Fish Meat Bone Separating Machine

| Model | TZ-150 |

| Voltage | 220v |

| Power | 3kw |

| Capacity | 180kg/h |

| Weight | 180kg |

| Size | 900*680*850mm |

You can now ask our project managers for technical details

Fish Meat Bone Separating Machine is an efficient solution for separating fish flesh from bones, offering high-speed performance and excellent processing efficiency. This versatile machine is designed to process a variety of fish types, including both freshwater and saltwater species.

It utilizes a unique mechanism involving a rolling meat collecting barrel and a transmission rubber belt, effectively extracting fish meat while leaving the bones and skin behind.

Capable of processing 180 kg to 1.5 tons of fish per hour, it ensures a clean separation with a high bone removal rate of 90%, making it ideal for producing fish-based products such as fish balls in both commercial and home-use settings.

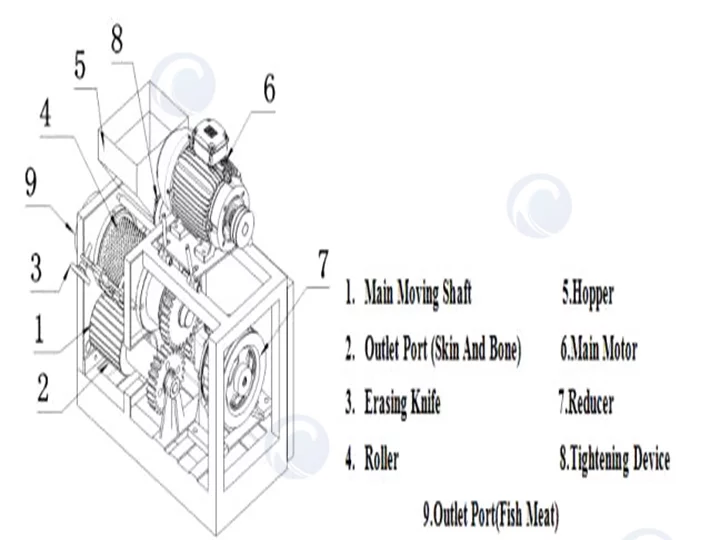

Fish meat bone separating machine structure

The Fish Meat Bone Separating Machine features a compact structure with key components designed for efficient operation:

- Motor. Drives the machine’s functions.

- Scrapers (inner and outer). Scrape fish meat from the drum’s walls and remove bones and skin.

- Tensioning and transmission devices. Ensure smooth operation and power transfer to the system.

- Conveyor belt and meat picker belt. Transport and apply pressure to separate fish meat from bones.

- Rotating drum. Varies in size by model and plays a crucial role in meat-bone separation.

- Fish bone and surimi outlets. Expel separated bones and collect processed fish meat.

- Fresh fish fillets inlet. Entry point for fish fillets.

- Automatic fine-tuning device. Adjusts pressure for consistent meat collection.

- Scraper fixed wheel. Holds the outer scraper in place.

- Gap and belt elastic adjustments. Allow fine-tuning of the meat collector belt for optimal performance.

This system ensures efficient fish meat and bone separation for various processing needs.

How does the fish meat separating machine work?

- Barrel and rubber belt mechanism. The machine uses a barrel and a rotating rubber belt to press the fish meat.

- Mutual pressing action. The fish meat is separated by the pressing force between the barrel and rubber belt, allowing the meat to stay inside the barrel.

- Bone and skin removal. Fish bones and skin are left outside the barrel, where they are scraped off by the scraper.

Key features of the fish meat bone separating machine

- Versatility. Suitable for both marine and freshwater fish, and can process large fish by segmenting them or collect meat directly from smaller fish.

- Efficient separation. Effectively separates fish bones, skin, and ribs, increasing the utilization of raw materials.

- High meat collection rate. Achieves up to 95% fish meat collection, optimizing raw material usage.

- Durability. Compact, practical, and durable design ensures long-term use.

- Economic value. Increases the economic value of low-value fish by transforming them into high-value products.

- Convenient adjustments. Features a rubber belt tensioning device to adjust pressure between the rubber belt and roller for efficient operation.

- Wide applications. Extracted fish meat can be used for various products like fish balls, fish paste, fish cakes, and more.

Supporting equipment of fish meat bone separating machine

- Meatball making machine. Ideal for shaping the extracted fish meat into uniform meatballs for further processing.

- Fish cutting machine. Prepares fish by segmenting or cutting it into suitable sizes for efficient separation.

These machines work seamlessly with the fish meat separator, enhancing processing efficiency and product quality.

Technical parameters of the fish meat bone separating machine

| Model | TZ-F150 | TZ-F200 | TZ-F300 | TZ-F350 |

| Dimension | 850*680*900mm | 900*880*950mm | 1150*870*1060mm | 1300*1000*1050mm |

| capacity | 180kg/h | 280kg/h | 360kg/h | 1.5T/h |

| Power | 2.2kw | 2.2kw | 2.2kw | 7.5kw |

| Belt thickness | 20mm | 20mm | 20mm | 20mm |

| Belt length | 1195mm | 1450mm | 1450mm | 2500mm |

| Barrel diameter | 162mm | 219mm | 219mm | 300mm |

| Barrel thickness | 8mm | 8mm | 8mm | 12mm |

| Holes diameter | 2.7mm | 2.7mm | 2.7mm(3mm) | 4/4.5/5/6mm |

| Weight | 220kg | 260kg | 320kg | 750kg |

Fish meat separating machine faqs

What types of fish can the machine process?

The machine can handle both freshwater and marine fish. It works efficiently with small fish directly and segmented larger fish.

What is the machine’s power requirement?

The machine operates on standard power and features an adjustable rubber belt tensioning device for precise processing.

What products can be made from the extracted fish meat?

The machine’s output is ideal for fish balls, fish paste, fish dumplings, shrimp balls, crab buns, and more.

How can I order or inquire further?

Feel free to contact us directly for pricing, customization options, and more information about the machine.

Conclusion

Investing in the Fish Meat Bone Separating Machine ensures efficient processing, higher raw material utilization, and the ability to produce a variety of high-value seafood products.

With its durable design and versatile applications, this machine is the ideal choice for seafood processing businesses. Contact us today to learn more about this innovative machine and get a customized quote tailored to your needs!