Tortilla Maker Machine|Taco Making Machine

| Model | TZ-350 |

| Size | 2050*600mm |

| Voltage | 380v |

| Weight | 100KG |

| Power | 5KW |

| Capacity | 400 sheets/hour |

You can now ask our project managers for technical details

In the bustling world of culinary innovation, one household appliance stands out for its fusion of traditional cuisine and modern convenience—the Tortilla Maker Machine, also known as the Corn Tortilla Machine.

Rooted in centuries-old culinary traditions, this ingenious device has completely transformed the way corn tortillas are made, turning what was once a laborious and time-consuming process into one that is efficient and consistent.

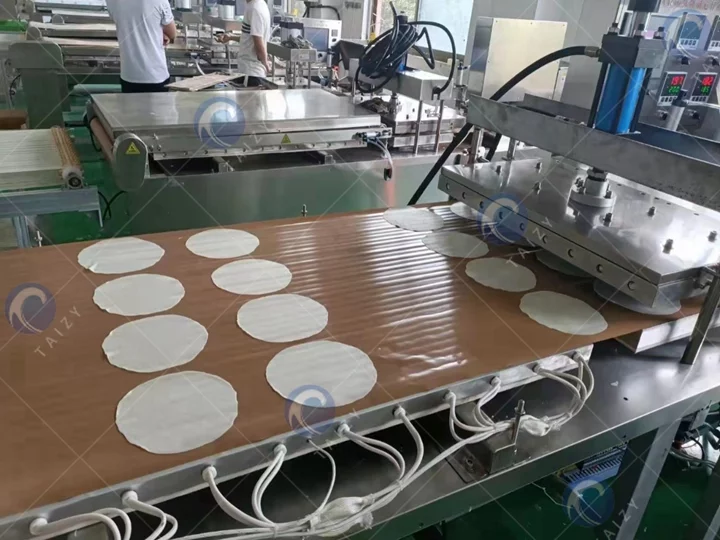

The Tortilla Maker Machine employs precision engineering and ergonomic design to seamlessly transform raw masa dough into perfectly round, thin tortillas. Whether you prefer the warmth of freshly made corn tortillas or the versatility of wheat tortillas, this machine effortlessly caters to various tastes and preferences.

Key features of the Taco Maker Machine

The Tortilla Maker Machine boasts several key features that set it apart as a versatile and efficient appliance for producing delicious tortillas.

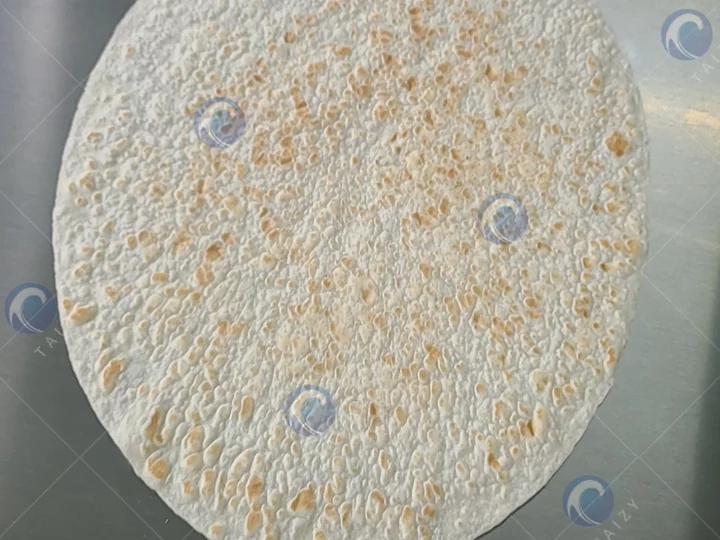

Firstly, its heating method utilizes electric heating, ensuring consistent and precise temperature control throughout the tortilla-making process. This allows for uniform cooking and browning, resulting in perfectly cooked tortillas every time.

Furthermore, the machine offers adjustable thickness settings, allowing for the production of tortillas with thickness ranging from 0.5mm to 3mm. This versatility enables users to customize the thickness of their tortillas according to their preferences or specific culinary requirements.

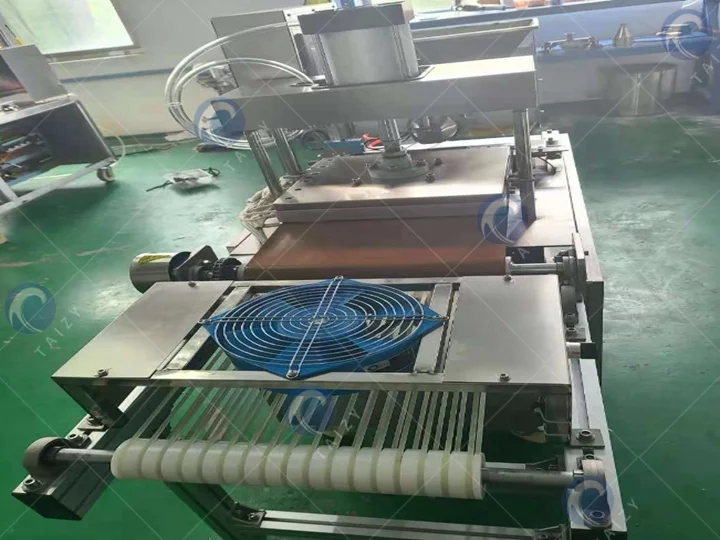

In addition, the Tortilla Maker Machine is equipped with a pneumatic system, enhancing its operational efficiency and performance. This pneumatic system facilitates smooth and reliable operation, ensuring consistent production output while minimizing downtime.

