Máquina de prensado de aceite

| Modelo | 6YZ-180 |

| Capacidad | 30kg/h |

| Peso | 750 kilos |

| Tamaño | 500*650*1050mm |

| Fuerza | 2kw |

| Presión | 55Mpa |

Ahora puede solicitar detalles técnicos a nuestros jefes de proyecto

La máquina de prensado de aceite puede separar eficientemente el aceite de varias semillas y nueces. Se utiliza ampliamente para procesar cacahuetes, soja, colza, sésamo, nueces, cocos y otros materiales crudos que contienen aceite.

Para satisfacer las diversas necesidades de diferentes usuarios y entornos de producción, nuestra empresa ofrece una amplia gama de máquinas de prensado de aceite. Proporcionamos cuatro modelos principales: la Máquina de Prensado de Aceite Semiautomática, la Máquina de Prensado de Aceite de Doble Temperatura, la Máquina de Prensado de Aceite de Tornillo y la Máquina de Prensado de Aceite Hidráulica.

A diferencia de los métodos de extracción química, este proceso mecánico ayuda a retener los nutrientes naturales, el aroma y el sabor del aceite, convirtiéndolo en una opción preferida tanto para productores comerciales como para usuarios conscientes de la salud.

Máquina de prensado de aceite semiautomática

Nuestra máquina de prensado de aceite semiautomática es una solución robusta y adaptable diseñada para productores de aceite de pequeña a mediana escala que buscan eficiencia con automatización manejable.

Diseñada para manejar una amplia gama de materiales que contienen aceite, este modelo procesa eficientemente cultivos populares como cacahuetes, semillas de sésamo, colza (canola) y otras semillas oleaginosas similares.

Ofrece un rendimiento constante donde el rendimiento final del aceite depende intrínsecamente de la calidad y el contenido de aceite inherente del material de entrada.

Key features & operation

- Core mechanism. Utilizes a powerful screw rotation system to apply continuous, high pressure for effective oil extraction.

- Power flexibility. Offers exceptional operational versatility by being compatible with both electric motors and diesel engines, making it suitable for locations with varying power infrastructure.

- Output characteristic. The extraction process efficiently separates oil, but the pressed cake may contain more residual impurities, requiring further filtration.

- Unique value-add function. A key advantage is its ability for secondary pressing, allowing hot oil cake to be repressed for higher oil yield and reduced waste.

Positioning & target users

Esta máquina de prensado de aceite semiautomática logra un equilibrio óptimo entre asequibilidad, simplicidad operativa y versatilidad.

It’s an excellent choice for farmers, homesteaders, and small commercial oil mills looking for a dependable, cost-effective entry into oil production or requiring a flexible machine capable of handling multiple seed types without complex setup.

Parámetros de la máquina

| Modelo | Capacidad(t/24h) | Velocidad de rotación(rpm) | Potencia (kilovatios) | Tamaño (mm) | Peso (kg) |

| 6YL-68 | 0.8-1 | 30-40 | 5.5 | 880*440*770 | 160 |

| 6YL-80 | 2-3 | 30-40 | 5.5 | 1510*440*770 | 360 |

| 6YL-95 | 3.5-4 | 30-40 | 7.5 | 1640*640*1200 | 460 |

| 6YL-100 | 3-5 | 30-40 | 7.5 | 1640*640*1200 | 480 |

| 6YL-120 | 4-6 | 30-40 | 11 | 1760*640*1300 | 600 |

| 6YL-130 | 9-12 | 30-40 | 15-18.5 | 1950*680*1490 | 800 |

| 6YL-165 | 15-20 | 28-38 | 22-30 | 2300*850*1560 | 1100 |

Máquina de extracción de aceite de doble temperatura

La máquina de extracción de aceite de doble temperatura, también conocida como la máquina de prensado de aceite de tornillo caliente y frío totalmente automática, está diseñada para prensar tanto materias primas frías como materiales tostados calientes.

Es adecuada para extraer una amplia gama de aceites como aceite de sésamo, aceite de semilla de girasol, aceite de cacahuete, aceite de colza, aceite de ricino, aceite de semilla de algodón, aceite de soja, aceite de nuez, aceite de almendra, aceite de piñón, aceite de linaza y aceite de alfalfa.

