เครื่องบีบน้ำมัน

| รุ่น | 6YZ-180 |

| ความจุ | 30กก./ชม. |

| น้ำหนัก | 750 กก. |

| ขนาด | 500*650*1050mm |

| พลังงาน | 2 กิโลวัตต์ |

| แรงดัน | 55Mpa |

คุณสามารถสอบถามผู้จัดการโครงการของเราเกี่ยวกับรายละเอียดทางเทคนิคได้แล้ว

เครื่องบีบน้ำมัน สามารถแยกน้ำมันจากเมล็ดและถั่วต่างๆ ได้อย่างมีประสิทธิภาพ ใช้กันอย่างแพร่หลายในการประมวลผล ถั่วลิสง ถั่วเหลือง เมล็ดรำ ข้าวฟ่าง วอลนัท มะพร้าว และวัตถุดิบที่มีน้ำมันอื่นๆ

เพื่อตอบสนองความต้องการที่หลากหลายของผู้ใช้และสภาพแวดล้อมการผลิตที่แตกต่างกัน บริษัทของเรามีเครื่องบีบน้ำมัน ที่หลากหลาย เรามีโมเดลหลักสี่แบบ: เครื่องบีบน้ำมันกึ่งอัตโนมัติ, เครื่องบีบน้ำมันอุณหภูมิคู่, เครื่องบีบน้ำมันแบบเกลียว และ เครื่องบีบน้ำมันไฮดรอลิก

แตกต่างจากวิธีการสกัดทางเคมี กระบวนการทางกลนี้ช่วยรักษาสารอาหาร กลิ่น และรสชาติของน้ำมันตามธรรมชาติ ทำให้เป็นตัวเลือกที่ชื่นชอบสำหรับทั้งผู้ผลิตเชิงพาณิชย์และผู้ใช้ที่ใส่ใจสุขภาพ

เครื่องบีบน้ำมันกึ่งอัตโนมัติ

เครื่องบีบน้ำมันกึ่งอัตโนมัติ ของเราเป็นโซลูชันที่แข็งแกร่งและปรับตัวได้ซึ่งออกแบบมาสำหรับผู้ผลิตน้ำมันขนาดเล็กถึงขนาดกลางที่ต้องการประสิทธิภาพพร้อมการทำงานอัตโนมัติที่จัดการได้

ออกแบบมาเพื่อจัดการกับ วัสดุที่มีน้ำมันหลากหลาย โมเดลนี้ประมวลผลพืชผลยอดนิยม เช่น ถั่วลิสง, เมล็ดงา, เมล็ดรำ (คาโนล่า) และเมล็ดน้ำมันอื่นๆ ที่คล้ายกัน

ให้ประสิทธิภาพที่สม่ำเสมอซึ่ง ผลผลิตน้ำมันสุดท้ายขึ้นอยู่กับคุณภาพและปริมาณน้ำมันที่มีอยู่ในวัสดุที่ป้อน

Key features & operation

- Core mechanism. Utilizes a powerful screw rotation system to apply continuous, high pressure for effective oil extraction.

- Power flexibility. Offers exceptional operational versatility by being compatible with both electric motors and diesel engines, making it suitable for locations with varying power infrastructure.

- Output characteristic. The extraction process efficiently separates oil, but the pressed cake may contain more residual impurities, requiring further filtration.

- Unique value-add function. A key advantage is its ability for secondary pressing, allowing hot oil cake to be repressed for higher oil yield and reduced waste.

Positioning & target users

เครื่องบีบน้ำมันกึ่งอัตโนมัติ นี้ ให้ความสมดุลที่เหมาะสมระหว่าง ความสามารถในการจ่าย, ความเรียบง่ายในการทำงาน และ ความหลากหลาย

It’s an excellent choice for farmers, homesteaders, and small commercial oil mills looking for a dependable, cost-effective entry into oil production or requiring a flexible machine capable of handling multiple seed types without complex setup.

พารามิเตอร์ของเครื่อง

| รุ่น | ความจุ(t/24h) | ความเร็วในการหมุน(rpm) | พลังงาน(กิโลวัตต์) | ขนาด(mm) | น้ำหนัก(กก.) |

| 6YL-68 | 0.8-1 | 30-40 | 5.5 | 880*440*770 | 160 |

| 6YL-80 | 2-3 | 30-40 | 5.5 | 1510*440*770 | 360 |

| 6YL-95 | 3.5-4 | 30-40 | 7.5 | 1640*640*1200 | 460 |

| 6YL-100 | 3-5 | 30-40 | 7.5 | 1640*640*1200 | 480 |

| 6YL-120 | 4-6 | 30-40 | 11 | 1760*640*1300 | 600 |

| 6YL-130 | 9-12 | 30-40 | 15-18.5 | 1950*680*1490 | 800 |

| 6YL-165 | 15-20 | 28-38 | 22-30 | 2300*850*1560 | 1100 |

เครื่องสกัดน้ำมันอุณหภูมิคู่

เครื่องสกัดน้ำมันแบบอุณหภูมิคู่ หรือที่เรียกว่าเครื่องกดน้ำมันแบบร้อนและเย็นอัตโนมัติเต็มรูปแบบ ถูกออกแบบมาเพื่อกดทั้งวัตถุดิบเย็นและวัตถุดิบที่คั่วร้อน

