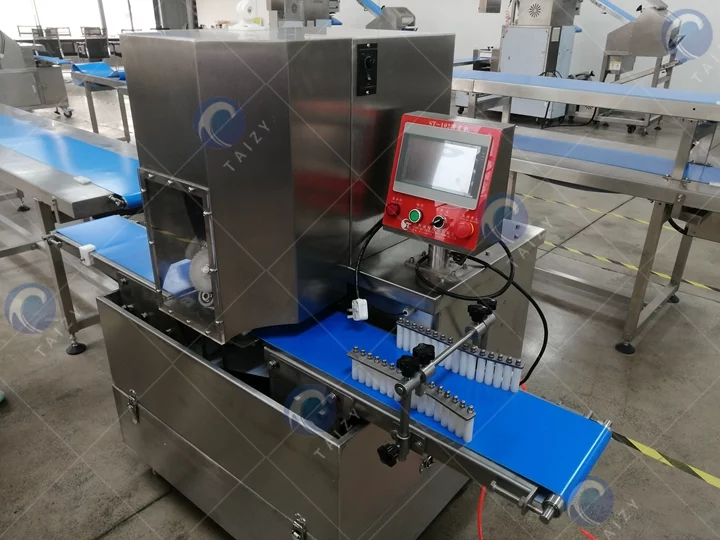

máquina de esticar massa

| Modelo | TZ-100 |

| Poder | 220v |

| Capacidade | 3000-4000 peças por hora |

| Tamanho do produto | 50-170mm |

Agora você pode pedir detalhes técnicos aos nossos gerentes de projeto

A máquina de esticar massa pode facilmente esticar massa para peles de baozi, wrappers de bolinhos e peles de wonton. Suporta um tamanho máximo de estiramento de 17 cm e oferece tamanhos personalizáveis para atender a várias necessidades de produção.

Com uma produção impressionante de 3000-4000 peças por hora, garante alta eficiência. A máquina cria massa com um centro mais grosso e bordas mais finas, proporcionando a textura perfeita para baozi, bolinhos e wrappers de wonton.

máquina de esticar massa à venda

A Máquina de Laminar Massa, com um diâmetro máximo de laminação de 17 cm, é capaz de processar massas de diferentes espessuras e tamanhos. Ela também oferece a flexibilidade de adicionar ghee, tornando-a perfeita para criar crostas folhadas e amanteigadas.

O design da máquina oferece excelente flexibilidade com diferentes opções de moldes para alcançar um centro grosso e bordas finas ou uma massa perfeitamente plana.

Características principais

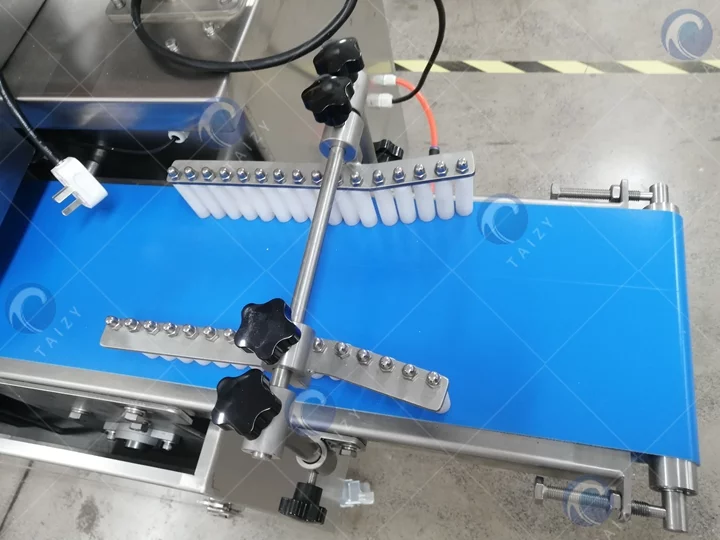

- Diâmetro máximo. 17 cm (com faixa de diâmetro de 50-170 mm), principalmente dependente da largura da correia transportadora.

- Capacidade de produção. 3000-4000 peças por hora, ou 40-60 peças por minuto, garantindo alta eficiência para produção em larga escala.

- Efeitos da massa. Opções para criar massa com um centro grosso e bordas finas ou massa perfeitamente plana com base no molde utilizado.

- Personalização. Tamanhos personalizáveis disponíveis, perfeitos para diferentes requisitos de produção.

- Operação simples. A trilha da massa é ajustada regulando o caminho da correia transportadora, garantindo um rolamento de massa suave e consistente.

- Função única. A máquina é projetada especificamente para laminar massa sem outras funções adicionais.

Equipamentos de apoio da máquina de esticar massa

A Máquina de Esticar Massa torna-se ainda mais eficiente quando emparelhada com equipamentos de apoio como a Máquina Divisora de Massa.

