Машина для нарезки замороженного мяса

| Модель | TZ-MR-2 |

| Мощность | 2200w |

| Размер | 1200*560*1200мм |

| Вес | 200кг |

| Производительность | 50-300кг/ч |

| Напряжение | 220в |

Теперь вы можете спросить наших менеджеров проектов о технических деталях

Машина для нарезки замороженного мяса может нарезать замороженную говядину, баранину, свинину и другие мясные изделия на равномерные ломтики или рулеты без размораживания.

С производительностью от 50 кг до 1200 кг в час обеспечивает высокую эффективность и стабильные результаты, что делает ее идеальной для ресторанов, хот-пот заведений, мясных лавок и крупных мясоперерабатывающих предприятий.

Продается машина для нарезки замороженного мяса

Часто называемая слайсером для мяса, слайсером для баранины или машиной для резки говядины, она устраняет необходимость размораживания, обеспечивая при этом точную резку и равномерные результаты.

Эта машина выпускается в различных моделях для разных производственных задач: ЧПУ-ножи для точной резки, вертикальные и настольные слайсеры для экономии места, а также мульти-роликовые слайсеры с 2, 4 или 8 роликами.

Особенности машины для нарезки замороженного мяса

- Не требуется размораживание – напрямую нарезает замороженную говядину, баранину, свинину и другие виды мяса, экономя время и сохраняя свежесть.

- Регулируемая толщина – толщина нарезки легко настраивается для удовлетворения различных кулинарных или перерабатывающих требований.

- Высокий диапазон емкости – поддержка 50–1200 кг в час, подходит как для небольших магазинов, так и для крупных мясоперерабатывающих предприятий.

- Равномерная нарезка – обеспечивает однородный размер и форму мясных ломтиков или рулонов, идеально подходит для ресторанов горячего блюда и упакованных мясных продуктов.

- Прочная конструкция из нержавеющей стали – конструкция пищевого класса, устойчивая к коррозии и легкая в очистке для долгосрочного использования.

- Удобная эксплуатация – простое управление с высокими стандартами безопасности, снижает трудозатраты и повышает эффективность.

- Широкие применения – широко используется в ресторанах, мясных лавках, супермаркетах и цехах по переработке замороженного мяса.

Структуры машины для нарезки замороженного мяса

- Каркас и основание из нержавеющей стали – прочная конструкция, содержащая все компоненты.

- Камера нарезки – фиксирует замороженное мясо для точной нарезки и рулонной обработки.

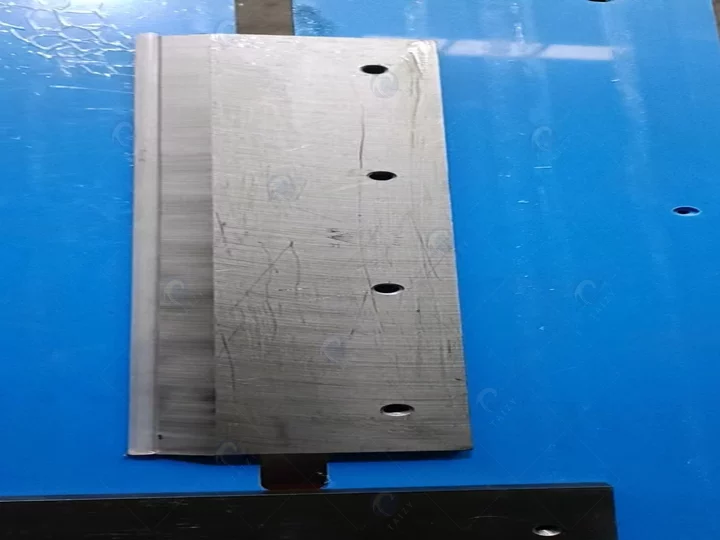

- Сборка лезвия – острый нож из нержавеющей стали для легкой нарезки замороженного мяса.

- Регулировка толщины – настраиваемая толщина среза для удовлетворения различных потребностей.

- Мощный мотор – обеспечивает плавную и эффективную работу нарезки.

- Система безопасности – аварийная остановка, блокировки и защитные крышки.

- Панель управления – легкая настройка и контроль параметров нарезки.

- Регулируемые ножки/колеса – стабильное размещение и удобная мобильность.

Как работает машина для нарезки замороженного мяса?

- Машина использует двухнаправленную систему подачи, которая автоматически продвигает и прессует замороженное мясо, одновременно регулируя толщину ломтика для равномерной резки.

- После завершения нарезки лезвие останавливается автоматически, а толкатель мяса безопасно втягивается.

- Нож и конвейерная лента работают синхронно, а при открытии защитной двери питание сразу отключается для обеспечения безопасности оператора.

Как использовать машину для нарезки замороженного мяса?

- Подготовьте и загрузите. Поместите замороженное мясо подходящего размера в загрузочный лоток.

- Установите толщину. Отрегулируйте толщину нарезки с помощью панели управления.

- Начните нарезку. Включите машину, чтобы начать автоматическую нарезку.

- Соберите ломтики. Соберите нарезанное мясо для приготовления или дальнейшей переработки.

- Очистите машину. Очистите и продезинфицируйте машину после использования, чтобы поддерживать гигиену и продлить срок службы.

Советы по использованию машины для нарезки замороженного мяса

- Убедитесь, что мясо правильно заморожено, но не слишком твердо — обычно при температурах выше -6°C. Если оно слишком твердое, дайте немного оттаять перед нарезкой.

- Всегда удаляйте кости из мяса, чтобы защитить лезвие от повреждений.

- Поместите мясо в машину перед установкой предпочитаемой толщины нарезки с помощью контрольного регулятора.

- Если лезвие плохо захватывает или режет неровно, оно может быть тупым или ржавым и нуждается в заточке для оптимальной работы.

Технические параметры машины для нарезки замороженного мяса

| Модель | Напряжение | Производительность | Мощность | Вес | Размер | Длина нарезки | Ширина нарезки |

| TZ-MR-2 | 220в | 50-300кг/ч | 2200w | 200кг | 1200*560*1200мм | 600 мм | 270мм |

| TZ-MR-4 | 380в | 50-600кг/ч | 3000Вт | 320 кг | 1200*800*1200мм | 600 мм | 510мм |

| TZ-MR-6 | 380в | 50-900кг/ч | 3000Вт | 400кг | 1200*1010*1200мм | 600 мм | 730мм |

| TZ-MR-8 | 380в | 50-1200кг/ч | 4000Вт | 500кг | 1200*1320*1200мм | 600 мм | 920мм |

Две роликовые машины для нарезки замороженного мяса

Восемь роликовых машин для нарезки замороженного мяса

Свяжитесь с нами

В дополнение к слайсеру для замороженного мяса наша компания также предлагает широкий ассортимент машин для переработки мяса, чтобы удовлетворить различные производственные потребности.

Свяжитесь с нами для получения подробной информации и коммерческих предложений — мы поможем вам найти идеальное решение для вашего бизнеса!