Машина для производства чин-чин

| Имя | машина для нарезки чин-чин |

| Напряжение | 380v, 50Hz |

| Мощность | 3кВт |

| Вес | 300кг |

| Размер | 1060*750*1050мм |

| Производительность | 200кг/ч |

| Толщина | 5-15мм |

Теперь вы можете спросить наших менеджеров проектов о технических деталях

Линия для производства чин-чин или линия производства чин-чин идеально подходит для вашего ресторана, закусочных, кафе и т.д. Она в основном состоит из 6 машин: миксер для теста, машина для прессования теста, машина для нарезки чин-чин, машина для жарки чин-чин, машина для удаления масла и машина для упаковки чин-чин. Эти машины объединяются и могут автоматически и эффективно производить закуски чин-чин.

Производственная мощность машины для производства чин-чин на продажу от Taizy составляет от 150кг/ч до 300кг/ч. Кроме того, все машины используют конструкцию из нержавеющей стали, которая является пищевой и долговечной. Добро пожаловать, чтобы связаться с нами, чтобы начать свой бизнес по производству закусок чин-чин.

Сырьевые материалы для машины для производства чин-чин

Сырьевые материалы для производства чин-чин включают: муку, сахар, масло или маргарин, яйца, молоко или воду, разрыхлитель или пищевую соду, специи (такие как мускатный орех или корица), соль и масло.

Процесс линии производства чин-чин

Рабочий процесс линии производства чин-чин следующий:

Смешивание теста → прессование теста → нарезка чина чина → жарка чина чина → удаление масла чина чина → упаковка чина чина.

Основные машины линии для производства чин-чин TAIZY

1. Миксер для теста

В коммерческой линии производства чин-чин обычно используется машина для смешивания теста. Она может смешивать определенное количество муки и воды за один раз, чтобы получить смешанное тесто.

Смешивающая машина использует вращение миксера для смешивания муки и воды до получения большого смешанного теста. Вся машина изготовлена из пищевой нержавеющей стали. Выход машины для смешивания теста составляет 25кг, 50кг, 100кг и т.д.

Параметры миксера для теста

- Вместимость: 50кг/партия

- Время: 3-10мин

- Напряжение: 380в 50гц

- Мощность: 3кВт

- Размер машины: 1300*730*1100мм

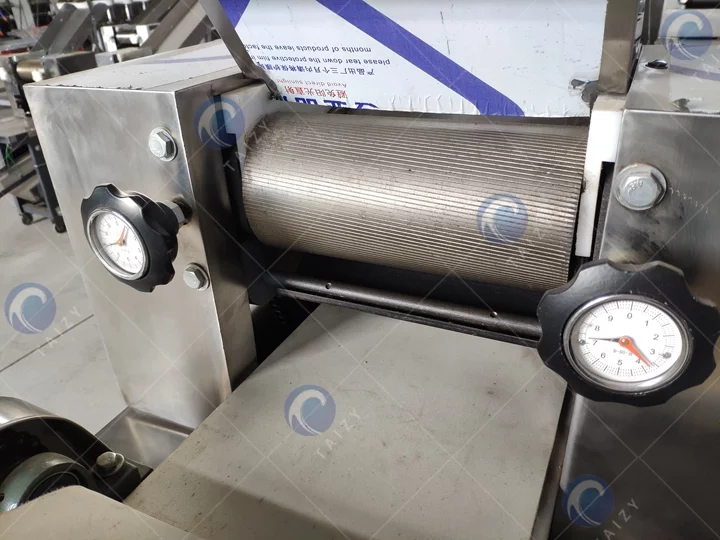

2. Машина для прессования теста

Машина для прессования теста многократно прессует пасту через процесс транспортировки пасты, замеса, прессования и складывания.

Она заменяет сложный процесс традиционного ручного замеса. Это значительно снижает трудозатраты и повышает производительность. Кроме того, многократно прессованная корка становится более гладкой, более нежной и более свежей.

Параметры машины для прессования теста

- Напряжение: 380в 50Гц

- Мощность: 3кВт

- Вес: 200кг

- Размер: 1060*750*1050мм

- Ширина <480мм

- Толщина: 5-15мм

- Производительность: 200кг/ч

3. Машина для нарезки чин-чин

Машина для нарезки чин-чин применяется для прессования и нарезки тестовых листов на маленькие кусочки. Размер и толщина готовых продуктов могут быть настроены в соответствии с предпочтениями.

