Machine de fabrication de menton

| Nom | machine de découpe de menton |

| Tension | 380v, 50Hz |

| Pouvoir | 3kw |

| Poids | 300 kg |

| Taille | 1060*750*1050mm |

| Capacité | 200kg/h |

| Épaisseur | 5-15mm |

Vous pouvez désormais demander des détails techniques à nos chefs de projets

La ligne de fabrication de Chin Chin ou la ligne de production de Chin Chin est idéale pour votre restaurant, vos magasins de collations, vos cafés, etc. Elle se compose principalement de 6 machines : mélangeur de pâte, machine à presser la pâte, machine à découper Chin Chin, machine à frire Chin Chin, machine à dégraisser et machine à emballer Chin Chin. Ces machines s'assemblent et peuvent fabriquer des collations de Chin Chin automatiquement et efficacement.

La capacité de production de la machine à faire chin chin à vendre chez Taizy varie de 150 kg/h à 300 kg/h. De plus, toutes les machines utilisent une structure en acier inoxydable, qui est un matériau de qualité alimentaire et durable. N'hésitez pas à nous contacter pour commencer votre entreprise de snacks chin chin.

Matières premières de la machine à Chin Chin

Les matières premières pour faire chin chin comprennent : farine, sucre, beurre ou margarine, œufs, lait ou eau, levure chimique ou bicarbonate de soude, épices (comme la muscade ou la cannelle), sel et huile.

Processus de la ligne de production de menton

Le processus de travail de la ligne de production de chin chin est le suivant :

Mélange de pâte → pressage de la pâte → coupe du menton → friture du menton → déshuilage du menton → emballage du menton.

Principales machines de la ligne de machines de fabrication de menton TAIZY

1. Mélangeur de pâte

Dans une ligne de production commerciale de chin chin, une machine à mélanger la pâte est généralement utilisée. Elle peut mélanger une certaine quantité de farine et d'eau à la fois pour obtenir une pâte mélangée.

La machine de mélange utilise la rotation du mélangeur pour mélanger la farine et l'eau jusqu'à obtenir une grande pâte mélangée. L'ensemble de la machine est fabriqué en acier inoxydable de qualité alimentaire. La sortie de la machine à mélanger la pâte est de 25 kg, 50 kg, 100 kg, etc.

Paramètres du mélangeur de pâte

- Capacité : 50 kg/batch

- Temps : 3-10 min

- Tension : 380 V 50 Hz

- Puissance : 3kw

- Taille de la machine : 1300*730*1100 mm

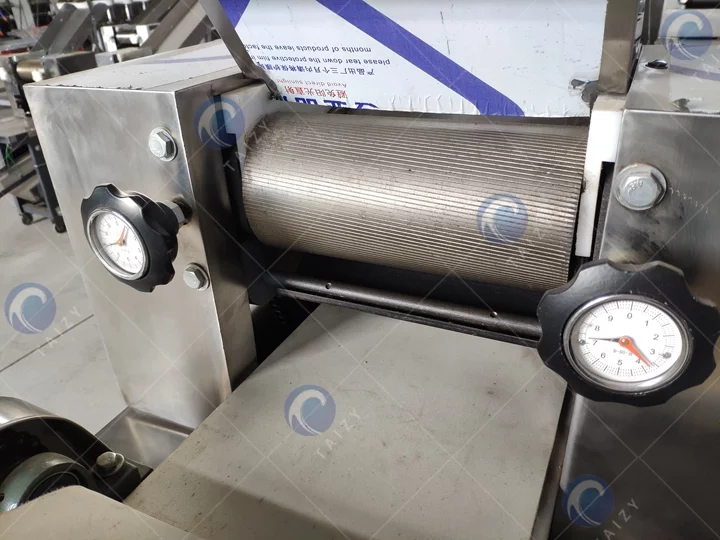

2. Machine à presser la pâte

La machine à presser la pâte presser la pâte à plusieurs reprises à travers le processus de transport de la pâte, de pétrissage, de pressage et de pliage.

Elle remplace le processus compliqué du pétrissage manuel traditionnel. Elle réduit considérablement l'intensité du travail et améliore la productivité. De plus, la croûte pressée à plusieurs reprises est plus lisse, plus délicate et plus rafraîchissante.

Paramètres de la machine à presser la pâte

- Tension : 380 V 50 Hz

- Puissance : 3kw

- Poids : 200 kg

- Taille : 1060*750*1050 mm

- Largeur < 480 mm

- Épaisseur : 5-15 mm

- Capacité : 200 kg/h

3. Machine à découper Chin Chin

La machine à couper chin chin est utilisée pour presser et couper des feuilles de pâte en petits morceaux. La taille et l'épaisseur des produits finis peuvent être personnalisées selon les préférences.

