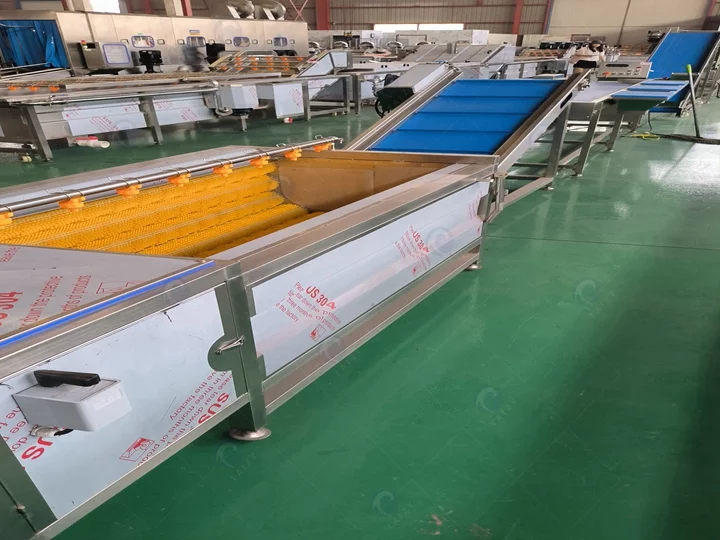

Vegetables and fruits washing and peeling machine

| Model | TZCY800 |

| Size | 1580*850*800mm |

| Power | 1.1kw |

| Weight | 180kg |

| Capacity | 800kg/h |

You can now ask our project managers for technical details

The Commercial Vegetables and Fruits Washing and Peeling Machine stands as a pinnacle of innovation in kitchen technology. This cutting-edge appliance is meticulously designed to elevate food preparation in commercial settings. By seamlessly combining the functions of washing and peeling, it not only streamlines the process but also upholds the highest standards of hygiene. Engineered for efficiency and precision, this machine is a game-changer for professional kitchens, offering a seamless solution to enhance productivity and maintain impeccable food safety protocols.

Catering to the demands of a bustling commercial kitchen, the Commercial Vegetables and Fruits Washing and Peeling Machine is a must-have for chefs and food service professionals. Its robust construction and advanced features make it ideal for those who handle large volumes of produce on a regular basis. Whether you run a high-capacity restaurant, a catering service, or a food processing facility, this machine is the cornerstone of efficiency. Embrace this technological marvel to ensure your kitchen operations are characterized by both speed and uncompromising hygiene.

Applicable raw materials for fruit and vegetable cleaning and peeling machine

Vegetables: potato, turnip, carrot, potato, onion, Chinese yam

Fruits: apple, pear, oranges, lemons, peach, apricots, dates

Nuts: walnut, chestnut

Features of vegetables and fruits cleaner and peeler machine

- Dual Functionality: This machine seamlessly combines the functions of washing and peeling, streamlining food preparation processes.

- High Capacity: Designed to handle large quantities of vegetables and fruits, making it ideal for commercial-scale operations.

- Efficient Cleaning System: Utilizes an advanced cleaning mechanism to ensure thorough and hygienic washing of produce, minimizing the risk of contaminants.

- Precision Peeling: Employs cutting-edge peeling technology to remove skin or outer layers with precision, resulting in minimal wastage.

- Adjustable Settings: Offers customizable settings to accommodate various produce sizes and types, allowing for versatility in food processing.

- Safety Features: Incorporates safety measures to prevent accidents or mishaps during operation, ensuring a secure working environment.

- Water Conservation: Incorporates water recycling systems to minimize water consumption, demonstrating an eco-conscious approach to operations.

- Durable Construction: Built with high-quality materials to withstand the rigors of commercial use, ensuring longevity and reliability.