Кроме того, машина для нарезки чин-чин может нарезать тесто на различные формы, такие как квадраты, ромбы и полоски, изменяя ножи для резки.

Технические параметры машины для нарезки чин-чин

- Напряжение: 380в, 50гц

- Мощность: 2.6кВт

- Производительность: 150~300кг/ч

- Вес: 170кг

- Размер: 1500*560*1200мм

- Диапазон ширины: 1.5-15мм; разные ширины можно достичь, изменяя резак.

4. Машина для жарки чин-чин

Фритюрница для чин-чин используется для жарки чин-чин, чтобы довести его до готовности и сформировать. Вам доступны различные варианты фритюрниц для чин-чин, такие как коробчатая фритюрница, круглая фритюрница и непрерывная сетчатая лента фритюрницы. У них разные степени автоматизации.

Полуавтоматическая линия по производству чин-чин может выбирать между коробчатыми и круглыми фритюрницами. Непрерывные сетчатые ленты фритюрниц обычно используются на заводах по переработке чин-чин для больших производственных потребностей.

Параметры машины для жарки чин-чин

- Тепловая мощность: 12кВт

- Вес машины: 150кг

- Размер корзины: 500*500мм

- Размер: 700*700*950мм

- Производительность: около 50 кг/ч

5. Машина для удаления масла

Чтобы избежать прилипания большого количества жира к чин-чин после жарки, что влияет на вкус чин-чин. Необходима машина для обезжиривания, чтобы удалить излишки жира из чин-чин.

Машина для обезжиривания обычно использует центробежный принцип для обезжиривания. Время обезжиривания можно установить, и можно добавить сигнализацию, чтобы напомнить.

Параметры машины для удаления масла

- Производительность: 100-200кг/ч

- Размер: 1100*500*850мм

- Напряжение: 380В, 50гц

- Мощность: 1.1кВт

- Вес: 150кг

6. Машина для упаковки чин-чин

Машина для упаковки чин-чин - это вид упаковочной машины для гранул. Она имеет функцию автоматического взвешивания, наполнения, изготовления пакетов, кодирования и запечатывания.

На фабрике Taizy мы предоставляем два разных типа машин для упаковки чин-чин: маленькие вертикальные машины для упаковки гранул и машины для упаковки с многоголовочным весом. У них разные функции и преимущества. И они подходят для различных производственных требований.

Машина для упаковки мелких гранул идеально подходит для небольших производственных мощностей, а машина для упаковки с многоhead весами имеет довольно высокую производительность и подходит для больших производственных нужд.

Параметры машины для упаковки чин-чин

- Стиль пакета: задняя запечатка

- Скорость упаковки: 32-72пакетов/мин или 100-130 пакетов/мин

- Длина пакета: 30-180мм

- Ширина пакета: 25-145мм (необходимо заменить формовщик)

- Диапазон заполнения: 22-220мл

- Мощность: 1.8кВт

- Размер: 650*1050*1950мм

- Вес: 250кг

Особенности автоматической линии производства чин-чин

- Простая структура и разумный дизайн, легкость в эксплуатации

- Доступны полуавтоматические и полностью автоматические модели с различными характеристиками, чтобы соответствовать различным производственным требованиям

- Широкий спектр применения; можно производить рисовую лапшу, медовые три ножа и т.д., изменяя различные резаки

- Однородная форма, однородная нарезка, хорошая форма и отсутствие отходов теста

- Высокий уровень автоматизации, обеспечивающий высокую эффективность

- Оснащен вибрационным экраном, чтобы предотвратить прилипание нарезанного теста

Почему чин-чин так популярен в Нигерии?

Чин-чин - это очень популярная жареная лапша-снек в странах Западной Африки, особенно в Нигерии и Гане. В этих странах Западной Африки чин-чин - это закуска, которую часто едят на вечеринках и в свободное время. Поскольку его легко приготовить, его можно есть в любое время и в любом месте, и он очень вкусный.

В результате производство и эксплуатация чин-чин постепенно расширились из стран Западной Африки в Великобританию, США, Филиппины и многие другие страны и регионы.

Заключение

В заключение, наша машина для производства чин-чин предлагает простое, эффективное и универсальное решение для ваших потребностей в производстве закусок.

С его удобным дизайном, широким спектром применения и высоким уровнем автоматизации, это идеальный выбор для бизнеса, стремящегося оптимизировать свой производственный процесс, сохраняя при этом высокие стандарты качества.

Свяжитесь с нами сейчас для получения дополнительной информации и запроса котировки!