Key advantages

- Amplia adaptabilidad de materiales

- Unlike conventional presses, this machine allows hot pressing of sunflower seeds, peanuts, castor seeds, and cotton seeds without pre-shelling or roasting, reducing equipment costs and simplifying the process.

- Preserva la nutrición y la calidad

- El prensado en frío retiene mejor los nutrientes naturales en las semillas oleaginosas.

- El aceite prensado en frío es más puro y tiene un color más brillante.

- Genera poco humo durante la cocción y es reconocido como más saludable.

- Automatización y eficiencia

- Equipped with an automatic screw conveyor, significantly saving labor.

- Features an oil residue recycling system to reuse residue and improve oil yield.

- Filtración integrada

- Includes dual vacuum filters, directly filtering the pressed oil without needing an extra oil filter machine.

Especificaciones técnicas

| Modelo | ZY-125 | ZY-150 |

| Potencia del motor principal | 15 kW | 37 kW |

| Potencia de la bomba de vacío | 1.5 kW | 2.2 kW |

| Capacidad de procesamiento | 150-200 kg/h | 300-350 kg/h |

| Peso de la máquina | 986 kg | 2500 kg |

| Dimensiones (LxWxH) | 1900x1100x1500 mm | 2100x1300x1700 mm |

Máquina de prensa de aceite de tornillo

La máquina de prensado de aceite de tornillo es un modelo de prensado en caliente totalmente automático, ideal para operaciones comerciales de extracción de aceite que requieren alta eficiencia y salida constante.

Esta máquina combina control de temperatura inteligente, alta presión y filtración eficiente para ofrecer un rendimiento y calidad de aceite superiores.

Características clave

- Hot pressing with preheating. Equipped with an electric heating ring, the machine can preheat before operation, ensuring optimal temperature for efficient oil extraction.

- Internal screw structure. A continuous screw shaft compresses and squeezes oil from seeds, increasing output and reducing residue.

- Vacuum oil filter barrel. Comes with a built-in vacuum filter to quickly purify the extracted oil, removing impurities and improving clarity.

- Electric motor driven. This model is powered solely by electricity, providing stable and quiet operation—ideal for modern workshops or processing plants.

- Replaceable pressing bars. The internal pressing bars are considered consumables and are easy to replace, making long-term maintenance simple and cost-effective.

- High oil yield. Due to the strong pressing force and heated process, this machine delivers a higher oil yield compared to semi-automatic or cold-press models.

Parámetros de la máquina

| Modelo | 6YL-60 | 6YL-70 | 6YL-100 | 6YL-125 |

| Diámetro del tornillo (mm) | Φ55 | Φ65 | Φ100 | Φ125 |

| Velocidad de rotación del tornillo (r/min) | 64 | 38 | 37 | 34 |

| Potencia principal (kw) | 2.2 | 3 | 7.5 | 15 |

| Potencia de la bomba de vacío (kw) | 0.75 | 0.75 | 0.75 | 0.75 |

| Potencia de calefacción (kw) | 0.9 | 1.8 | 3 | 3.75 |

| Capacidad (kg/h) | 40-60 | 50-70 | 150-230 | 300-350 |

| Peso (kg) | 240 | 280 | 1100 | 1400 |

| Tamaño (mm) | 1280*880*1220 | 1400*900*1260 | 1900*1200*1300 | 2100*1300*1700 |

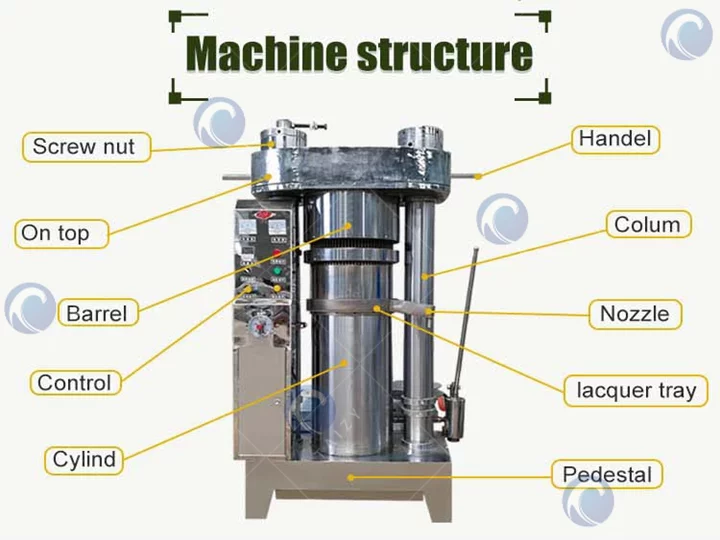

Hydraulic oil making machine

La máquina de fabricación de aceite hidráulico es un equipo especializado de prensado en frío diseñado para extraer aceite de materias primas con alto contenido de aceite.

