Chin Chin Making Machine

| Name | chin chin cutting machine |

| Voltage | 380v, 50Hz |

| Power | 3kw |

| Weight | 300kg |

| Size | 1060*750*1050mm |

| Capacity | 200kg/h |

| Thickness | 5-15mm |

You can now ask our project managers for technical details

Chin chin making machine line or chin chin production line is ideal for your restaurant, snack shops, coffee house, etc. It mainly consists of 6 machines, dough mixer, dough press machine, chin chin cutting machine, chin chin frying machine, de-oiling machine, and chin chin packing machine. These machine combines together, and can manufacture chin chin snacks automatically and efficiently.

The production capacity of chin chin making machine for sale from Taizy ranges from 150kg/h to 300kg/h. Besides, all machines use stainless steel body structure, which is food-grade and durable material. Welcome to contact us to start your chin chin snack business.

Raw materials of chin chin maker

The raw materials for making chin chin include: flour, sugar, butter or margarine, eggs, milk or water, baking powder or baking soda, spices (such as nutmeg or cinnamon), salt, and oil.

Chin chin production line process

The chin chin production line working process is as follows:

Dough mixing → dough pressing → chin chin cutting → chin chin frying → chin chin deoiling → chin chin packaging.

Main machines of the TAIZY chin chin making machine line

1. Dough mixer

In commercial chin chin production line, a dough mixer machine is generally used. It can mix a certain amount of flour and water at a time to get a mixed dough.

The mixing machine uses the rotation of the mixer to mix the flour and water until a large mixed dough is obtained. The whole machine is made of food-grade stainless steel material. Dough mixing machine output is 25kg, 50kg, 100kg, etc.

Parameters of dough mixer

- Capacity: 50kg/batch

- Time: 3-10min

- Voltage: 380v 50hz

- Power: 3kw

- Machine size: 1300*730*1100mm

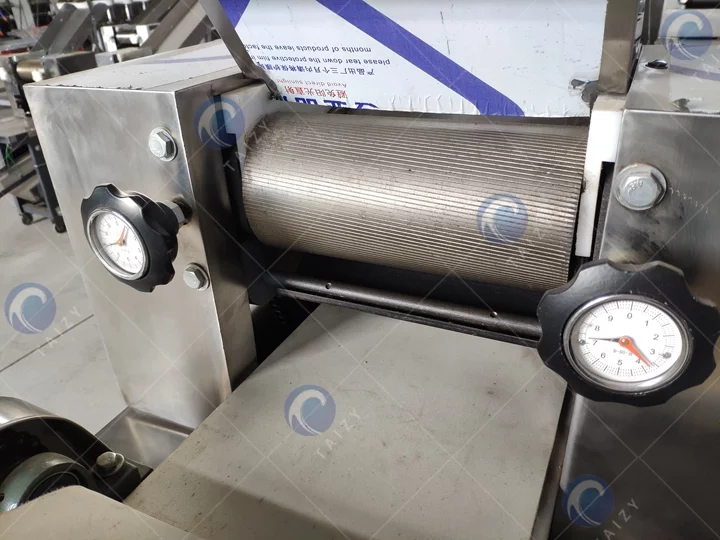

2. Dough pressing machine

The dough pressing machine repeatedly presses the pasta through the process of pasta conveying, kneading, pressing, and folding.

It replaces the complicated process of traditional manual kneading. It greatly reduces the labor intensity and improves productivity. In addition, the repeatedly pressed crust is smoother, more delicate, and more refreshing.

Dough pressing machine parameters

- Voltage: 380v 50Hz

- Power: 3kw

- Weight: 200kg

- Size: 1060*750*1050mm

- Width <480mm

- Thickness: 5-15mm

- Capacity: 200kg/h

3. Chin chin cutter machine

The chin chin cutter machine is applied for pressing and cutting dough sheets into small pieces. The size and thickness of the finished products can be customized according to preferences.

Additionally, the chin chin cutter machine can cut dough into various shapes such as squares, diamonds, and strips by changing the cutting blades.

Chin chin cutter machine technical parameters

- Voltage: 380v,50hz

- Power: 2.6kw

- Capacity: 150~300kg/h

- Weight: 170kg

- Size: 1500*560*1200mm

- Width range: 1.5-15mm; different widths, you can achieve it by changing the cutter.

4. Chin chin frying machine

Chin chin Fryer is used for frying chin chin to ripen and shape it. A wide variety of chin chin fryer options are available to you, such as box fryer, circular fryer, and continuous mesh belt fryer. They have different degrees of automation.

Semi-automatic chin chin production line can choose from box-type and round-type fryers. Continuous mesh belt fryers are usually used in chin chin processing plants for large production demand.

Chin chin frying machine parameters

- Heating power: 12kw

- Machine weight: 150kg

- Size of basket: 500*500mm

- Size: 700*700*950mm

- Capacity: about 50 kg/h

5. De-oiling machine

To avoid a large amount of fat adhering to the chin chin after frying, which affects the taste of chin chin. It needs a degreasing machine to remove the excess fat from the chin chin.

The de-oiling machine usually adopts the centrifugal principle for de-oiling. The degreasing time can be timed and an alarm device can be added to remind.

De-oiling machine parameters

- Capacity: 100-200kg/h

- Dimension: 1100*500*850mm

- Voltage: 380V, 50hz

- Power: 1.1kw

- Weight: 150kg

6. Chin chin packing machine

Chin chin packing machine is a kind of granule pouch packing machine. It has the function of automatically weighing, filling, bag making, coding, and sealing.

In Taizy factory, we provide two different types of chin chin packing machines, small vertical granule packing machines and multi-head weigher packing machines. They have different features and benefits. And they are suitable for different production requirements.

The small granule packaging machine is ideal for small production capacity, and the multihead weigher packaging machine has quite high productivity and is suitable for large production needs.

Parameters of chin chin packing machine

- Bag style: back seal

- Packing speed: 32-72bag/min or 100-130 bag/min

- Bag length: 30-180mm

- Bag width: 25-145mm (need replace the former)

- Filling range: 22-220ml

- Power: 1.8kw

- Size: 650*1050*1950mm

- Weight: 250kg

Features of automatic chin chin production line

- Simple structure and reasonable design, easy to operate

- Available in semi-automatic and fully automatic models with different specifications to suit various production requirements

- Wide range of applications; can produce rice noodles, honey three knives, etc., by changing different cutters

- Uniform shape, uniform cutting, good shape, and no waste of dough

- High level of automation, ensuring high efficiency

- Equipped with a vibrating screen to prevent the cut dough from sticking

Why is chin chin so popular in Nigeria?

Chin chin is very a popular fried noodle snack in West African countries, especially in Nigeria, and Ghana. In these West African countries, Chin chin is a snack that is often eaten at parties and during leisure time. Because it is easy to make, it can be eaten anytime and anywhere, and it is very tasty.

As a result, the production and operation of chin chin have gradually expanded from West African countries to the United Kingdom, the United States, the Philippines, and many other countries and regions.

Conclusion

In conclusion, our Chin Chin Making Machine offers a simple, efficient, and versatile solution for your snack production needs.

With its user-friendly design, wide range of applications, and high level of automation, it’s the perfect choice for businesses looking to streamline their production process while maintaining high-quality standards.

Contact us now for more information and to request a quote!