Spring Roll Machine | Spring Roll Making Machine

| Model | TZ-3620 |

| Size(mm) | 1800*660*890 |

| Weight | 260kg |

| Dia.of the heat roller | 400*280mm |

| Electric Power | 6kw |

| Cutting power | 1kw |

| Capacity | 800-1000pcs/h |

| Sheet max size(mm) | Only roll: 250 |

| Sheet thickness | 0.3-1.2mm |

You can now ask our project managers for technical details

The Spring Roll Machine can produce various types of sheet pasta, including spring roll wrappers, French pancakes, egg cakes, and Peking duck pancakes. It is widely used in food factories, canteens, street food vendors, and restaurants, ensuring consistency and quality in large-scale production.

With adjustable thickness options ranging from 0.3mm to 1.2mm, the Spring Roll Machine is customizable to meet specific production needs, making it an ideal choice for businesses seeking to expand their operations and profitability.

Whether you are in Europe, America, or Asia, this machine will help you meet the growing demand for spring rolls and other popular sheet pasta products.

What is spring roll?

A spring roll is a beloved dish with roots in China, known for its versatility and wide appeal. While it traditionally consists of a thin, crispy wrapper filled with a variety of savory ingredients, the concept of “spring roll” has evolved across different countries and cultures, taking on many unique forms.

In addition to the classic spring roll wrapper, you’ll encounter variations like egg cakes, roast duck cakes, pretzels, flipping buns, melaleuca cakes, injera, and even corn tortillas in different regions. These variations showcase the adaptability of the spring roll concept, often incorporating local flavors and ingredients.

Spring roll machine for sale

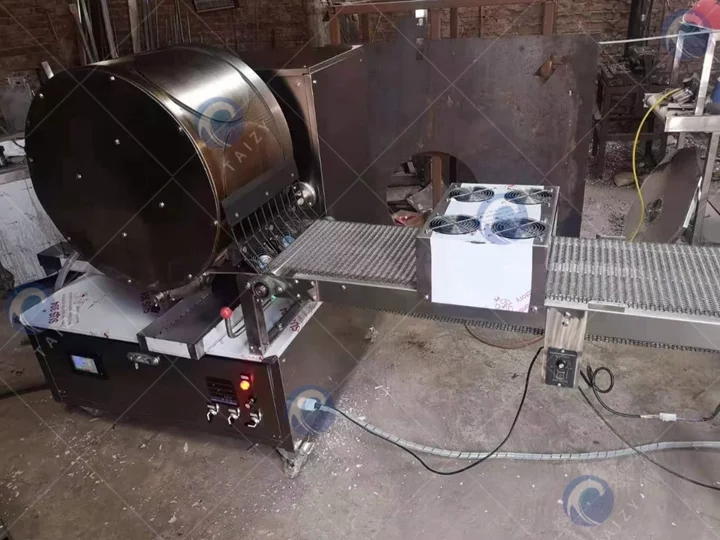

The Spring Roll Machine is a high-efficiency device designed to produce various sheet pastries like spring rolls, egg cakes, pancakes, lumpia wrappers, and crepes. It can create both round and rectangular sheets, meeting diverse product needs.

As a trusted supplier, we provide quality spring roll pastry machines, wrapping machines, and folding machines at competitive prices. Contact us today to learn more!

Spring roll making machine structure

The machine features a sturdy frame for stable operation, pneumatic-assisted pressing for uniform forming, and an electrical system for automated control.

A precise heating unit ensures consistent baking results, while adjustable temperature and time settings meet different production needs.

With customizable molds, the machine can produce products of various thicknesses and shapes, including spring roll wrappers, duck pancakes, and egg cakes.

How does the spring roll maker machine work?

- Step 1: Mixture preparation

- Pour the pre-measured flour and water mixture into the machine’s container.

- Step 2: Dough flattening

- Start the machine; the hydraulic system drives the upper mold to press the dough into thin, uniform sheets.

- Step 3: Automatic stop

- The machine stops automatically once the flattening process is completed.

- Step 4: Cooling process

- The finished sheets are moved to the cooling area, where a fan quickly cools them to achieve a crisp yet tender texture.

Performance benefits of spring roll maker

- Adjustable thickness: Customizable spring roll thickness from 0.3–1.2 mm to suit different product needs.

- Stainless steel body: Full stainless-steel construction for durability, easy operation, and low maintenance.

- Energy-saving motor: Equipped with a pure copper motor for stable performance and long service life.

- Accurate temperature control: Microcomputer-controlled heating system ensures consistent and precise temperature regulation.

- Flexible customization: Strong customization options to match different production capacities and business requirements.

Spring roll making machine parameters

| Model | TZ-3620 | TZ-5029 | TZ-8045 | TZ-12060 |

| Size(mm) | 1800*660*890 | 2400*800*1350 | 2800*1100*1600 | 3100*1300*1800 |

| Weight | 260kg | 520kg | 750kg | 850kg |

| Dia.of the heat roller | 400*280mm | 500*330mm | 800*600mm | 1200*600mm |

| Electric Power | 6kw | 13kw | 32kw | 48kw |

| Cutting power | 1kw | 1kw | 1kw | 1kw |

| Capacity | 800-1000pcs/h | 1500-2000pcs/h | 3000-4000pcs/h | 5000-6000pcs/h |

| Sheet max size(mm) | Only roll:250 | Roll:350 square:300 | Roll:430 square:450 | 600 |

| Sheet thickness | 0.3-1.2mm | 0.3-1.2mm | 0.3-1.2mm | 0.3-1.2mm |

Common spring roll machine failures and solutions

No machine will ever be error-free. So if it happens, what should we do? Here are some common spring roll making machine failures and solutions.

- If it does not run normally.

- Solution: Please turn off the power light. Then, turn on the power and make the spring roll wrapper run. If it still can’t run, please replace the inverter.

- The heating tube is not heated or intermittently heated

- Solution: Check whether the leakage control table, heating plate, and hot spot are damaged. If so, please replace them in time.

- The main engine cannot be adjusted

- Solution: Check whether the speed adjusting button is damaged, reinforce the top of the speed adjusting knob, or replace the speed adjusting button.

- Leakage circuit breaker prompt

- Solution: Check whether the heating plate is leaking and whether the connecting wire and copper slip ring is leaking. If it is leaking, we suggest replacing it.

Frequently asked questions(FAQs)

What is the shape of the finished product?

The shape can be square or round, porose or imporous.

What is the raw material put into the machine?

The raw material is flour paste, not dough.

What is the size of the finished product?

The maximum side length of the square is 30cm, the maximum diameter of the circle is 35cm, and the thickness of the pancake is generally 0.3-1.2mm.

What is the heating method?

Electric heating and gas heating.

What is the heating temperature?

120 degrees Celsius.

How to adjust the thickness?

It can be adjusted by adjusting the ratio of noodle paste, paste: water = 1:2.

What products can be manufactured?

In addition to spring roll wrapping, it can also make wonton wraps, injera, tortillas, and colorful pancakes.

Do you offer other machines?

We also offer other machines for making spring rolls. The machine for making square spring rolls has a cutter. In addition, the machine can have the function of folding and counting.

Conclusion

Spring roll machine is great food production equipment to benefit your business. Taizy Machinery Co., Ltd. is a powerful and reliable manufacturer of spring roll making machines. All our machines enjoy high performance, competitive prices, and long service life.

Besides, we provide a one-year warranty service. Whenever and whatever you have trouble with the operation or maintenance of Taizy food machines, we will let our highly skilled engineers solve it.

If you want to buy the spring roll machine online, welcome to contact us for professional buying guidance and a detailed price list.