Peanut peeling machine

| Model | TZ-GT-4 |

| Power | 0.75KW |

| Size | 1100x400x1100mm |

| Peeling rate | 98% |

| Capacity | 200kg/h |

You can now ask our project managers for technical details

Peanut peeling machine in Taizy is available in two types: dry peeling and wet peeling, designed to meet various processing needs. The wet peeling machine uses a high-quality pure rubber soft roller, effectively removing the red skin of peanuts and suitable for various materials, such as peanuts and broad beans.

The dry peeling machine is ideal for removing the red coat from peanuts, achieving a peeling rate of over 97%. It offers short processing times and high work efficiency, making it an indispensable machine in peanut deep processing.

Dry peanut peeler machine

The dry peanut peeler machine is a highly efficient device designed for removing the red skin from peanuts. Its construction includes several key components, such as a power device (motor, pulley, belt, and bearing), a sturdy frame, a feeding hopper, a peeling roller (either steel or diamond), and a fan system.

Working principle

The machine operates on the principle of differential rolling friction transmission. It is optimized for use with peanuts that have a moisture content of less than 5%, ensuring that the nuts do not become pasty during processing.

Operation steps

- Feeding. Peanuts are loaded into the machine via the feeding hopper.

- Peeling. As the peanuts move through, they are rubbed against the peeling roller, effectively separating the skin from the kernels.

- Separation. A fan system removes the detached peanut skins, while a vibrating screen sorts the output into whole peanut kernels, half kernels, and broken pieces.

Dry groundnut skin removing machine parameters

| Model | Power | Size | Capacity | Peeling rate |

| TZ-GT-4 | 0.75KW | 1100x400x1100mm | 200kg/h | 98% |

| TZ-GT-8 | 1.5KW | 1100x600x1100mm | 400kg/h | 96% |

| TZ-GT-12 | 2.61KW | 1180x900x1100mm | 600kg/h | 96% |

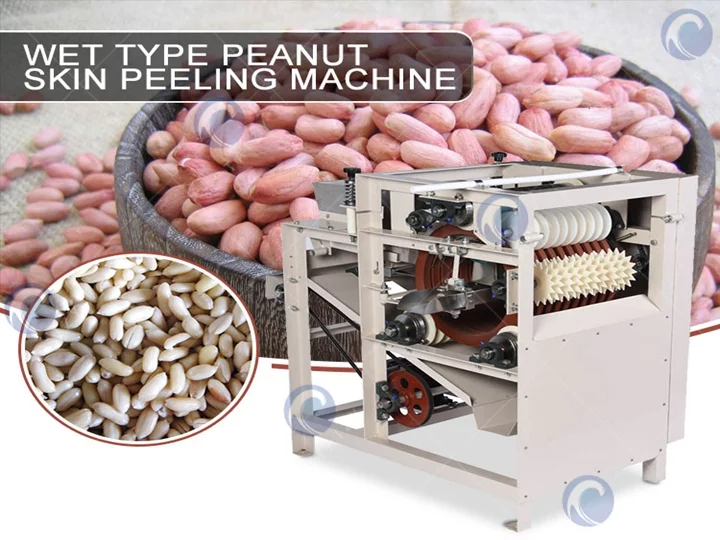

Wet peanut peeler machine

The wet peanut peeler machine is specifically designed for the efficient removal of peanut and almond skins, utilizing a specialized peeling process that ensures high quality and minimal breakage.

This equipment operates on the principle of differential rolling friction transmission, providing a reliable solution for nut processing.

Working principle

- Soaking. Prior to peeling, raw materials must be soaked in hot water. The required soak time and temperature vary based on the type of nut.

- Feeding. After soaking, the almonds or peanuts are poured into the hopper, where they are vibrated into a rotating rubber wheel, which is fixed with three robust rollers.

- Peeling process. The peeling action is achieved through an inducing strip, a feeding wheel, and an imitation hand-turning mechanism, ensuring effective skin removal.

- Discharge. The discharge wheel pushes the peeled almonds into the discharge hopper, while the almond skins are expelled through the suede wheel.

Wet groundnut peeling machine parameters

| Model | Power | Size | Capacity | Peeling rate |

| TZ-100 | 0.55KW | 1180*720*1100mm | 120-150kg/h | 98% |

| TZ-180 | 0.75KW | 1180*850*1100mm | 200-250kg/h | 96% |

Groundnut peeler machine features

Low breakage rate. The wet peeling process minimizes damage, resulting in superior quality nuts.

Color and nutritional integrity. The surface color of the peeled nuts remains unchanged, and essential proteins are preserved.

Automatic separation. The machine efficiently separates and discharges the skins and nuts automatically during the peeling process.

Compact and efficient. Its small size, low energy consumption, and high efficiency make it easy to operate.

Reliable performance. The machine boasts stable operation, safety, high productivity, excellent peeling effects, and a low rate of half kernels.

Peanut peeling machine applications

The peanut peeling machine is highly versatile and finds applications across various industries that require the efficient peeling of nuts and legumes.

- Snack food production. Ideal for preparing peeled peanuts and almonds used in various snacks and packaged foods.

- Peanut butter manufacturing. Ensures smooth, skin-free peanuts for high-quality peanut butter production.

- Baking and confectionery. Provides perfectly peeled nuts for use as ingredients in baked goods and confectioneries.

- Nut processing plants. Used in large-scale facilities to handle bulk nut peeling with high efficiency.

Invest in our peanut peeling machine

In conclusion, the peanut peeling machine offers a versatile and efficient solution for nut processing with its high peeling rate, low breakage, and ability to handle various materials like peanuts, almonds, and broad beans.

In addition to the peanut peeling machine, we also provide a range of other nuts processing machines, such as roasting machines, offering complete solutions to streamline your production line while maintaining high product quality.