Cocoa paste making machine

| Machine name | Cocoa bean grinding machine |

| Power | 7.5kw |

| Dimension | 750*450*1000mm |

| Capacity | 300-1200kg/h |

You can now ask our project managers for technical details

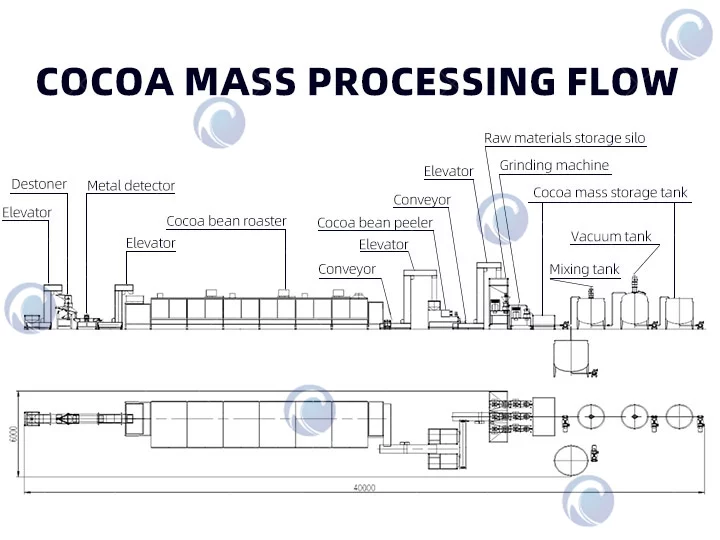

The cocoa paste making machine production line is a highly efficient cocoa processing system specially designed for cocoa paste extraction and production. Comprising a roaster, peeler, grinder, homogenizer, and storage jar, the line processes raw cocoa beans to obtain pure and delicate cocoa paste.

Cocoa paste making machine production line not only ensures stable product quality and high oil yield but also features a high degree of automation, easy operation, and strong adaptability, making it an ideal choice for cocoa mass processing in the chocolate, food, and cosmetics industries.

Cocoa paste making machine whole process

1. Cocoa bean roasting machine

The cocoa bean roasting machine is a versatile roasting equipment widely applied in the processing of cocoa beans as well as other nuts and seeds, such as peanuts, almonds, cashews, walnuts, coffee beans, and sunflower seeds. As the first step in cocoa paste production, it plays a crucial role in enhancing flavor and ensuring product quality.

This roaster is designed with a rotary drum structure that guarantees uniform heating throughout the process. It can be powered by either gas or electricity, and its stainless steel construction ensures durability and long service life. Operators can flexibly adjust both temperature and roasting time, with the maximum temperature reaching up to 300 ℃ to meet different roasting requirements.

In addition to the standard model, there are also continuous roasting machines available, some of which are integrated with cooling functions to further improve efficiency and convenience in large-scale production.

Cocoa bean roasting machine features

- The machine ensures even roasting through heat circulation via heating tubes and units, with large chain plate ovens using chain plates as conveyors.

- The cooling unit, assisted by fans, provides uniform natural airflow to effectively cool the roasted beans.

- An independent fire suppression system monitors conditions in real time and delivers timely alerts for enhanced safety.

- A Siemens PLC-controlled electrical cabinet allows precise, automated control of all roasting parameters.

2. Cocoa bean peeling machine

The cocoa bean peeling machine is specialized equipment designed to efficiently remove shells from cocoa beans. It consists of a hopper, feeding system, peeling rollers, sieve, dust collector, and fan. Once the beans enter the hopper, the rollers separate the shells, which are then removed by a centrifugal fan, leaving clean cocoa nibs to be discharged.

This machine offers high efficiency with a peeling rate exceeding 98%, operates quietly, and delivers a stable output ranging from 200 to 500 kg per hour, making it an essential component in cocoa processing lines.

Working process of cocoa bean peeling machine

- Rolling Mill Dehusking: Roasted beans pass through counter-rotating rollers that crack shells while preserving the cocoa nibs.

- Vibrating Grading Screen: Cracked beans fall onto a three-stage vibrating screen for uniform dispersion and preliminary sizing.

- Air Separation: Exhaust fans blow away lightweight shells, leaving clean cocoa nibs behind.

- Closed-Loop Recovery: Unpeeled beans are automatically returned to the feed inlet for secondary de-shelling, ensuring high efficiency and minimal waste.

3. Cocoa paste grinding machine

The cocoa paste grinding machine, commonly known as a colloid mill, is designed to transform peeled cocoa beans into smooth cocoa paste. Its grinding fineness can be adjusted according to production requirements. The machine operates through a combination of shearing, grinding, and high-speed stirring, utilizing the relative motion between a fast-spinning rotor and a stationary stator.

As the beans pass through the gap, they are subjected to intense pressure, friction, and additional forces from high-frequency vibration and vortex motion, resulting in thorough and uniform grinding. Beyond cocoa, this machine is versatile and suitable for processing various materials in the food, pharmaceutical, and chemical industries.

4. Homogenizer machine

In the cocoa paste making machine production line, the homogenizer is installed immediately after the cocoa grinder (colloid mill) to further refine the cocoa paste. It applies high shear forces to break down remaining particle clusters and evenly distribute fats, producing a smoother and more uniform cocoa paste.

This process enhances texture, stability, and overall quality, ensuring the cocoa paste meets the requirements for high-grade cocoa paste production. With adjustable pressure and flow settings, the homogenizer allows precise control over fineness, making it an indispensable component in chocolate, confectionery, and cosmetic cocoa paste processing lines.

5. Cocoa mass storage jar

The cocoa paste storage jar is an essential component in the cocoa mass production line, designed to hold and stabilize the processed cocoa paste before further use. After grinding and homogenization, the paste is directed into the storage jar, which is equipped with insulation and stirring mechanisms to maintain consistent temperature and texture.

This tank ensures the cocoa paste remains uniform and ready for subsequent production steps, while minimizing oxidation and preserving quality. It works in conjunction with mixing and vacuum tanks earlier in the process to deliver a smooth, stable, and high-quality cocoa paste base.

Cocoa paste making machine production line parameters

| Machine name | Power | Dimension | Capacity |

| Cocoa bean roasting machine | 18kw | 3000*1200*1700mm | 50-500kg/h |

| Cocoa bean peeling machine | 0.75kw | 1200*1100*1200mm | 200-500kg/h |

| Cocoa bean grinding machine | 7.5kw | 750*450*1000mm | 300-1200kg/h |

Cocoa paste making machine advantages

- Chain-plate roasters feature an intelligent fire suppression system that activates immediately when abnormal temperatures are detected.

- The cocoa bean peeling machine employs a closed-loop recycling system that recycles incompletely hulled beans, achieving up to 99% efficiency.

- The production line can be fully customized, allowing adjustment of machine configurations and output to suit specific needs.

- The system seamlessly integrates with upstream cocoa bean cleaning and grading lines and can be expanded to include cocoa powder production.

Conclusion

The cocoa paste making machine production line offers a complete solution for producing high-quality cocoa paste. Whether for chocolate, confectionery, or cosmetic applications, this production line provides reliable performance and smooth operation.

Contact us today to learn more and request a quote for a cocoa paste production solution tailored to your needs.