Máy làm cằm

| Tên | máy cắt cằm cằm |

| Vôn | 380v, 50Hz |

| Quyền lực | 3kw |

| Cân nặng | 300kg |

| Kích cỡ | 1060*750*1050mm |

| Dung tích | 200kg/giờ |

| Độ dày | 5-15mm |

Bây giờ bạn có thể hỏi người quản lý dự án của chúng tôi để biết chi tiết kỹ thuật

Máy làm cằm cằm Dây chuyền sản xuất chin chin lý tưởng cho nhà hàng, cửa hàng đồ ăn nhẹ, quán cà phê, v.v. Nó chủ yếu bao gồm 6 máy, máy trộn bột, máy ép bột, máy cắt chin chin, máy chiên chin chin, máy tách dầu và máy đóng gói chin chin. Những máy này kết hợp với nhau và có thể sản xuất đồ ăn nhẹ chin chin một cách tự động và hiệu quả.

Công suất sản xuất của máy làm chin chin bán từ Taizy dao động từ 150kg/h đến 300kg/h. Ngoài ra, tất cả các máy đều sử dụng cấu trúc thân bằng thép không gỉ, là vật liệu an toàn thực phẩm và bền. Chào mừng bạn liên hệ với chúng tôi để bắt đầu kinh doanh đồ ăn vặt chin chin của bạn.

Nguyên liệu thô của máy làm chin chin

Nguyên liệu thô để làm chin chin bao gồm: bột mì, đường, bơ hoặc margarine, trứng, sữa hoặc nước, bột nở hoặc baking soda, gia vị (như nhục đậu khấu hoặc quế), muối và dầu.

Quy trình sản xuất dây chuyền cằm cằm

Quy trình làm việc của dây chuyền sản xuất chin chin như sau:

Trộn bột → ép bột → cắt cằm → chiên cằm → khử dầu cằm → đóng gói cằm cằm.

Các máy chính của dòng máy làm cằm TAIZY

1. Máy trộn bột

Trong dây chuyền sản xuất chin chin thương mại, thường sử dụng máy trộn bột. Nó có thể trộn một lượng bột và nước nhất định cùng một lúc để có được một khối bột trộn.

Máy trộn sử dụng sự quay của máy trộn để trộn bột và nước cho đến khi thu được một khối bột trộn lớn. Toàn bộ máy được làm bằng vật liệu thép không gỉ an toàn thực phẩm. Công suất máy trộn bột là 25kg, 50kg, 100kg, v.v.

Thông số của máy trộn bột

- Công suất: 50kg/mẻ

- Thời gian: 3-10 phút

- Điện áp: 380v 50hz

- Công suất: 3kw

- Kích thước máy: 1300*730*1100mm

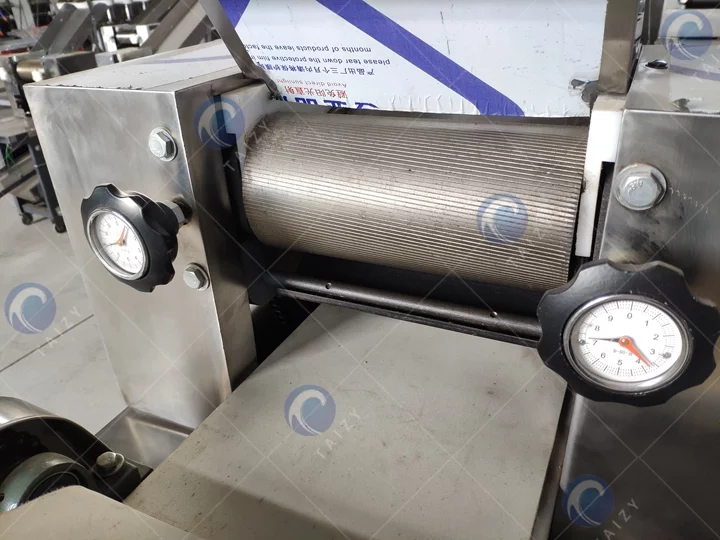

2. Máy ép bột

Máy ép bột thực hiện quá trình ép bột qua các bước vận chuyển bột, nhào, ép và gấp.

Nó thay thế quy trình nhào bột thủ công phức tạp. Nó giảm đáng kể cường độ lao động và cải thiện năng suất. Ngoài ra, lớp vỏ được ép lại mịn màng hơn, tinh tế hơn và tươi mát hơn.

Thông số máy ép bột

- Điện áp: 380v 50Hz

- Công suất: 3kw

- Trọng lượng: 200kg

- Kích thước: 1060*750*1050mm

- Chiều rộng <480mm

- Độ dày: 5-15mm

- Công suất: 200kg/h

3. Máy cắt chin chin

Các máy cắt cằm được áp dụng để ép và cắt các tấm bột thành những miếng nhỏ. Kích thước và độ dày của sản phẩm hoàn thiện có thể được tùy chỉnh theo sở thích.

Ngoài ra, máy cắt chin chin có thể cắt bột thành nhiều hình dạng khác nhau như hình vuông, hình thoi và dải bằng cách thay đổi lưỡi cắt.

