Cashew Shelling Machine

| Brand | Taizy |

| Capacity | 40kg/h; 50kg/h; 80kg/h; 100kg/h; 200kg/h |

| Function | Cashew nut shell removing |

| Note | Customization service is available |

You can now ask our project managers for technical details

Cashew shelling machine is a durable and efficient tool designed to quickly remove the shells from cashews with precision. With a powerful motor that can shell up to 200 kg of cashews per hour, it’s perfect for company in the cashew industry looking to streamline their production process and increase output.

The automatic cashew nut shelling machine has a very high shelling ratio of 98% and no damage to the cashew. With rich experience in the industry of nuts processing, our nut machines have been successfully exported to more than 30 countries and regions. If you are interested in this machine, with not hesitate to contact us for a free and best price list.

Features/ benefits of cashew nut shelling machine

- The cashew shelling machine for sale is designed with several key features that make it stand out from manual shelling methods. For one, the machine is incredibly efficient, capable of shelling up to 200 kg of cashews per hour. This speed is unmatched by manual methods, which can be slow and labor-intensive.

- Additionally, the machine is designed to remove the shells from cashews with precision and accuracy, ensuring that the nut itself is not damaged in the process. This is important because damaged nuts can lead to lower quality products, which can have a negative impact on sales and profits.

- Another key feature of the cashew nut shell removing machine is its durability. The machine is built to last, with sturdy construction that can withstand heavy use over time. This means that businesses can rely on the machine to perform consistently day after day, without worrying about frequent repairs or replacement.

- The benefits of using the cashew nut sheller are numerous. For one, the machine can significantly increase production output, allowing businesses to process more cashews in less time. This, in turn, can lead to increased sales and profits.

- Additionally, the machine can help improve the quality of the final product. By removing shells with precision and accuracy, the machine helps ensure that each nut is of high quality and undamaged. This can lead to higher customer satisfaction and repeat business.

- Finally, the automatic cashew shelling machine can also help reduce labor costs. With manual shelling methods, businesses need to hire and pay workers to shell cashews by hand. With the machine, however, businesses can automate the process, reducing the need for manual labor and potentially saving money in the long run.

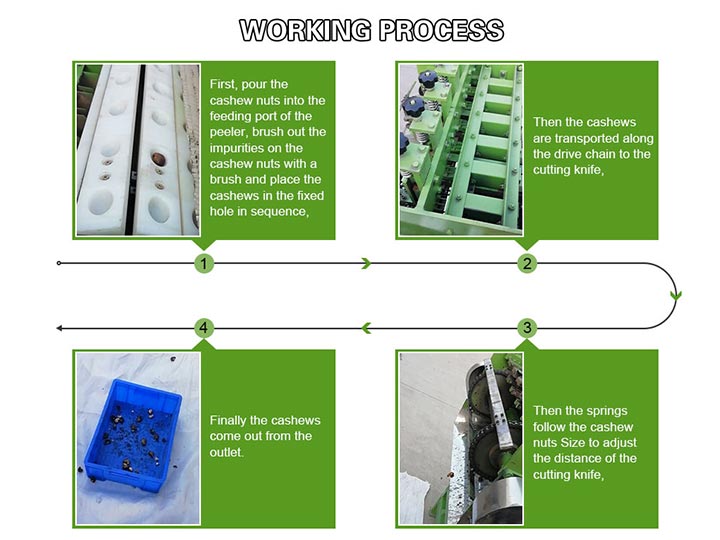

How does the cashew nut shelling machine work?

The Cashew Shelling Machine works by using a series of blades and rollers to crack open the shells of cashews. The machine is designed to be easy to use, with a simple interface that allows operators to adjust the machine’s settings and monitor its progress.

To use the machine, operators first load cashews into the hopper. The machine then uses its blades and rollers to crack open the shells, while a vacuum system removes the shells and separates them from the nuts. The nuts are then collected in a separate container, ready for further processing or packaging.

It’s important to note that proper usage and maintenance of the Cashew Shelling Machine is essential to ensure its longevity and efficiency. This includes regularly cleaning the machine and its components, checking for and addressing any issues, and following the manufacturer’s instructions for use.

Applications of cashew sheller machine for sale

Cashew processing: A machine is an essential tool in the cashew industry, allowing businesses to process cashews quickly and efficiently.

Food manufacturing: The machine can be used in food manufacturing to shell nuts for use in a variety of products, such as baked goods, snacks, and confectionery items.

Agriculture: The machine can be used in agriculture to shell other types of nuts, such as almonds, pistachios, and hazelnuts.

Research and development: The machine can also be used in research and development settings to test and refine nut shelling processes.

Maintenance and care of cashew shelling machine

Proper maintenance and care of the Cashew Shelling Machine are important to ensure its longevity and efficiency. Here are some tips for maintaining and caring for the machine:

- Clean the machine and its components regularly, using a soft cloth and mild detergent.

- Check for and address any issues, such as damage to the blades or rollers.

- Lubricate the machine’s moving parts as recommended by the manufacturer.

- Store the machine in a dry, cool place when not in use.

- Follow the manufacturer’s instructions for use and maintenance.

Common issues that can arise with the Cashew Shelling Machine include blade and roller damage, blockages in the vacuum system, and motor issues. It’s important to address these issues promptly to prevent further damage and ensure the machine continues to operate efficiently.

Contact us to start your business!

The cashew shelling machine is a highly efficient and durable tool that is essential to the cashew industry and beyond. With its ability to quickly and accurately remove cashew shells, the machine can significantly increase production output, improve product quality, and reduce labor costs.

The automatic cashew nut shelling machine is quite a popular product from Taizy factory. And cashew has huge business value. If you want to start your cashew processing project. With no hesitation in reaching out for more machine details and the best price.