친친 만들기 기계

| 이름 | 친친 절단 기계 |

| 전압 | 380v, 50Hz |

| 전력 | 3kw |

| 무게 | 300kg |

| 크기 | 1060*750*1050mm |

| 용량 | 200kg/h |

| 두께 | 5-15mm |

이제 저희 프로젝트 관리자에게 기술 세부 정보를 요청할 수 있습니다

Chin chin 제조 기계 라인 또는 chin chin 생산 라인은 레스토랑, 스낵 가게, 커피 하우스 등에 적합합니다. 주로 반죽 믹서, 반죽 압착기, chin chin 절단기, chin chin 튀김기, 탈유기 및 chin chin 포장기로 구성된 6개의 기계로 이루어져 있습니다. 이 기계들은 함께 결합되어 chin chin 스낵을 자동으로 효율적으로 제조할 수 있습니다.

타이지에서 판매하는 친친 제조 기계의 생산 능력은 시간당 150kg에서 300kg까지 다양합니다. 또한 모든 기계는 식품 등급의 내구성 있는 스테인리스 강체 구조를 사용합니다. 친친 스낵 사업을 시작하려면 저희에게 연락해 주십시오.

친친 제조기의 원료

친친을 만드는 원료에는 밀가루, 설탕, 버터 또는 마가린, 계란, 우유 또는 물, 베이킹 파우더 또는 베이킹 소다, 향신료(예: 육두구 또는 계피), 소금 및 기름이 포함됩니다.

친친 생산 라인 공정

친친 생산 라인의 작업 과정은 다음과 같습니다:

반죽 혼합 → 반죽 압착 → 친친 절단 → 친친 튀김 → 친친 탈유 → 친친 포장.

타이지 친친 제조 기계 라인의 주요 기계

1. 반죽 믹서

상업적인 칭칭 생산 라인에서는 일반적으로 반죽 믹서 기계가 사용됩니다. 이 기계는 일정량의 밀가루와 물을 한 번에 혼합하여 혼합된 반죽을 얻을 수 있습니다.

혼합 기계는 믹서의 회전을 사용하여 밀가루와 물을 혼합하여 큰 혼합 반죽을 얻습니다. 전체 기계는 식품 등급 스테인리스 강 소재로 만들어졌습니다. 반죽 혼합 기계의 출력은 25kg, 50kg, 100kg 등입니다.

반죽 믹서의 매개변수

- 용량: 50kg/배치

- 시간: 3-10분

- 전압: 380v 50hz

- 전력: 3kw

- 기계 크기: 1300*730*1100mm

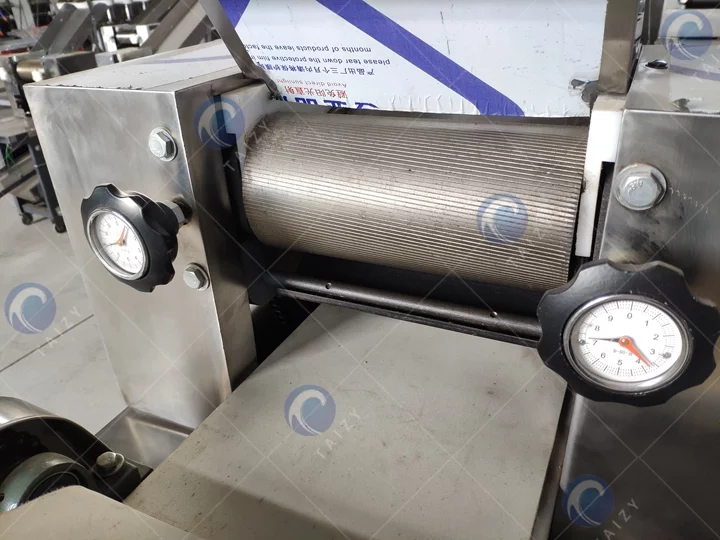

2. 반죽 압착 기계

반죽 압착 기계는 파스타 운반, 반죽, 압착 및 접기 과정을 통해 파스타를 반복적으로 압착합니다.

전통적인 수동 반죽의 복잡한 과정을 대체합니다. 노동 강도를 크게 줄이고 생산성을 향상시킵니다. 또한, 반복적으로 눌린 크러스트는 더 매끄럽고, 더 섬세하며, 더 상쾌합니다.

반죽 압착 기계 매개변수

- 전압: 380v 50Hz

- 전력: 3kw

- 무게: 200kg

- 크기: 1060*750*1050mm

- 폭 <480mm

- 두께: 5-15mm

- 용량: 200kg/h

3. 친친 절단 기계

chin chin 절단기는 반죽 시트를 작은 조각으로 압착하고 절단하는 데 사용됩니다. 완제품의 크기와 두께는 선호에 따라 맞춤 설정할 수 있습니다.

