kitchens, bakeries, and food businesses aiming to serve injera at scale.

Key features of the injera making machine

- Durable construction. Crafted from stainless steel and specialized alloy cast iron, ensuring durability, deformation resistance, and adherence to strict food hygiene standards.

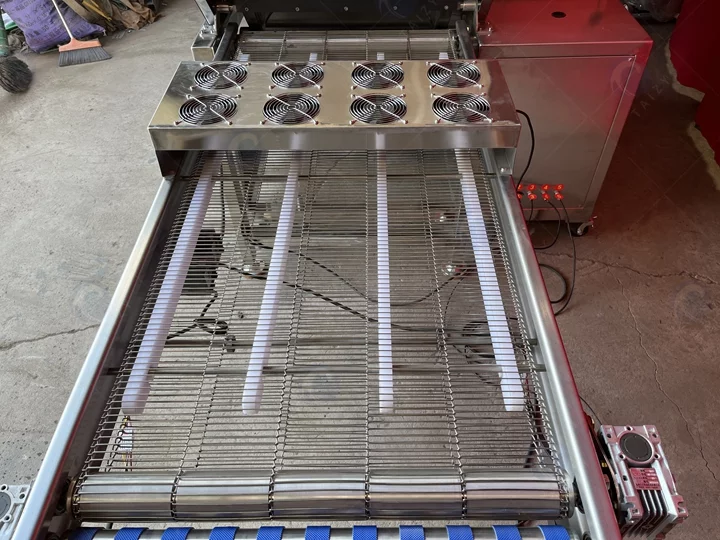

- Precision engineering. Equipped with a spray nozzle for uniform, thin Injera, and a microcomputer-based temperature control system for optimal softness and texture.

- Customizable options. Offers round and square molds, adjustable thickness, and customizable sizes from 10-60 cm to suit various needs.

- High automation. Features automatic grouting, baking, cutting, folding, stacking, and optional filling equipment to streamline production and save labor.

- Versatile design. Supports both two-phase and three-phase power, with multiple heating methods to cater to different preferences.

- Consistent output. Produces Injera with uniform thickness and size, making it ideal for commercial-scale production.

Customized injera maker machine

Our injera maker machine is designed for flexibility, allowing production in different shapes, sizes, and thicknesses to meet varied market needs. It’s ideal for restaurants, bakeries, and food factories with diverse production goals.

We offer tailor-made solutions based on customer requirements, ensuring consistent, high-quality results. Whether you need round or square injera, or specific dimensions, this machine provides a reliable and versatile solution for efficient injera production.

Supporting equipment of the injera making machine

Our injera making machine offers a range of options to cater to the diverse needs of our customers. Among these options, we provide the possibility of equipping the machine with a batter mixer and a pillow-type packaging machine. The batter mixer comes in two capacities, 30 liters, and 50 liters, and includes a stirring shaft for blending the batter ingredients.

Meanwhile, the pillow-type packaging machine offers a convenient packaging solution, capable of packaging ten pieces of Injera per package. These equipment options can be selected based on the specific production requirements and operational preferences of our customers, ensuring flexibility and customization to meet various demands.

Heating method of Ethiopian injera machine

- Electric heating

- Ideal for environments requiring precise temperature control.

- Allows easy temperature adjustments for consistent quality and texture in every batch.

- Gas heating

- Suitable for areas with limited or unreliable electricity supply.

- Provides efficient heating and helps reduce operating costs.

The option to choose between electric and gas heating offers flexibility, enabling users to adapt the machine to their specific production environment and achieve optimal results.

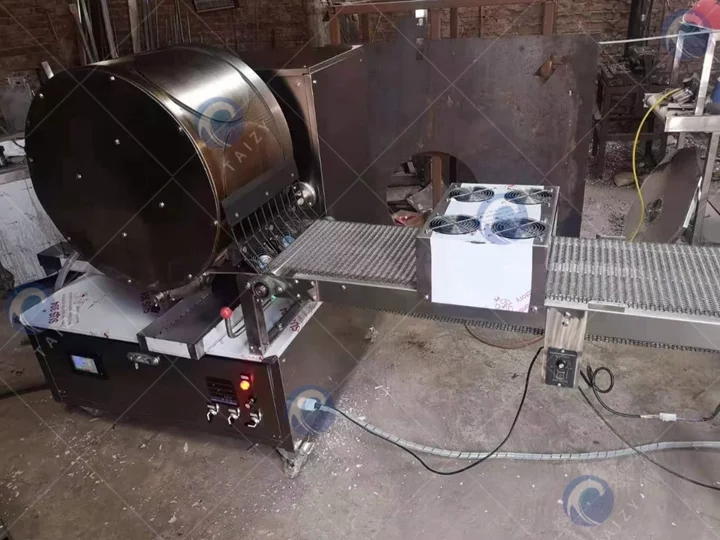

How does the injera making machine work?

- Automatic grouting. The machine automatically adsorbs the batter onto the baking pan.

- Baking and forming. The baking pan heats the batter to form and mature the Injera.

- Automatic removal. Once the baking pan turns, the machine’s shovel automatically removes the Injera.

- Cooling process. The Injera is placed on a conveyor belt to cool down after removal.

Injera maker machine price

- Customizable specifications – Price varies based on mold size, roller dimensions, conveyor length, heating methods, and added equipment.

- Key pricing factors – Customization level, extra features, and output capacity influence the final cost.

- Collaborative approach – We work with customers to balance performance, quality, and budget needs.

- Transparent pricing – Clear explanations of options and related costs ensure pricing transparency.

Contact us today to discuss your specific requirements and receive a customized quote for your ideal Injera maker machine.

Technical parameters of the injera making machine

| Model | TZ-3620 | TZ-5029 | TZ-8045 | TZ-12060 |

| Size | 1800*660*890mm | 2400*800*1350mm | 2800*1100*1600mm | 3100*1300*1800mm |

| Weight | 260kg | 520kg | 750kg | 850kg |

| Dia.of heat roller | 400*280mm | 500*330mm | 800*600mm | 1200*600mm |

| Electric power | 6kw | 13kw | 32kw | 48kw |

| Cutting power | 1kw | 1kw | 1kw | 1kw |

| Capacity | 800-1000pcs/h | 1500-2000pcs/h | 3000-4000pcs/h | 5000-6000pcs/h |

| Sheet max size | Round:250mm | Round:300mm | Round:400mm | Round:600mm |

| Sheet thickness | 0.3-1.2mm | 0.3-1.2mm | 0.3-1.2mm | 0.3-1.2mm |

Contact us

In conclusion, our Injera Making Machine offers exceptional versatility, efficiency, and customization options to meet the diverse needs of our customers. Whether you’re producing traditional Injera, pancakes, or crepes, our machine ensures consistent quality and high output, tailored to your specific requirements.

Additionally, if you’re interested in other food production solutions, we also offer the Spring Roll Wrapper Making Machine, designed to streamline your spring roll production process. Feel free to contact us for more details and a personalized quote today!