Working principle of vegetable washing and peeling machine

The working principle of the fruit and vegetable brush cleaning machine is to use the rotation of the brush and the mutual friction between the materials to remove the soil and impurities attached to the surface of fruits and vegetables. This kind of washing machine mainly consists of a stainless steel body, brush, motor, bearing, spray pipe and electric control box and other parts.

In the operation process, the brush inside the machine will rotate with the rotation of the motor, and the surface of the fruits and vegetables to be cleaned friction, and then remove the surface dirt. At the same time, the spray pipe will spray water to further clean the fruits and vegetables, remove impurities that cannot be removed by the brush, and ensure the cleanliness of the fruits and vegetables.

Application of roller brush washing and peeling machine

- Commercial Kitchens and Restaurants: Chefs and kitchen staff in restaurants, catering services, and other food establishments that require efficient and high-capacity food preparation equipment.

- Food Processing Facilities: Professionals working in food processing plants and facilities where large quantities of fruits and vegetables need to be prepared and processed for distribution.

- Wholesale Markets and Distribution Centers: Workers involved in the sorting, cleaning, and prepping of produce for distribution to retailers, supermarkets, and other food outlets.

- Catering Services: Caterers and event planners who handle large-scale events and require rapid food preparation capabilities.

- Hotel and Hospitality Industry: Chefs and kitchen teams in hotels and hospitality establishments where efficiency and presentation are paramount.

- Food Manufacturing Units: Operators and technicians in facilities involved in the production of packaged and processed food products.

Parameters of cleaning and peeling machine

| Model | Size(mm) | Weight(kg) | Power(kw) | Capacity(kg/h) |

| TZCY800 | 1580*850*800 | 180 | 1.1 | 800 |

| TZCY1000 | 1780*850*800 | 220 | 1.5 | 1000 |

| TZCY1200 | 1980*850*800 | 240 | 1.5 | 1200 |

| TZCY1500 | 2280*850*800 | 260 | 2.2 | 1500 |

| TZCY1800 | 2580*850*800 | 280 | 2.2 | 1800 |

| TZCY2000 | 2780*850*800 | 320 | 3 | 2000 |

| TZCY2600 | 3400*850*800 | 600 | 4 | 3000 |

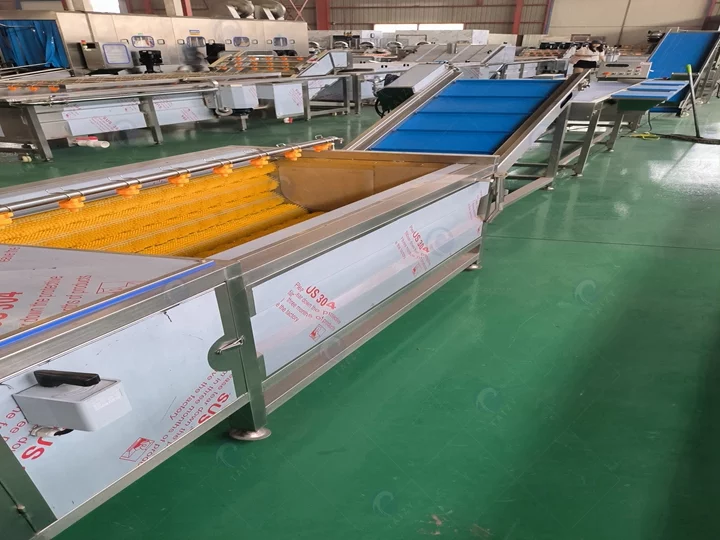

We understand that every customer’s needs are unique. For this reason, we offer a special customized service for the design of the brushes in our machines, which can be made in different sizes according to the actual needs of our customers. This unique service ensures that our products can be adapted to a wide variety of applications and cleaning needs.

In addition, we also customize our matching lifters to suit our customers’ different applications for the continuous handling of large quantities of ingredients. This comprehensive range of services is designed to meet the needs of our customers and help them achieve a smooth and efficient production process. Whether they are large-scale agricultural processing plants or catering companies, we can provide them with satisfactory products and services.