De plus, la machine à couper chin chin peut couper la pâte en différentes formes telles que des carrés, des losanges et des bandes en changeant les lames de coupe.

Paramètres techniques de la machine à couper chin chin

- Tension : 380 V, 50 Hz

- Puissance : 2,6 kW

- Capacité : 150~300 kg/h

- Poids : 170 kg

- Taille : 1500*560*1200 mm

- Plage de largeur : 1,5-15 mm ; différentes largeurs, vous pouvez les obtenir en changeant le coupeur.

4. Machine à frire chin chin

La friteuse chin chin est utilisée pour frire chin chin afin de le cuire et de lui donner sa forme. Une grande variété d'options de friteuses chin chin est disponible, telles que friteuse à boîte, friteuse circulaire et friteuse à bande maillée continue. Elles ont différents degrés d'automatisation.

La ligne de production chin chin semi-automatique peut choisir entre des friteuses de type boîte et de type rond. Les friteuses à bande maillée continue sont généralement utilisées dans les usines de transformation chin chin pour une demande de production importante.

Paramètres de la machine à frire chin chin

- Puissance de chauffage : 12 kW

- Poids de la machine : 150 kg

- Taille du panier : 500*500 mm

- Taille : 700*700*950 mm

- Capacité : environ 50 kg/h

5. Machine à dégraisser

Pour éviter qu'une grande quantité de graisse ne colle au chin chin après la friture, ce qui affecte le goût du chin chin. Il faut une machine à dégraisser pour enlever l'excès de graisse du chin chin.

La machine à dégraisser adopte généralement le principe centrifuge pour dégraisser. Le temps de dégraissage peut être chronométré et un dispositif d'alarme peut être ajouté pour rappeler.

Paramètres de la machine à dégraisser

- Capacité : 100-200 kg/h

- Dimension : 1100*500*850 mm

- Tension : 380 V, 50 Hz

- Puissance : 1,1 kW

- Poids : 150 kg

6. Machine à emballer chin chin

La machine à emballer chin chin est un type de machine à emballer en sachets de granulés. Elle a la fonction de peser automatiquement, de remplir, de fabriquer des sacs, de coder et de sceller.

Dans l'usine Taizy, nous proposons deux types différents de machines à emballer chin chin, des machines à emballer granulés verticales petites et des machines à emballer à peseur multi-têtes. Elles ont différentes caractéristiques et avantages. Et elles conviennent à différentes exigences de production.

La petite machine d'emballage de granulés est idéale pour une petite capacité de production, et la machine d'emballage à peseur multi-têtes a une productivité assez élevée et convient aux besoins de production importants.

Paramètres de la machine à emballer chin chin

- Style de sac : scellé à l'arrière

- Vitesse d'emballage : 32-72 sacs/min ou 100-130 sacs/min

- Longueur du sac : 30-180 mm

- Largeur du sac : 25-145 mm (nécessite de remplacer le formateur)

- Plage de remplissage : 22-220 ml

- Puissance : 1,8 kW

- Taille : 650*1050*1950 mm

- Poids : 250 kg

Caractéristiques de la ligne de production automatique de menton

- Structure simple et conception raisonnable, facile à utiliser

- Disponible en modèles semi-automatiques et entièrement automatiques avec différentes spécifications pour répondre à diverses exigences de production

- Large gamme d'applications ; peut produire des nouilles de riz, des trois couteaux au miel, etc., en changeant de différents coupeurs

- Forme uniforme, découpe uniforme, bonne forme et pas de gaspillage de pâte

- Niveau élevé d'automatisation, garantissant une haute efficacité

- Équipé d'un tamis vibrant pour empêcher la pâte découpée de coller

Pourquoi le menton menton est-il si populaire au Nigeria ?

Le Chin Chin est un en-cas de nouilles frites très populaire dans les pays d'Afrique de l'Ouest, en particulier au Nigeria et au Ghana. Dans ces pays d'Afrique de l'Ouest, le Chin Chin est un en-cas souvent consommé lors des fêtes et pendant les moments de loisirs. Parce qu'il est facile à préparer, il peut être mangé à tout moment et n'importe où, et il est très savoureux.

En conséquence, la production et l'exploitation du Chin Chin se sont progressivement étendues des pays d'Afrique de l'Ouest au Royaume-Uni, aux États-Unis, aux Philippines et dans de nombreux autres pays et régions.

Conclusion

En conclusion, notre machine à Chin Chin offre une solution simple, efficace et polyvalente pour vos besoins de production de snacks.

Avec son design convivial, sa large gamme d'applications et son haut niveau d'automatisation, c'est le choix parfait pour les entreprises cherchant à rationaliser leur processus de production tout en maintenant des normes de qualité élevées.

Contactez-nous maintenant pour plus d'informations et pour demander un devis !