เหมาะสำหรับการสกัดน้ำมันหลากหลายชนิด เช่น น้ำมันงา น้ำมันเมล็ดดอกทานตะวัน น้ำมันถั่วลิสง น้ำมันรำข้าว น้ำมันละหุ่ง น้ำมันเมล็ดฝ้าย น้ำมันถั่วเหลือง น้ำมันวอลนัท น้ำมันอัลมอนด์ น้ำมันสน น้ำมันเมล็ดแฟลกซ์ และน้ำมันเมล็ดอัลฟัลฟา。

Key advantages

- ความสามารถในการปรับวัสดุได้กว้าง

- Unlike conventional presses, this machine allows hot pressing of sunflower seeds, peanuts, castor seeds, and cotton seeds without pre-shelling or roasting, reducing equipment costs and simplifying the process.

- รักษาคุณค่าทางโภชนาการและคุณภาพ

- การบีบเย็นช่วยรักษาสารอาหารตามธรรมชาติในเมล็ดน้ำมันได้ดีกว่า

- น้ำมันที่บีบเย็นจะบริสุทธิ์มากขึ้นและมีสีที่สดใสกว่า

- สร้างควันน้อยในระหว่างการปรุงอาหารและได้รับการยอมรับว่าเป็นสุขภาพที่ดีกว่า

- อัตโนมัติและประสิทธิภาพ

- Equipped with an automatic screw conveyor, significantly saving labor.

- Features an oil residue recycling system to reuse residue and improve oil yield.

- การกรองแบบรวม

- Includes dual vacuum filters, directly filtering the pressed oil without needing an extra oil filter machine.

ข้อมูลทางเทคนิค

| รุ่น | ZY-125 | ZY-150 |

| กำลังมอเตอร์หลัก | 15 กิโลวัตต์ | 37 กิโลวัตต์ |

| กำลังปั๊มสุญญากาศ | 1.5 กิโลวัตต์ | 2.2 กิโลวัตต์ |

| ความสามารถในการประมวลผล | 150-200 กก./ชม. | 300-350 กก./ชม. |

| น้ำหนักเครื่อง | 986 กก. | 2500 กก. |

| ขนาด (ยาวxกว้างxสูง) | 1900x1100x1500 มม. | 2100x1300x1700 มม. |

เครื่องบีบอัดน้ำมันแบบเกลียว

เครื่องบีบน้ำมันแบบเกลียว เป็นโมเดลการบีบร้อนอัตโนมัติเต็มรูปแบบ เหมาะสำหรับการดำเนินงานการสกัดน้ำมันเชิงพาณิชย์ที่ต้องการประสิทธิภาพสูงและผลผลิตที่สม่ำเสมอ

เครื่องนี้รวมการควบคุมอุณหภูมิอัจฉริยะ ความดันสูง และการกรองที่มีประสิทธิภาพเพื่อให้ได้ผลผลิตน้ำมันและคุณภาพที่เหนือกว่า

Key features

- Hot pressing with preheating. Equipped with an electric heating ring, the machine can preheat before operation, ensuring optimal temperature for efficient oil extraction.

- Internal screw structure. A continuous screw shaft บีบและกดน้ำมันจากเมล็ด เพิ่มผลผลิตและลดของเสีย.

- ถังกรองน้ำมันแบบสูญญากาศ. มาพร้อมกับ กรองสูญญากาศในตัว เพื่อทำให้บริสุทธิ์น้ำมันที่สกัดได้อย่างรวดเร็ว โดยการกำจัดสิ่งสกปรกและปรับปรุงความใส.

- ขับเคลื่อนด้วยมอเตอร์ไฟฟ้าโมเดลนี้ทำงานด้วยพลังงานไฟฟ้าเท่านั้น ไฟฟ้า, ให้การทำงานที่มั่นคงและเงียบ—เหมาะสำหรับโรงงานหรือโรงงานแปรรูปสมัยใหม่.

- แท่งกดที่สามารถเปลี่ยนได้. ภายใน แท่งกด ถือเป็นวัสดุสิ้นเปลืองและเปลี่ยนได้ง่าย ทำให้การบำรุงรักษาในระยะยาวง่ายและคุ้มค่า.

