Hamburger Patty Maker Machine

| Model | TZ-HB-400 |

| Power | 1.1kw |

| Size | 2828*830*2136mm |

| Capacity | 200-600kg/h |

| Thickness of production | 6-25mm |

You can now ask our project managers for technical details

The hamburger patty maker machine is used to create uniformly shaped and sized hamburger patties. It is typically made of aluminum or stainless steel and consists of two parts: a base and a top press. The base has a shallow indentation in the center, while the top press has a raised plunger that fits snugly into the indentation.

Hamburger patty maker machines are available in various sizes, allowing customers to select the one that produces patties of the ideal size for specific requirements. Certain models also offer extra functionalities like customizable patty thickness and patty shape.

What raw materials are suitable for hamburger patty maker machine?

The hamburger patty maker machine is highly versatile and compatible with a wide range of raw materials. It can process various types of meat such as chicken, beef, mutton, and pork. It’s also perfect for forming seafood products like fish, shrimp, squid, and salmon into uniform patties.

In addition to animal-based ingredients, this machine can handle a variety of plant-based options. Ingredients such as potatoes, sweet potatoes, pumpkins, carrots, green beans, red beans, broad beans, and soybeans can be used to make nutritious vegetable patties. For enhanced flavor and nutritional balance, these vegetables can be mixed with meat or seafood to create blended patties.

All these processed patties can be directly used in hamburger production, making the machine ideal for meat processors, fast food suppliers, and vegetarian product manufacturers.

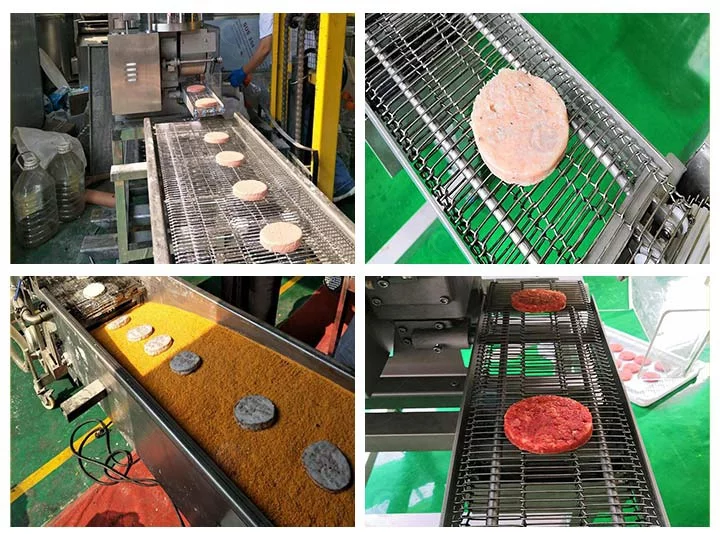

How does the hamburger patty forming machine work?

- Install the forming mold

- Attach the desired meat patty drum mold according to the required shape and size.

- Open the material barrel

- Lift the lid of the hopper to prepare for adding the meat filling.

- Install the meat pressing paddle

- Place the pressing paddle inside the barrel to help guide the meat during operation.

- Add meat filling

- Fill the barrel with the prepared meat mixture, which can include meat, seafood, or vegetable blends.

- Start the machine

- Turn on the burger patty maker to initiate the molding process.

- Meat pressing blade rotates

- The blade rotates inside the barrel, continuously pressing the meat into the forming mold.

- Forming and cutting

- The mold is filled and shaped, then a steel wire cuts the patty and moves it onto the conveyor belt.

- Continuous output

- The process repeats automatically, producing patties in a consistent and efficient cycle.

Key features of hamburger patty making machine

- Uniform patty shape & size for professional presentation.

- Adjustable thickness to meet different customer needs.

- Fast & efficient output, ideal for commercial use.

- Supports various meats & vegetables including beef, chicken, fish, and plant-based mixes.

- Stainless steel body, hygienic and easy to clean.

- Durable & safe design for long-term, worry-free operation.

Customized molds of hamburger patty maker machine

- Multiple shape options. Supports circle, triangle, rectangle, heart, and special-shaped molds.

- Brand differentiation. Custom molds help create unique product appearances for market appeal.

- Flexible applications. Suitable for meat, seafood, vegetables, or mixed fillings.

- Seamless integration. Works with meat grinder for a complete processing line.

- Ready for various processing. Formed patties can be fried, frozen, or vacuum-packed.

- Efficient production. Replaces manual labor, speeds up forming and output.

Technical parameters of burger patty machine

| Model | TZ-HB-400 |

| Size | 2828*830*2136mm |

| Capacity | 200-600kg/h |

| Weight | 100kg |

| Power | 1.1kw |

| Thickness of production | 6-25mm |

Why choose to buy our burger patty machine?

This hamburger patty maker machine combines versatility, precision, and efficiency to meet the demands of modern food production. From shape customization to streamlined operation, it empowers you to deliver consistent quality with every patty.

If you’re looking to boost productivity and enhance product appeal, this machine is a smart investment. Feel free to reach out for tailored solutions and expert support!