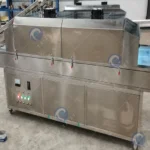

UV Sterilizer Machine | Ultraviolet Sterilization Machine

| Capacity | 200KG/H |

| Size | 2060*770*1310mm |

| Power | 600W |

| Voltage | 220V |

| Weight | 130KG |

| Full length | 2000mm(can be customized) |

You can now ask our project managers for technical details

The UV Sterilizer Machine can effectively combat and eliminate a wide range of microorganisms, including bacteria, viruses, and molds. This food sterilization machine is for high-performance, offering a sterilization rate of up to 100%, ensuring comprehensive and reliable disinfection.

We offers popular models in various sizes, including 2m, 3m, and 6m. With its versatile capacity ranging from 200 to 600 kg/h, ultraviolet sterilization machines cater to different production needs.

These models efficiently support large-scale operations and extend the shelf life of products through effective UV sterilization, contributing to improved quality and safety across various applications.

What makes UV sterilizer machines so popular?

UV sterilizer machines are highly valued for their exceptional effectiveness and versatility in sterilization. Several factors contribute to their popularity:

- High stability and longevity

These food sterilization machines boast high stability in irradiation intensity and a long sterilization life of up to 9000 hours. With a quartz glass tube that has over 87% transmittance, they efficiently deliver UV radiation. - Effective sterilization

UV sterilizers use high-frequency C-band ultraviolet radiation to disrupt the DNA of various microorganisms within 20 seconds to 1 minute. This includes harmful pathogens like influenza, hepatitis virus, and E. coli, achieving a bactericidal rate of up to 98.99%. - Durable construction

Constructed from durable 304 or 316 stainless steel with an internally polished body, these machines maximize UV irradiance for thorough disinfection.

- Enhanced performance

The inner tunnel of the machine features a high-brightness mirror sterilization reaction chamber, which increases bactericidal strength by 18%-27% compared to similar products. - User-friendly features

The UV sterilizer machine includes a sound and light alarm for lamp breakage, ensuring operational reliability. Additionally, its moderate unit price compared to similar products makes it an attractive choice for both commercial and residential use.

These attributes make UV sterilizer machines ideal for quick and effective disinfection of food, medicine, cosmetics, and various personal and public items, contributing to a safer living environment.

Applications of ultraviolet sterilization machine

- Food industry

The machine’s powerful UV radiation effectively disinfects food products, extending their shelf life and ensuring safety by eliminating harmful pathogens such as bacteria, viruses, and molds. - Medical and pharmaceutical

In healthcare and pharmaceutical settings, the UV sterilizer provides reliable disinfection for equipment, surfaces, and air, crucial for maintaining sterile environments and preventing contamination.

- Cosmetics and personal care

The machine is ideal for sterilizing cosmetic products and personal care items, ensuring they are free from microorganisms and safe for use. - Industrial applications

It efficiently handles large-scale sterilization needs in industrial environments, such as packaging and processing facilities, enhancing product safety and quality.

These applications highlight the machine’s ability to deliver thorough and reliable sterilization across diverse settings, contributing to improved safety and hygiene.

Ultraviolet sterilization machine construction and components

The UV sterilizer machine features a robust design with a 1.2mm high-quality stainless steel outer body and a 1.2mm mirror stainless steel inner cavity for the working area.

The body is supported by a Fangtong steel frame, and the air transport system includes a forced air exhaust fan to remove harmful gases.

For thermal insulation, the machine uses a double layer of vacuum aluminum silicate and silk cotton. The conveyor belt is made of Teflon mesh, and the balance device is a horizontal foot cup.

The lamp height is set at 200mm, ensuring effective and consistent UV exposure.

How does the UV sterilizer machine work?

The UV sterilizer machine uses ultraviolet (UV) radiation in the 290-400nm range. This radiation effectively eliminates microorganisms.

Unlike natural UV light, which is partially filtered by the Earth’s atmosphere, this machine emits targeted UV rays.

These rays disrupt the DNA of bacteria and viruses, preventing their reproduction and leading to their destruction.

Key points:

- Targeted UV radiation. Emits UV rays in the 290-400nm range for effective sterilization.

- DNA disruption. Specifically disrupts the DNA of microorganisms, preventing their reproduction.

- Chemical-free. Provides a thorough and sustainable sterilization method without chemicals.

Sterilization area of food sterilizer

The sterilization area of the food sterilizer is engineered for optimal, 360-degree disinfection using a highly effective ultraviolet light source. Key features include

- Comprehensive coverage. Equipped with 16 UV lamps, each 900mm long and with a 950mm effective irradiation distance, the machine ensures thorough UV coverage from all angles.

- Flexible operation. Independent control switches for each lamp allow tailored operation, enhancing efficiency and energy conservation.

- Safety and convenience. Light-shielding covers and adjustable baffles prevent UV light leakage, ensuring safe and effective sterilization.

Parameters of UV sterilizer machine

| Model | TZ-2 | TZ-3 | TZ-6 |

| Capacity | 200KG/H | 300KG/H | 600KG/H |

| Power | 600W | 800W | 600W |

| Size | 2060*770*1310mm | 3000*770*1280mm | 6000*770*1280mm |

| Weight | 130KG | 210KG | 380KG |

| Voltage | 220V | 220V | 220V |

| Full length(can be customized) | 2000mm | 3000mm | 6000mm |

| UV working area | 1200mm | 2200mm | 5200mm |

| Inlet area | 400mm | 400mm | 400mm |

| Outlet area | 400mm | 400mm | 400mm |

Conclusion

In conclusion, the UV Sterilizer Machine offers unparalleled efficiency and versatility in disinfection, making it an excellent choice for various applications, from food processing to healthcare and beyond.

For those looking to enhance their operations, consider pairing our UV Sterilizer Machine with our company’s vegetable or meat processing equipment for a comprehensive solution that maximizes both cleanliness and efficiency.

Reach out to us today to inquire about pricing and discover how our innovative technology can benefit your specific needs.