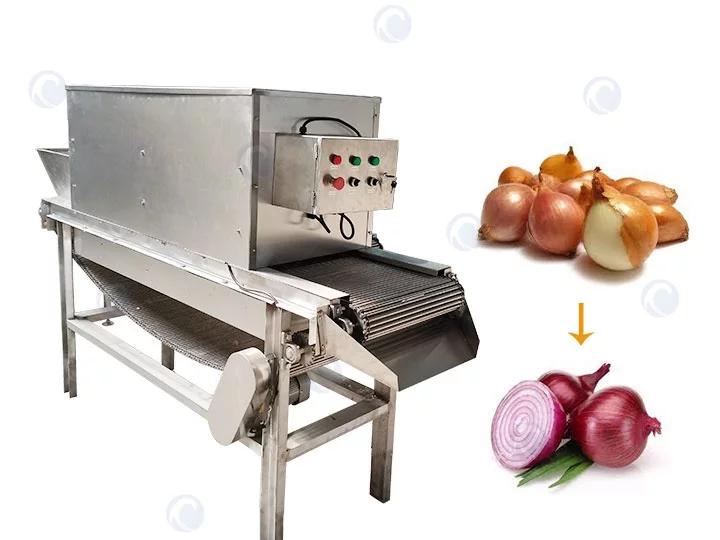

Onion peeling machine

| Model | TZ-200 |

| Power | 1.1kw |

| Voltage | 380v, 50hz |

| Capacity | 200kg/h |

| Weight | 150kg |

| Size | 1300*550*1400mm |

You can now ask our project managers for technical details

The onion peeling machine utilizes advanced high-pressure rotary airflow technology to swiftly remove the dry outer layers of onions, achieving a peeling rate of 95% or more. With a production capacity of 200 kg/h, it is designed for efficiency and ease of use. Load the onions onto the conveyor belt, and the machine handles the rest automatically.

This machine is ideal for large-scale catering enterprises, food processing plants, and frozen food factories, offering a solution that is both time-saving and labor-saving. It is also well-suited for supermarkets and wholesale markets to meet high demand, as well as agricultural cooperatives needing to process large volumes of onions efficiently.

Advantages of automatic onion peeling machine

- Preserves onion integrity. The high-pressure rotary airflow technology precisely controls air pressure and speed. It ensures that the internal structure of the onion remains intact during the peeling process.

- Efficient and fast. Utilizes high-pressure airflow to quickly and effectively remove onion skins, significantly enhancing processing speed and work efficiency.

- Durable stainless steel construction. Made from stainless steel, the machine resists corrosion from onion oils, ensuring long-lasting durability and performance.

- High automation and ease of use. The machine features high automation with automatic onion feeding and skin removal, minimizing the need for manual intervention and saving labor. It is also easy to operate and maintain with a simple, user-friendly interface.

- Versatile and hygienic. Suitable for onions of various sizes and types, the machine meets diverse processing needs. Its enclosed design facilitates easy cleaning and adheres to food safety and hygiene standards.

Working principle of the onion peeler

The onion peeler machine works by using a chain conveyor belt to precisely transport onions to the peeling area. Above this area, a high-pressure air pump generates high-pressure rotary airflow.

This airflow quickly and accurately blows away the dry skins of the onions while maintaining the integrity of the internal structure. The removed skins fall through the gaps in the conveyor belt, ensuring an efficient, precise, and damage-free peeling process.

The peeled onions are then conveyed out from the other end of the conveyor belt, ready for the next processing stage. The machine is suitable for peeling not only onions but also other similar vegetables, making it highly versatile.

The high-pressure airflow continuously peels the onions as they move, without damaging the edible parts, thus preserving the overall quality of the onions.

How to use the electric onion peeling machine?

Load the onions

Place the onions into the feed port of the machine.

Adjust air pressure

Set the air pump pressure according to the size and thickness of the onions.

Start the machine

Turn on the machine and monitor the peeling process. Make adjustments as needed to ensure optimal performance.

Onion peeler machine application

This onion peeling machine is ideal for food processing plants, restaurants, and any high-volume kitchen that requires extensive onion processing. It significantly boosts efficiency by automating the peeling process, which reduces manual labor and lowers labor costs while ensuring consistent peeling quality.

In food processing plants, this machine integrates seamlessly into production lines, enhancing overall productivity. For restaurants, it accelerates meal preparation, freeing chefs to focus on cooking rather than peeling onions.

The machine’s intuitive design and robust construction make it easy to maintain and a smart investment for any business that needs efficient onion handling. Overall, it streamlines kitchen operations, offering both increased efficiency and convenience.

Different models of the onion peeling machine

| Model | Voltage | Capacity | Weight | Size | Power |

| TZ-OP-1 | 110-220-380V | 200kg/h | 150kg | 130*55*140cm | 1.1kw |

| TZ-OP-2 | 110-220-380V | 400kg/h | 250kg | 162*55*140cm | 1.2kw |

| TZ-OP-3 | 110-220-380V | 600kg/h | 350kg | 182*60*140cm | 1.5kw |

| TZ-OP-4 | 110-220-380V | 1000kg/h | 500kg | 280*98*170cm | 3kw |

Why choose the machine of Taizy?

Taizy delivers premium onion peeling machines that are celebrated for their robustness and efficiency. Our machines are constructed from top-grade materials and subjected to strict quality checks to guarantee dependable performance.

We pride ourselves on offering exceptional after-sales support, which includes detailed training and swift technical help. Our comprehensive warranty and maintenance services further safeguard your investment.

Choosing Taizy means investing in a machine that combines durability with excellent service, ensuring a smart and efficient solution for your onion processing needs.

Contact us!

In conclusion, our onion peeling machine is an indispensable tool for anyone seeking efficiency and consistency in onion processing. Its robust design and advanced features ensure reliable performance and high-quality results.

For a complete solution, consider pairing it with our Onion Root Cutting Machine and Fruit and Vegetable Grading Machine. Together, these machines offer a seamless and streamlined processing experience, enhancing your productivity and ensuring top-notch quality in every batch.