Máquina fabricante de pérolas Boba

| Modelo | TZ-1000 |

| Tamanho | 1350*900*850mm |

| Peso | 220kg |

| Capacidade | 80-90kg/h |

| Poder | 0,55 kW |

| Tensão | 220v/380v |

Agora você pode pedir detalhes técnicos aos nossos gerentes de projeto

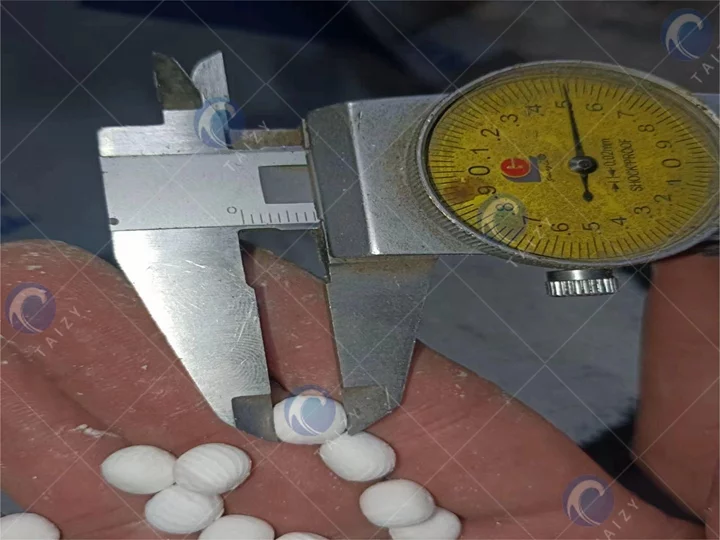

The Boba Pearl Maker Machine automates the process of shaping and cutting tapioca dough into perfectly round pearls, ensuring uniform size and consistent quality. It can produce pearls ranging from 2mm to 10mm in diameter, catering to various beverage styles.

With a production capacity of up to 120 kilograms per hour, it significantly boosts efficiency and brings unprecedented convenience and quality assurance to the beverage industry.

How to make boba pearls?

Prepare the dough

- Use glutinous rice flour as the main ingredient.

- Mix glutinous rice flour with boiling water thoroughly in a dough mixer until well combined.

Process the rice flour

- First, steam the rice flour until it is 80–90% cooked.

- Transfer the steamed rice flour into the mixer.

Combine wet and dry flour

- Add the wet rice flour into the mixer.

- Simultaneously, add the dry rice flour.

- Mix thoroughly until the mixture is even and consistent.

Final shaping

- Press the combined mixture into a flat square shape again.

- Place the shaped dough into the feeder hopper of the commercial boba maker machine.

How does the boba pearl maker machine work?

- The kneaded tapioca starch dough is placed into the machine’s feed port.

- A dough roller presses the dough into a sheet with uniform thickness.

- The dough sheet enters a forming mold with small holes that define the pearl’s size and shape.

- A cutter beneath the mold slices the dough into small pellets.

- The rolling device then rolls and polishes the pellets into round tapioca pearls through friction.

Principais recursos e vantagens da máquina boba maker

- Produces boba pearls that are uniform in size for consistent quality.

- Minimizes breakage of sweet dumplings, ensuring intact finished products.

- Easy to operate and clean, reducing downtime and maintenance effort.

- Supports production of boba in various colors to meet diverse market demands.

- Automated process enhances hygiene by reducing contamination risks, ensuring food safety and high-quality output.

Aplicações da máquina boba maker

The boba maker machine efficiently produces tapioca pearls by mixing, extruding, and shaping dough into uniform spheres. It can create pearls of various sizes and colors according to specific production needs.

It can also process different types of starch-based dough, enabling the production of not only classic tapioca pearls but also other similar snack products. With automated and hygienic operation, the machine ensures consistent quality and high output, suitable for continuous commercial production.

Maintenance of the boba pearl maker machine

A limpeza e a manutenção da máquina Boba Pearl Maker são cruciais para garantir sua operação e higiene confiáveis e de longo prazo. Aqui estão algumas recomendações:

- Always turn off the power before starting any cleaning to ensure operator safety.

- Disassemble all removable parts like the mixing chamber and template for thorough cleaning.

- Use a soft brush or damp cloth to remove any dough residues from all components.

- Carefully clean the holes in the template to maintain uniform pearl size and shape.

- Regularly inspect rubber or silicone seals for damage and replace them as needed to prevent leaks.

- Regularly apply food-grade lubricating oil or grease to keep moving parts operating smoothly.

- Frequently inspect wires, plugs, and electrical components for any signs of damage or wear.

- Clean the control panel and electrical parts to prevent dust or dirt from affecting performance.

Technical parameters of the boba pearl maker machine

| Modelo | Tamanho (mm) | Potência (kW) | Tensão (v) | Capacidade (kg/h) | Diameter(mm) |

| TZ-1000 | 1300*950*1100 | 0.55 | 220/380 | 80-90 | 8-25 |

| TZ-1200 | 850*900*1300 | 0.7 | 220/380 | 90-120 | 6-22 |

Conclusão

To further improve production efficiency, the Boba Pearl Maker Machine can be perfectly paired with our misturador de massa e divisor de massa for a fully streamlined process—from dough preparation to final shaping.

Feel free to contact us for detailed specifications and pricing—we’re here to provide customized solutions for your needs!