বোবা পিয়ারল মেকার মেশিন

| মডেল | TZ-1000 |

| আকার | 1350*900*850mm |

| ওজন | 220kg |

| ক্ষমতা | ৮০-৯০কেজি/ঘণ্টা |

| শক্তি | 0.55kw |

| ভোল্টেজ | ২২০ভি/৩৮০ভি |

আপনি এখন আমাদের প্রকল্প ব্যবস্থাপকদের কাছ থেকে প্রযুক্তিগত বিস্তারিত জানতে পারেন

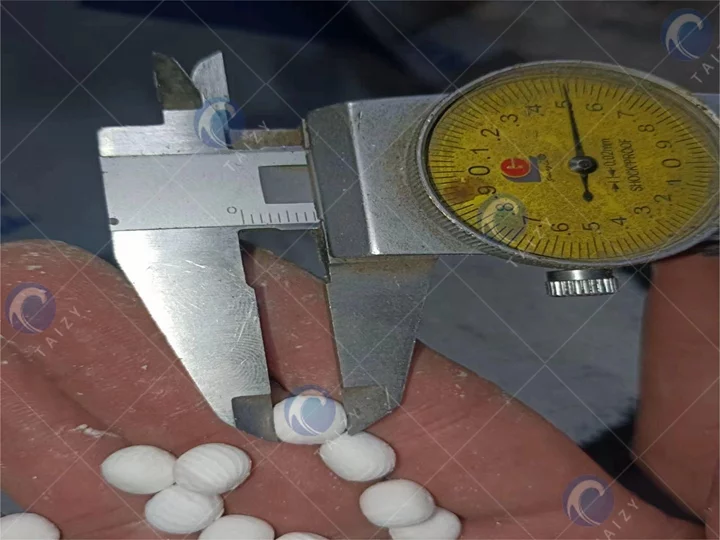

বোবা পার্ল মেকার মেশিন ট্যাপিওকা ডোকে নিখুঁত গোলাকার পার্লে রূপান্তর এবং কাটার প্রক্রিয়াটি স্বয়ংক্রিয় করে, যা সমান আকার এবং ধারাবাহিক গুণমান নিশ্চিত করে। এটি 2 মিমি থেকে 10 মিমি ব্যাসের পার্ল উৎপাদন করতে পারে, বিভিন্ন পানীয় শৈলীর জন্য উপযুক্ত।

প্রতি ঘণ্টায় 120 কিলোগ্রাম পর্যন্ত উৎপাদন ক্ষমতা নিয়ে, এটি কার্যকারিতা উল্লেখযোগ্যভাবে বাড়ায় এবং পানীয় শিল্পে অভূতপূর্ব সুবিধা এবং গুণমান নিশ্চিতকরণ নিয়ে আসে।

বোবা পার্ল কিভাবে তৈরি করবেন?

ডো প্রস্তুত করুন

- মোটা চালের আটা প্রধান উপাদান হিসেবে ব্যবহার করুন।

- গরম পানির সাথে গ্লুটিনাস রাইস ফ্লাওয়ার ভালোভাবে মিশিয়ে একটি ডো মিক্সারে মিশ্রণ করুন যতক্ষণ না এটি ভালোভাবে মিশে যায়।

চালের আটা প্রক্রিয়া করুন

- প্রথমে, চালের ময়দা ৮০-৯০% রান্না হওয়া পর্যন্ত স্টিম করুন।

- ভাপানো চালের আটা মিক্সারে স্থানান্তর করুন।

ভিজা এবং শুকনো আটা একত্রিত করুন

- ভিজা চালের আটা মিক্সারে যোগ করুন।

- একই সময়ে, শুকনো চালের ময়দা যোগ করুন।

- মিশ্রণটি ভালোভাবে মিশিয়ে নিন যতক্ষণ না এটি সমান এবং সঙ্গতিপূর্ণ হয়।

চূড়ান্ত আকার দেওয়া

- মিশ্রিত ময়দাকে আবার একটি সমতল স্কয়ার আকারে চাপুন।

- আকৃতির ময়দা বাণিজ্যিক বাবা মেকার মেশিনের ফিডার হপার এ রাখুন।

বোবা পার্ল মেকার মেশিন কিভাবে কাজ করে?

- কনিষ্ঠ ট্যাপিওকা স্টার্চের ময়দা মেশিনের ফিড পোর্টে রাখা হয়।

- একটি ডো রোলার ময়দাকে সমান পুরুত্বের একটি শীটে চাপ দেয়।

- ময়দার শীট একটি ফর্মিং মোল্ডে প্রবেশ করে যার ছোট ছিদ্রগুলি পিয়ারলের আকার এবং আকৃতি নির্ধারণ করে।

- মোল্ডের নিচে একটি কাটার ময়দাকে ছোট পিলেটে কেটে দেয়।

- রোলিং ডিভাইসটি তখন পেলের উপর ঘূর্ণন করে এবং ঘর্ষণের মাধ্যমে গোলাকার টাপিওকা পার্লে পরিণত করে।

