Chin Chin Cutting Machine

| Model | TZ-150 |

| Voltage | 220V |

| Power | 2.6kw |

| Capacity | 150-300kg/h |

| Weight | 280kg |

| Size | 1500*560*1200mm |

You can now ask our project managers for technical details

The electric Chin Chin cutting machine is a key piece of equipment in the Chin Chin production line, designed to streamline the process of creating this popular Nigerian snack.

By automating the cutting of dough into consistent shapes, such as squares, strips, or diamond-shaped pieces, this machine ensures uniformity and high efficiency.

This versatile machine is not only ideal for producing Chin Chin but is also widely used in the production of rice noodles, honey three knives, and other snack items.

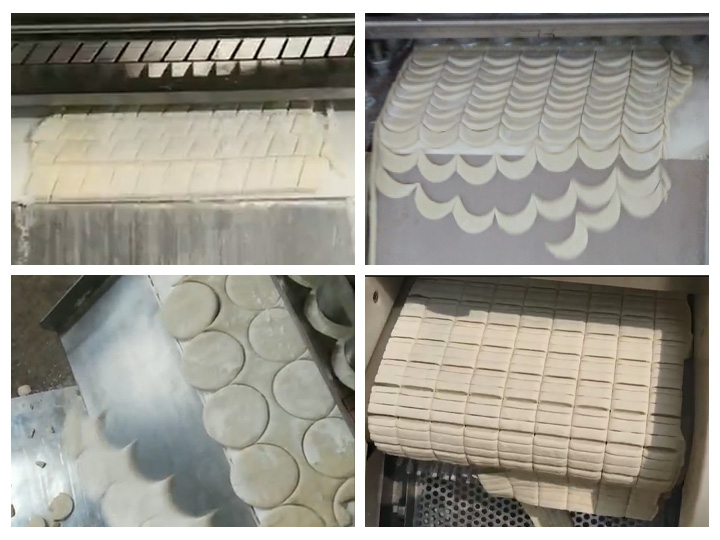

Various types of chin chin

The chin chin cutting machine offers great flexibility in producing various types of snacks by simply changing the forming tools. With different sizes and shapes of molds, the machine can easily create not only traditional chin chin in square or strip shapes but also other popular snacks like honey three knives, rice strips, and smiles.

This versatility makes the machine highly adaptable for different production needs, allowing manufacturers to expand their product range and meet diverse market demands with ease.

Chin chin cutting machine features

- Multi-function cutting. By changing blades, the machine can produce chin chin, honey three knives, rice noodles, and other snacks.

- Automatic flour sprinkling. Front and back flour-spreading devices prevent sticking, with adjustable flour amounts.

- Vibrating sieve design. Separates finished products from excess flour for a cleaner output.

- Stable and reliable. Simple mechanical structure, low failure rate, and uniform cutting without material waste.

- Easy to operate. One person can complete feeding, with the machine handling all cutting automatically.

- High efficiency. Large capacity, compact size, and greatly reducing labor and production costs.

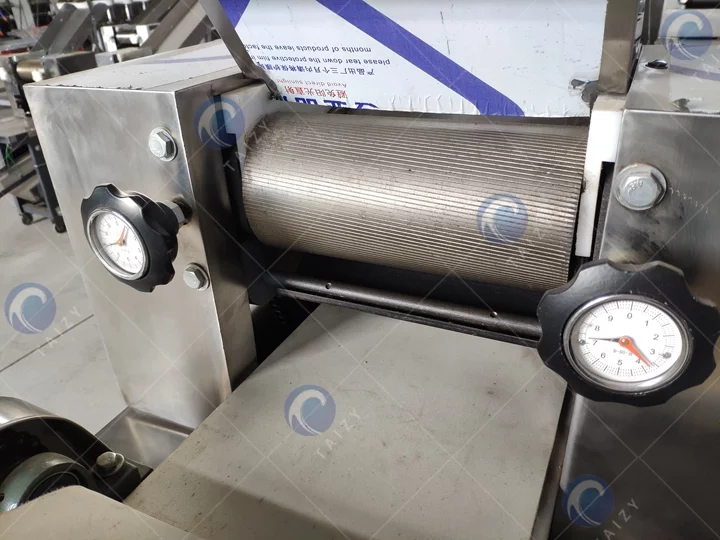

- Adjustable size and thickness. Finished product size and dough sheet thickness can be easily adjusted via rollers and handles.

Parameters of chin chin cutting machine

| Type | TZ-150 | TZ-1000 |

| Power | 2.6kw | 4.5kw |

| Capacity | 150~300kg/h | 1000kg/h |

| Weight | 280kg | 800kg |

| Size | 1500*560*1200mm | 3300*610*1500mm |

How does chin chin cutter work?

- Place the dough sheet onto the feeding area of the machine.

- Start the machine and the dough will be automatically conveyed between the rollers.

- The rollers press the dough to the desired thickness, which can be adjusted as needed.

- Pressed dough is delivered onto the conveyor belt leading to the cutting section.

- The dough sheet passes through the cutter, where it is sliced into squares, diamonds, moons, or other shapes.

- Each roller’s position can be adjusted to control the dough thickness, helping manage the final size and weight of the chin chin.

- After cutting, the finished pieces are separated and ready for the next processing stage.

Why are chin chin snacks so popular?

Chin chin snacks are loved for their delicious taste, crispy texture, and versatility. They can be enjoyed as a light snack, a party treat, or even packaged for commercial sale. With a sweet, slightly buttery flavor and a satisfying crunch, chin chin appeals to people of all ages.

Their long shelf life, ease of storage, and variety of shapes and sizes also add to their popularity. Whether homemade or mass-produced, chin chin remains a favorite snack across many cultures, especially in Africa and beyond.

Contact us

In summary, our Chin Chin Cutting Machine not only produces various shapes and flavors of Chin Chin but also operates with ease and high automation, enhancing production efficiency while maintaining product quality.

Moreover, when paired with our advanced Chin Chin Making Production Line, you can achieve automation and large-scale production, bringing great convenience and profit growth to your business. Contact us now for more information and to request a quote!