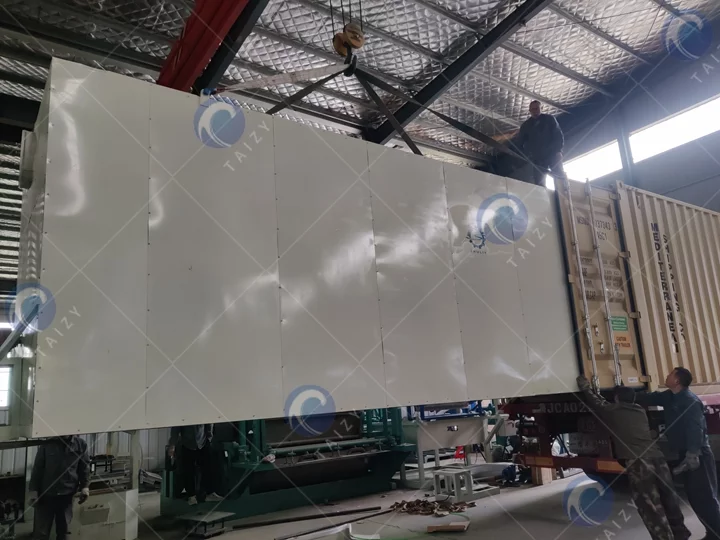

Industrial french fries production line sent to the UK

In October 2025, our company supplied a complete 50 kg/h industrial French Fries Production Line to a UK-based food processing business.

The customer is a growing crisp-and-snack manufacturer located near Manchester, specialising in premium potato snacks for both retail and food-service markets.

Customer background

The client is a family-owned snack company founded in 2012, which originally focused on kettle-fried chips. Over time, they identified a strong demand in the UK and EU markets for high-quality frozen French fries made from locally sourced potatoes.

With contracts starting to roll in from major retailers and quick-service restaurants, their existing equipment (single fryers and bagging lines) could no longer keep up with demand. They required a reliable, fully automated production line that could handle the washing, peeling, slicing, blanching, frying, deoiling, flavouring and packaging of frozen fries.

Challenges our customer face

- Their previous setup could only process ~10 kg/h of cut potato sticks, causing significant bottlenecks as orders increased.

- Frequent quality inconsistencies: uneven slice size, poor blanching, high oil retention, and unstable flavouring resulted in rejected batches.

- Limited space in their existing facility required a compact footprint system.

- UK-market requirements: strict food-safety regulations (Hygiene Regulation, CE compliance), and demand for traceability and automation.

Our solution

We customized a 50 kg/h industrial French fries production line featuring:

- Full processing steps: potato washing & peeling → slicing → blanching → dewatering → frying → deoiling → flavouring → automatic packaging.

- Food-grade stainless steel (304) construction, cleaning in place (CIP) friendly, full compliance with UK/EU standards.

- Compact layout to fit within the customer’s existing floor plan; modular design allows future expansion to 100 kg/h or 200 kg/h capacity.

- Turn-key service including installation, commissioning, staff training, and remote support post-delivery.

Industrial french fries production line benefits

- Production capacity increased from ~10 kg/h to 50 kg/h, enabling the customer to fulfil new contracts and reduce lead time.

- Quality improvements: thanks to uniform slicing, efficient blanching and oil removal, finished fries achieved consistent colour and texture, and oil content dropped by ~20%.

- Flexible product offering: the line supports multiple potato-based raw materials (regular potato, sweet potato, cassava), allowing the customer to diversify their snack portfolio.

- Operational efficiency: automation reduced labour hours by approximately 30 % and simplified cleaning and maintenance routines.

Feedback from the client

“This production line has transformed our business. We now fulfil retailer orders reliably, with a consistent premium product for frozen fries. The installation went smoothly and your team has been there every step of the way. We’d absolutely recommend your solutions to other snack processors.” – UK SnackCo (Manchester region)

Summary

If you’re looking to upgrade your snack or potato-processing facility, or expand into frozen French fries production, we invite you to contact us for a detailed quotation.

Our production lines are tailor-made, fully automated, and built for international standards — easily configurable to satisfy your capacity, product finish, and ROI targets.