বাবা মেকার মেশিনের মূল বৈশিষ্ট্য এবং সুবিধাসমূহ

- বড়া পার্ল তৈরি করে যা আকারে সমান, ধারাবাহিক গুণমান নিশ্চিত করে।

- মিষ্টি পিঠা ভাঙার সম্ভাবনা কমায়, সম্পূর্ণ পণ্য নিশ্চিত করে।

- চালানো এবং পরিষ্কার করা সহজ, ডাউনটাইম এবং রক্ষণাবেক্ষণের প্রচেষ্টা কমায়।

- বিভিন্ন রঙের বড়া উৎপাদন সমর্থন করে যাতে বৈচিত্র্যময় বাজারের চাহিদা পূরণ হয়।

- স্বয়ংক্রিয় প্রক্রিয়া জীবাণুমুক্তি বাড়ায়, দূষণের ঝুঁকি কমায়, খাদ্য নিরাপত্তা এবং উচ্চমানের আউটপুট নিশ্চিত করে।

বাবা মেকার মেশিনের ব্যবহার

বোবা মেকার মেশিনটি দক্ষতার সাথে ট্যাপিওকা পার্ল তৈরি করে, যা মিশ্রণ, এক্সট্রুডিং এবং আটা গঠন করে সমান গোলক তৈরি করে। এটি নির্দিষ্ট উৎপাদন প্রয়োজন অনুযায়ী বিভিন্ন আকার এবং রঙের পার্ল তৈরি করতে পারে।

এটি বিভিন্ন ধরনের স্টার্চ-ভিত্তিক ডো প্রক্রিয়া করতে পারে, যা কেবল ক্লাসিক ট্যাপিওকা পার্লস নয় বরং অন্যান্য অনুরূপ স্ন্যাক পণ্য উৎপাদনের সক্ষমতা প্রদান করে। স্বয়ংক্রিয় এবং স্বাস্থ্যকর কার্যক্রমের সাথে, মেশিনটি ধারাবাহিক গুণমান এবং উচ্চ আউটপুট নিশ্চিত করে, যা ধারাবাহিক বাণিজ্যিক উৎপাদনের জন্য উপযুক্ত।

রক্ষণাবেক্ষণ বোবা মুক্তা তৈরির মেশিনের

বোবা পার্ল মেকার মেশিন পরিষ্কার এবং রক্ষণাবেক্ষণ করা দীর্ঘমেয়াদী, নির্ভরযোগ্য অপারেশন এবং স্বাস্থ্যবিধি নিশ্চিত করার জন্য অত্যন্ত গুরুত্বপূর্ণ। এখানে কিছু সুপারিশ রয়েছে:

- কোনও পরিষ্কার করার আগে সর্বদা পাওয়ার বন্ধ করুন যাতে অপারেটরের নিরাপত্তা নিশ্চিত হয়।

- গভীর পরিষ্কারের জন্য মিশ্রণ চেম্বার এবং টেমপ্লেটের মতো সমস্ত অপসারণযোগ্য অংশ বিচ্ছিন্ন করুন।

- সব উপাদান থেকে যেকোনো আটা অবশিষ্টাংশ মুছতে একটি নরম ব্রাশ বা ভিজা কাপড় ব্যবহার করুন।

- গোলাকার পার্লের আকার এবং আকৃতি বজায় রাখতে টেমপ্লেটের ছিদ্রগুলি সাবধানে পরিষ্কার করুন।

- নিয়মিতভাবে রাবার বা সিলিকন সীলের ক্ষতি পরীক্ষা করুন এবং লিক প্রতিরোধের জন্য প্রয়োজন হলে সেগুলি প্রতিস্থাপন করুন।

- গতি অংশগুলি মসৃণভাবে কাজ করতে রাখতে নিয়মিত খাবার গ্রেড লুব্রিকেটিং তেল বা গ্রিজ প্রয়োগ করুন।

- নিয়মিতভাবে তার, প্লাগ এবং বৈদ্যুতিক উপাদানগুলির ক্ষতি বা পরিধানের কোনও চিহ্ন পরীক্ষা করুন।

- পারফরম্যান্সে ধুলো বা ময়লা প্রভাবিত হওয়া প্রতিরোধ করতে নিয়ন্ত্রণ প্যানেল এবং বৈদ্যুতিক অংশগুলি পরিষ্কার করুন।

বাবা পিয়ারল মেকার মেশিনের প্রযুক্তিগত প্যারামিটার

| মডেল | আকার (মিমি) | পাওয়ার(kW) | ভোল্টেজ(ভি) | ক্ষমতা(কেজি/ঘণ্টা) | ব্যাস (মিমি) |

| TZ-1000 | 1300*950*1100 | 0.55 | 220/380 | 80-90 | 8-25 |

| TZ-1200 | 850*900*1300 | 0.7 | 220/380 | 90-120 | 6-22 |

উপসংহার

উৎপাদন দক্ষতা আরও বাড়ানোর জন্য, বোবা পিয়ারল মেকার মেশিনকে আমাদের ময়দা মিশ্রক এবং ময়দা বিভাজক এর সাথে নিখুঁতভাবে যুক্ত করা যেতে পারে, সম্পূর্ণ স্ট্রিমলাইন প্রক্রিয়ার জন্য—ময়দা প্রস্তুতি থেকে চূড়ান্ত আকার দেওয়া পর্যন্ত.

বিস্তারিত স্পেসিফিকেশন এবং মূল্য তালিকার জন্য আমাদের সাথে যোগাযোগ করতে বিনা দ্বিধায়—আমরা আপনার প্রয়োজনের জন্য কাস্টমাইজড সমাধান প্রদান করতে এখানে আছি!