- ผลผลิตน้ำมันสูง. เนื่องจากแรงกดที่แข็งแกร่งและกระบวนการที่มีความร้อน เครื่องนี้จึงให้ผลลัพธ์ที่ ผลผลิตน้ำมันสูงขึ้น เมื่อเปรียบเทียบกับรุ่นกึ่งอัตโนมัติหรือแบบกดเย็น.

พารามิเตอร์ของเครื่อง

| รุ่น | 6YL-60 | 6YL-70 | 6YL-100 | 6YL-125 |

| เส้นผ่านศูนย์กลางเกลียว (มม.) | Φ55 | Φ65 | Φ100 | Φ125 |

| ความเร็วการหมุนเกลียว (รอบ/นาที) | 64 | 38 | 37 | 34 |

| กำลังหลัก (กิโลวัตต์) | 2.2 | 3 | 7.5 | 15 |

| กำลังปั๊มสุญญากาศ (กิโลวัตต์) | 0.75 | 0.75 | 0.75 | 0.75 |

| กำลังความร้อน (กิโลวัตต์) | 0.9 | 1.8 | 3 | 3.75 |

| ความจุ(กก./ชม.) | 40-60 | 50-70 | 150-230 | 300-350 |

| น้ำหนัก (กก.) | 240 | 280 | 1100 | 1400 |

| ขนาด (มม.) | 1280*880*1220 | 1400*900*1260 | 1900*1200*1300 | 2100*1300*1700 |

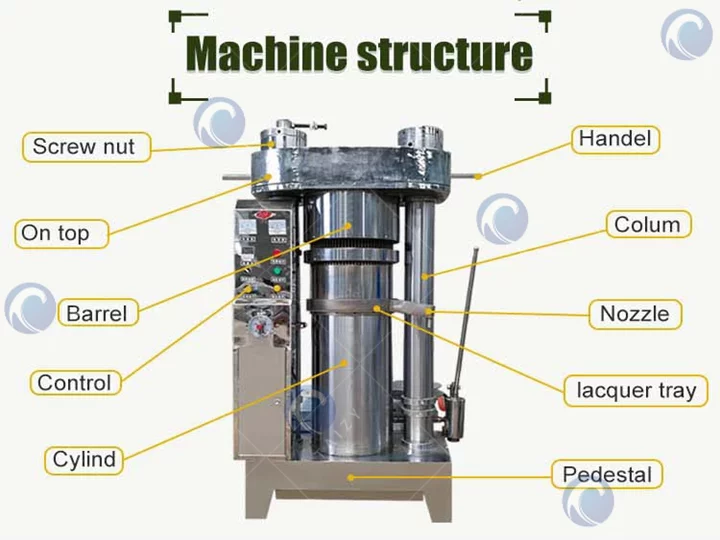

Hydraulic oil making machine

เครื่องผลิตน้ำมันไฮดรอลิก เป็นอุปกรณ์การกดเย็นที่ออกแบบมาเฉพาะสำหรับการสกัดน้ำมันจากวัตถุดิบที่มีน้ำมันสูง

แตกต่างจากรุ่นแบบสกรู เครื่องนี้ทำงานด้วย กระบอกไฮดรอลิก ที่มีพลัง ใช้แรงกดแนวตั้งผ่าน กลไกการกดขึ้นและลง—ทำให้การปล่อยน้ำมันช้า สม่ำเสมอ และมีประสิทธิภาพโดยไม่สร้างความร้อนมากเกินไป

เครื่องนี้เหมาะสำหรับ การผลิตน้ำมันคุณภาพสูง โดยเฉพาะเมื่อการรักษาสารอาหาร กลิ่น และรสชาติเป็นสิ่งสำคัญ

Key features

- ระบบไฮดรอลิกใช้กระบอกน้ำมันไฮดรอลิกในตัว กระบอกน้ำมันไฮดรอลิก เพื่อให้แรงกดที่แข็งแกร่งและสม่ำเสมอ เหมาะสำหรับเมล็ดน้ำมันที่บอบบาง.

- ไม่มีสกรูภายใน. การไม่มีเพลาสกรูช่วยให้กระบวนการกดน้ำมันสะอาดขึ้นโดยมีเศษเหลือน้อยที่สุดและไม่มีการบดทางกล.

- การเคลื่อนที่กดในแนวตั้ง. น้ำมันถูกสกัดออกผ่าน แรงดันน้ำขึ้นและลง, ทำให้กระบวนการเงียบ มีประสิทธิภาพ และควบคุมได้ง่าย.