A diferencia de los modelos de tipo tornillo, esta máquina opera con un potente cilindro hidráulico, aplicando presión vertical a través de un Mecanismo de prensado hacia arriba y hacia abajo, asegurando una liberación de aceite lenta, constante y eficiente sin generar calor excesivo.

Esta máquina es especialmente adecuada para la producción de aceite premium, donde preservar los nutrientes, el aroma y el sabor es esencial.

Características clave

- Hydraulic system. Utilizes a built-in hydraulic oil cylinder to deliver strong, uniform pressure, ideal for delicate oilseeds.

- No internal screw. The absence of a screw shaft ensures a cleaner pressing process with minimal residue and no mechanical grinding.

- Vertical pressing motion. Oil is extracted through presión hidráulica ascendente y descendente, haciendo que el proceso sea silencioso, eficiente y fácil de controlar.

- Perfecto para materiales especiales. Adecuado para materiales con alto contenido de aceite como:

- Sésamo

- Aguacate

- Nuez

- Coco (la cáscara debe ser retirada y la pulpa pre-triturada)

- Ventajas del prensado en frío: Mantiene el sabor original y el perfil nutricional del aceite, ideal para mercados preocupados por la salud.

Con su estructura simple, bajo ruido y excelente calidad de aceite producido, la máquina de hacer aceite hidráulica es una opción preferida para productores de aceite boutique, laboratorios o negocios enfocados en la extracción de aceite comestible de alto valor en pequeñas cantidades.

Estructura de la máquina de prensado de aceite

Parámetros de la máquina

| Modelo | 6YZ-180 | 6YZ-230 | 6YZ-260 | 6YZ-320 |

| Diámetro de alimentación | 180mm | 230mm | 260mm | 320mm |

| Diámetro del pastel de aceite | 180mm | 230mm | 260mm | 320 mm |

| Fuerza | 2kw | 2kw | 2kw | 2kw |

| Presión | 55Mpa | 55Mpa | 55Mpa | 55Mpa |

| Tiempo de prensado | 7min | 8min | 10min | 10Min |

| Capacidad (por vez) | 2-3kg | 7–8kg | 10-12kg | 15kg |

| Capacidad | 30kg/h | 50kg/h | 60kg/h | 90kg/h |

| Dimensión (mm) | 500*650*1050 | 600*850*1360 | 650*900*1450 | 800*1100*1550 |

| Peso | 750kg | 1050kg | 1400kg | 2000kg |

Equipos de apoyo de la máquina de prensado de aceite

La máquina de trituración juega un papel crucial en la optimización del proceso general de extracción de aceite, especialmente al tratar con materias primas duras o fibrosas. Por ejemplo, al procesar cocos, es esencial primero quitar la cáscara y triturar la carne de coco en partículas finas para asegurar un prensado de aceite suave y eficiente.

Para satisfacer esta necesidad, ofrecemos máquinas de trituración de alto rendimiento como un dispositivo de apoyo clave para nuestras líneas de prensado de aceite. Estos trituradores están diseñados para manejar materiales como pulpa de coco, hueso de palma y otras semillas oleaginosas duras, mejorando significativamente la eficiencia del prensado y protegiendo la prensa de aceite principal de bloqueos o alimentación desigual.

Al integrar nuestra máquina de trituración con la máquina de prensado de aceite, los usuarios pueden lograr:

- Mejor rendimiento de aceite a través de una preparación de material más fina

- Menor desgaste mecánico en la prensa debido a una alimentación uniforme

- Mayor velocidad de procesamiento y mejora de la eficiencia general de producción

Conclusión

En resumen, nuestras máquinas de prensado de aceite—que van desde modelos semiautomáticos hasta de tornillo, de doble temperatura y hidráulicos—ofrecen soluciones flexibles para diversas necesidades de producción y materias primas.

Si está buscando comenzar o expandir su producción de aceite comestible, no dude en contactarnos para recomendaciones personalizadas y un presupuesto competitivo.