Essa combinação garante um processo de produção contínuo e em alta volume, não apenas laminando a massa, mas também dividindo-a com precisão em porções uniformes.

Ao usar ambas as máquinas juntas, as empresas podem aumentar significativamente a produtividade e manter a qualidade consistente da massa.

Principais benefícios de combinar a máquina de esticar massa com a máquina divisora de massa

- Porções uniformes. A Máquina Divisora de Massa garante porções de massa iguais, o que ajuda a manter a consistência no tamanho e peso do produto final.

- Aumento da eficiência. Juntas, as máquinas reduzem o trabalho manual e aceleram a produção, permitindo maior produção em menos tempo.

- Melhoria da qualidade do produto. Porções de massa consistentes e espessura uniforme levam a resultados mais consistentes em produtos como pão, pãezinhos ou bolinhos.

- Versatilidade. Essas máquinas podem ser usadas para vários tipos de massa, seja para produtos de padaria, bolinhos ou outros produtos à base de massa.

Perguntas frequentes sobre a máquina de laminar massa

Quais tipos de massa a máquina pode processar?

A máquina é adequada para uma variedade de tipos de massa, incluindo massa para bolinhos, baozi, wrappers de wonton e outros produtos à base de massa. Pode ser usada tanto para massa macia quanto firme.

A espessura da folha de massa pode ser ajustada?

Sim, a espessura da folha de massa pode ser facilmente ajustada usando as configurações da máquina. Isso permite a personalização da espessura da massa para atender a diferentes aplicações, como peles mais grossas para baozi ou folhas mais finas para bolinhos.

Como a Máquina de Laminar Massa consegue o efeito de ‘centro mais grosso e bordas mais finas’?

A máquina usa moldes especialmente projetados para criar folhas de massa com um centro mais grosso e bordas mais finas, o que é ideal para certos tipos de bolinhos, tortas e outros produtos.

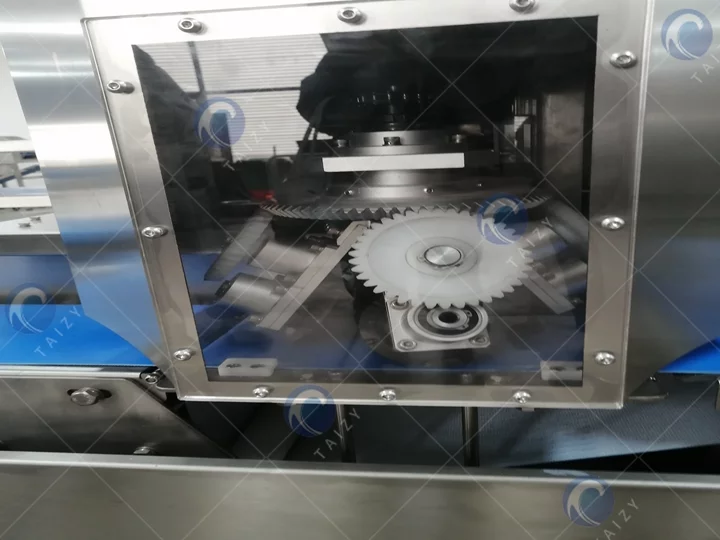

A máquina é fácil de limpar e manter?

Sim, a Máquina de Laminar Massa é projetada para fácil manutenção. Os componentes são facilmente acessíveis para limpeza, garantindo que você possa manter os padrões de higiene e prolongar a vida útil da máquina.

Caso de sucesso da massa rolador

Uma empresa de alimentos, com sede nos Estados Unidos, se especializa na produção de baozi e bolinhos, mas enfrentou problemas com espessura desigual da massa e baixa eficiência de produção. Eles estavam procurando uma laminadora de massa de alta eficiência para garantir qualidade consistente da massa.

Após entender as necessidades do cliente, recomendamos a Máquina de Laminar Massa, que permite ajuste preciso da espessura da massa, adequada para produção em larga escala. Abordamos as preocupações do cliente em relação à produção e facilidade de operação

Após a implementação, esta empresa de alimentos aumentou a produção, com qualidade consistente da massa. A eficiência de produção melhorou em 30%, e o cliente ficou muito satisfeito com o desempenho da máquina e os resultados da massa.

Conclusão

Em conclusão, a Máquina de Laminar Massa é uma ferramenta essencial para empresas que buscam melhorar a eficiência do processamento de massa enquanto mantêm resultados de alta qualidade. Com sua capacidade de produzir espessura de massa consistente e lidar com produção em alta volume, é perfeita para padarias, restaurantes e fabricantes de alimentos.

Para mais informações ou para consultar preços, sinta-se à vontade para entrar em contato conosco. Estamos felizes em ajudá-lo com quaisquer perguntas e fornecer uma solução adaptada às necessidades do seu negócio.