How does the Tortilla Making Machine work?

The Tortilla Making Machine operates by using a motor to drive various types of dough through an extrusion device at a steady speed, resulting in uniform output. Subsequently, the cylindrical dough is cut and shaped by a cutting mechanism.

Following this, the dough undergoes pre-pressing and shaping with upper and lower pressing plates before entering upper and lower baking trays for baking. After baking, the tortillas then proceed through a cooling process with the aid of airflow and are dusted with flour.

Additionally, the machine is equipped with an upper flouring mechanism, where a motor and brush work together to evenly distribute flour onto the tortillas. This feature not only ensures uniform flour coverage on the product surface but also effectively prevents sticking, particularly for dough with high viscosity.

Moreover, the lower discharge orifice can be adjusted to control the amount of flour dispensed, catering to specific product requirements. The precise operation and coordination of these processes ensure efficient production and consistent quality and texture of the tortillas produced by the Tortilla Making Machine.

What foods can be made with the Tortilla Maker Machine?

The versatility of the Tortilla Maker Machine extends far beyond its name, as it is adept at crafting an array of delectable dishes. Primarily designed for making chapati pancakes, tortillas, roti, and peking duck pancakes, this industrial marvel proves to be a culinary powerhouse capable of much more.

Its adaptable design and precision engineering enable the creation of various flatbreads and pancakes, each with its own unique texture and flavor profile.

From the soft and pillowy texture of chapati pancakes to the thin and flexible nature of tortillas, the Tortilla Maker Machine ensures consistency and quality in every batch. Whether it’s unleavened flatbreads or savory pancakes, this machine effortlessly caters to a diverse range of culinary preferences and cultural traditions.

Moreover, its ability to handle a variety of dough types and thicknesses allows for endless creativity in the kitchen. From traditional recipes to innovative culinary creations, the Tortilla Maker Machine empowers chefs and food enthusiasts alike to explore new horizons in gastronomy.

With its reliability and precision, this machine becomes an indispensable asset in any commercial kitchen or food production facility, elevating the art of flatbread and pancake making to new heights.

Supporting equipment of the taco making machine

Our Taco Making Machine is designed to seamlessly integrate with essential supporting equipment, including dough mixers and packaging machines.

Dough mixers play a pivotal role in the initial stages of taco production, ensuring the uniform mixing of ingredients to create the perfect masa dough. This consistency guarantees the high-quality foundation necessary for crafting delicious tacos efficiently.

Meanwhile, packaging machines complement the Taco Making Machine by efficiently wrapping each taco with precision and speed. This ensures the preservation of freshness and hygiene, making the tacos ready for distribution or display with ease.

Together, these supporting equipment components streamline the taco-making process, enabling culinary professionals to deliver consistently exceptional tacos to eager customers.

Technical parameters of the Tortilla Maker Machine

| Model | TZ-350 | TZ-450 | TZ-650 |

| Size | 2050*600mm | 5200*800*1400 | 5200*1000*1400 |

| Voltage | 380v | 380v | 380v |

| Weight | 100kg | 440kg | 500kg |

| Power | 5kw | 15kw | 18kw |

| Capacity | 400 sheets/hour | 700 sheets/hour | 1400 sheets/hour |

Maintenance of the Taco Making Machine

To keep the Taco Making Machine running smoothly, follow these maintenance guidelines:

- Clean disassembled parts with warm water or neutral detergent after daily production.

- Avoid washing the machine body with running water.

- Use caution when handling parts to prevent damage.

- Always switch off the power before disassembling the machine.

- Thoroughly clean residues on high-temperature belts and wipe dry with a clean cloth.

- Lubricate drive components once per shift using lubricating oil after ensuring the main power supply is switched off.

By adhering to these simple maintenance practices, you can ensure the efficient performance and longevity of your Taco Making Machine.

Conclusion

In Taizy Machinery, we not only offer powerful and efficient Tortilla Maker Machines but also strive to provide outstanding product experiences and comprehensive after-sales services to our customers.

Our machines are manufactured using advanced technology and precise craftsmanship, ensuring stable and reliable performance for every unit.

Moreover, we have a highly experienced and professionally skilled team capable of providing personalized customization services and timely technical support to our customers.

Whether you are seeking solutions to enhance production efficiency or aiming to further develop your food processing business, we can provide the best-suited solutions for you. If you are interested in our Tortilla Maker Machine or have any inquiries, please feel free to contact us.

We are committed to serving you wholeheartedly and providing you with detailed product information and quotations. We look forward to collaborating with you and jointly ushering in a new era of delicious food processing!