Thông số kỹ thuật máy cắt chin chin

- Điện áp: 380v,50hz

- Công suất: 2.6kw

- Công suất: 150~300kg/h

- Trọng lượng: 170kg

- Kích thước: 1500*560*1200mm

- Phạm vi chiều rộng: 1.5-15mm; các chiều rộng khác nhau, bạn có thể đạt được bằng cách thay đổi lưỡi cắt.

4. Máy chiên chin chin

Máy chiên chin chin được sử dụng để chiên chin chin cho chín và định hình. Có nhiều loại máy chiên chin chin khác nhau cho bạn lựa chọn, chẳng hạn như máy chiên hộp, máy chiên tròn và máy chiên băng tải liên tục. Chúng có các mức độ tự động hóa khác nhau.

Dây chuyền sản xuất chin chin bán tự động có thể chọn từ máy chiên kiểu hộp và kiểu tròn. Máy chiên băng tải liên tục thường được sử dụng trong các nhà máy chế biến chin chin cho nhu cầu sản xuất lớn.

Thông số máy chiên chin chin

- Công suất nhiệt: 12kw

- Trọng lượng máy: 150kg

- Kích thước giỏ: 500*500mm

- Kích thước: 700*700*950mm

- Công suất: khoảng 50 kg/h

5. Máy tách dầu

Để tránh một lượng lớn chất béo bám vào chin chin sau khi chiên, điều này ảnh hưởng đến hương vị của chin chin. Cần có một máy tách dầu để loại bỏ lượng chất béo dư thừa từ chin chin.

Máy tách dầu thường áp dụng nguyên lý ly tâm để tách dầu. Thời gian tách dầu có thể được hẹn giờ và có thể thêm thiết bị báo động để nhắc nhở.

Thông số máy tách dầu

- Công suất: 100-200kg/h

- Kích thước: 1100*500*850mm

- Điện áp: 380V, 50hz

- Công suất: 1.1kw

- Trọng lượng: 150kg

6. Máy đóng gói chin chin

Máy đóng gói cằm cằm là một loại máy đóng gói túi hạt. Nó có chức năng tự động cân, đổ đầy, làm túi, mã hóa và niêm phong.

Trong Nhà máy taizy, chúng tôi cung cấp hai loại máy đóng gói chin chin khác nhau, máy đóng gói hạt nhỏ đứng và máy đóng gói cân đa đầu. Chúng có các tính năng và lợi ích khác nhau. Và chúng phù hợp với các yêu cầu sản xuất khác nhau.

Máy đóng gói hạt nhỏ là lý tưởng cho công suất sản xuất nhỏ, và máy đóng gói cân đa đầu có năng suất khá cao và phù hợp cho nhu cầu sản xuất lớn.

Thông số máy đóng gói chin chin

- Kiểu túi: niêm phong mặt sau

- Tốc độ đóng gói: 32-72 túi/phút hoặc 100-130 túi/phút

- Chiều dài túi: 30-180mm

- Chiều rộng túi: 25-145mm (cần thay thế khuôn trước)

- Phạm vi đổ đầy: 22-220ml

- Công suất: 1.8kw

- Kích thước: 650*1050*1950mm

- Trọng lượng: 250kg

Đặc điểm của dây chuyền sản xuất cằm cằm tự động

- Cấu trúc đơn giản và thiết kế hợp lý, dễ vận hành

- Có sẵn trong các mẫu bán tự động và hoàn toàn tự động với các thông số kỹ thuật khác nhau để phù hợp với các yêu cầu sản xuất khác nhau

- Phạm vi ứng dụng rộng; có thể sản xuất mì gạo, ba dao mật ong, v.v., bằng cách thay đổi các lưỡi cắt khác nhau

- Hình dạng đồng nhất, cắt đồng nhất, hình dạng đẹp và không lãng phí bột

- Mức độ tự động hóa cao, đảm bảo hiệu suất cao

- Được trang bị màn rung để ngăn bột đã cắt dính lại với nhau

Tại sao cằm cằm lại phổ biến ở Nigeria?

Chin chin là một món ăn vặt chiên rất phổ biến ở các nước Tây Phi, đặc biệt là ở Nigeria và Ghana. Ở những nước Tây Phi này, Chin chin là một món ăn thường được ăn trong các bữa tiệc và trong thời gian rảnh rỗi. Bởi vì nó dễ làm, có thể ăn bất cứ lúc nào và ở bất cứ đâu, và nó rất ngon.

Kết quả là, sản xuất và hoạt động của chin chin đã dần dần mở rộng từ các nước Tây Phi sang Vương quốc Anh, Hoa Kỳ, Philippines và nhiều quốc gia và khu vực khác.

Phần kết luận

Tóm lại, máy làm Chin Chin của chúng tôi cung cấp một giải pháp đơn giản, hiệu quả và đa năng cho nhu cầu sản xuất đồ ăn vặt của bạn.

Với thiết kế thân thiện với người dùng, phạm vi ứng dụng rộng và mức độ tự động hóa cao, đây là lựa chọn hoàn hảo cho các doanh nghiệp muốn tối ưu hóa quy trình sản xuất trong khi vẫn duy trì tiêu chuẩn chất lượng cao.

Liên hệ với chúng tôi ngay bây giờ để biết thêm thông tin và yêu cầu báo giá!