- เหมาะสำหรับวัสดุพิเศษ. เหมาะสำหรับวัสดุที่มีน้ำมันสูง เช่น:

- งา

- อะโวคาโด

- วอลนัท

- มะพร้าว (เปลือกต้องถูกเอาออกและเนื้อจะต้องถูกบดก่อน)

- ข้อดีของการกดเย็น: รักษารสชาติและโปรไฟล์โภชนาการดั้งเดิมของน้ำมัน เหมาะสำหรับตลาดที่ใส่ใจสุขภาพ.

ด้วยโครงสร้างที่เรียบง่าย เสียงต่ำ และคุณภาพน้ำมันที่ยอดเยี่ยม เครื่อง ผลิตน้ำมันไฮดรอลิก จึงเป็นตัวเลือกที่ชื่นชอบสำหรับผู้ผลิตน้ำมันบูติก ห้องปฏิบัติการ หรือธุรกิจที่มุ่งเน้นการสกัดน้ำมันที่มีมูลค่าสูงในปริมาณน้อย

โครงสร้างของเครื่องผลิตน้ำมันไฮดรอลิก

พารามิเตอร์ของเครื่อง

| รุ่น | 6YZ-180 | 6YZ-230 | 6YZ-260 | 6YZ-320 |

| เส้นผ่านศูนย์กลางการป้อน | 180 มม. | 230 มม. | 260 มม. | 320 มม. |

| เส้นผ่านศูนย์กลางเค้กน้ำมัน | 180 มม. | 230 มม. | 260 มม. | 320มม. |

| พลังงาน | 2กิโลวัตต์ | 2กิโลวัตต์ | 2 กิโลวัตต์ | 2กิโลวัตต์ |

| แรงดัน | 55Mpa | 55Mpa | 55Mpa | 55Mpa |

| เวลาการบีบ | 7 นาที | 8 นาที | 10 นาที | 10 นาที |

| ความจุ (ต่อครั้ง) | 2-3 กก. | 7–8กก. | 10-12 กก. | 15กก. |

| ความจุ | 30กก./ชม. | 50กก./ชม. | 60kg/h | 90 กก./ชม. |

| ขนาด (มม.) | 500*650*1050 | 600*850*1360 | 650*900*1450 | 800*1100*1550 |

| น้ำหนัก | 750กก. | 1050กก. | 1400 กก. | 2000กก. |

อุปกรณ์สนับสนุนของเครื่องกดน้ำมัน

เครื่องบด มีบทบาทสำคัญในการเพิ่มประสิทธิภาพกระบวนการสกัดน้ำมันโดยรวม โดยเฉพาะเมื่อจัดการกับวัตถุดิบที่แข็งหรือมีเส้นใย เช่น เมื่อประมวลผล มะพร้าว จะต้อง เอาเปลือกออก และ บดเนื้อมะพร้าว ให้เป็นอนุภาคละเอียดเพื่อให้การกดน้ำมันราบรื่นและมีประสิทธิภาพ

เพื่อตอบสนองความต้องการนี้ เราขอเสนอ เครื่องบด ที่มีประสิทธิภาพสูงเป็นอุปกรณ์สนับสนุนหลักสำหรับสายการกดน้ำมันของเรา เครื่องบดเหล่านี้ออกแบบมาเพื่อจัดการกับวัสดุต่างๆ เช่น เนื้อมะพร้าว, เมล็ดปาล์ม, และเมล็ดน้ำมันแข็งอื่นๆ ซึ่งช่วยเพิ่มประสิทธิภาพการกดและป้องกันไม่ให้เครื่องกดน้ำมันหลักเกิดการอุดตันหรือการป้อนที่ไม่สม่ำเสมอ

โดยการรวม เครื่องบด ของเราเข้ากับ เครื่องกดน้ำมัน ผู้ใช้สามารถบรรลุ:

- ผลผลิตน้ำมันที่ดีกว่า ผ่านการเตรียมวัสดุที่ละเอียดขึ้น

- การสึกหรอทางกลที่ลดลง บนเครื่องกดเนื่องจากการให้อาหารที่สม่ำเสมอ

- ความเร็วในการประมวลผลที่เร็วขึ้น และประสิทธิภาพการผลิตโดยรวมที่ดีขึ้น

บทสรุป

โดยสรุป เครื่อง กดน้ำมัน ของเรา—ตั้งแต่แบบกึ่งอัตโนมัติไปจนถึงแบบสกรู แบบอุณหภูมิคู่ และแบบไฮดรอลิก—เสนอทางออกที่ยืดหยุ่นสำหรับความต้องการการผลิตและวัตถุดิบที่หลากหลาย

หากคุณกำลังมองหาที่จะเริ่มต้นหรือขยายการผลิตน้ำมันกินได้ โปรดติดต่อเราเพื่อขอคำแนะนำที่ปรับแต่งและใบเสนอราคาที่แข่งขันได้.