추가로, 친친 커터 기계는 절단 날을 변경하여 반죽을 정사각형, 다이아몬드, 스트립 등 다양한 형태로 자를 수 있습니다.

친친 절단 기계 기술 매개변수

- 전압: 380v, 50hz

- 전력: 2.6kw

- 용량: 150~300kg/h

- 무게: 170kg

- 크기: 1500*560*1200mm

- 폭 범위: 1.5-15mm; 다양한 폭은 커터를 변경하여 달성할 수 있습니다.

4. 친친 튀김 기계

친친 프라이어는 친친을 튀겨서 익히고 모양을 만드는 데 사용됩니다. 박스 프라이어, 원형 프라이어, 연속 메쉬 벨트 프라이어 등 다양한 친친 프라이어 옵션이 제공됩니다. 이들은 자동화 정도가 다릅니다.

반자동 친친 생산 라인은 박스형 및 원형 프라이어 중에서 선택할 수 있습니다. 연속 메쉬 벨트 프라이어는 대량 생산 수요를 위해 일반적으로 친친 가공 공장에서 사용됩니다.

친친 튀김 기계 매개변수

- 난방 출력: 12kw

- 기계 무게: 150kg

- 바구니 크기: 500*500mm

- 크기: 700*700*950mm

- 용량: 약 50 kg/h

5. 탈유 기계

튀김 후 치킨에 많은 양의 기름이 달라붙지 않도록 하여 치킨의 맛에 영향을 미치지 않도록 해야 합니다. 치킨에서 과도한 기름을 제거하기 위해 탈지 기계가 필요합니다.

탈유 기계는 일반적으로 탈유를 위해 원심 원리를 채택합니다. 탈지 시간은 타이머로 설정할 수 있으며, 알람 장치를 추가하여 알림을 받을 수 있습니다.

탈유 기계 매개변수

- 용량: 100-200kg/h

- 치수: 1100*500*850mm

- 전압: 380V, 50hz

- 전력: 1.1kw

- 무게: 150kg

6. 친친 포장 기계

Chin chin 포장 기계는 일종의 과립 파우치 포장 기계입니다. 자동으로 계량, 충전, 봉지 제작, 코딩 및 밀봉하는 기능이 있습니다.

Taizy 공장에서는 소형 수직 과립 포장 기계와 다중 헤드 계량 포장 기계의 두 가지 유형의 chin chin 포장 기계를 제공합니다. 이들은 서로 다른 기능과 이점을 가지고 있으며, 다양한 생산 요구 사항에 적합합니다.

소형 과립 포장 기계는 소규모 생산 능력에 적합하며, 다중 헤드 계량 포장 기계는 생산성이 매우 높아 대규모 생산 요구에 적합합니다.

친친 포장 기계 매개변수

- 봉투 스타일: 후면 밀봉

- 포장 속도: 32-72봉지/분 또는 100-130 봉지/분

- 봉지 길이: 30-180mm

- 봉지 너비: 25-145mm (이전 것 교체 필요)

- 충전 범위: 22-220ml

- 전력: 1.8kw

- 크기: 650*1050*1950mm

- 무게: 250kg

자동 친친 생산 라인의 특징

- 간단한 구조와 합리적인 디자인으로 조작이 용이합니다.

- 다양한 생산 요구 사항에 맞는 다양한 사양의 반자동 및 완전 자동 모델로 제공됩니다.

- 넓은 응용 범위; 다양한 커터를 변경하여 쌀국수, 꿀 세 칼 등 생산이 가능합니다.

- 균일한 형태, 균일한 절단, 좋은 형태, 반죽 낭비 없음.

- 높은 수준의 자동화로 높은 효율성을 보장합니다.

- 절단된 반죽이 달라붙지 않도록 진동 스크린이 장착되어 있습니다.

친친이 나이지리아에서 이렇게 인기 있는 이유는 무엇인가요?

친친은 서아프리카 국가, 특히 나이지리아와 가나에서 매우 인기 있는 튀긴 면 스낵입니다. 이러한 서아프리카 국가에서 친친은 파티와 여가 시간에 자주 먹는 간식입니다. 만들기 쉽기 때문에 언제 어디서나 먹을 수 있으며, 매우 맛있습니다.

그 결과, 친친의 생산과 운영은 서아프리카 국가에서 영국, 미국, 필리핀 및 기타 많은 국가와 지역으로 점차 확장되었습니다.

결론

결론적으로, 우리의 친친 제조 기계는 스낵 생산 요구에 대한 간단하고 효율적이며 다재다능한 솔루션을 제공합니다.

사용자 친화적인 디자인, 다양한 응용 프로그램, 높은 수준의 자동화 덕분에 생산 프로세스를 간소화하면서도 높은 품질 기준을 유지하려는 기업에 완벽한 선택입니다.

지금 문의하셔서 더 많은 정보와 견적 요청을 하세요!