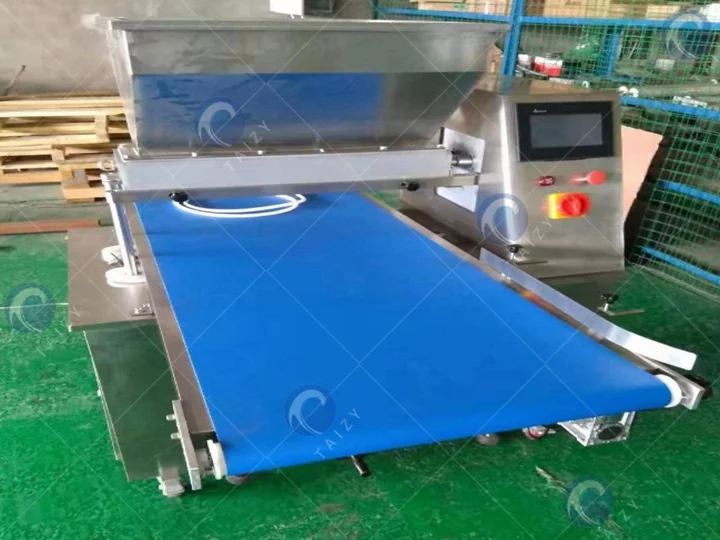

Commercial cake filling machine exported to the UK

Early this month, our TZ-600 Commercial Cake Filling Machine was shipped to the UK to support bakeries in improving production efficiency and ensuring consistent product quality.

Customer background

Our customer has a bakery in the UK, specializing in high-end cakes and desserts, decided to invest in a high-efficiency, reliable Commercial Cake Filling Machine. The goal was to improve production efficiency and ensure consistent product quality amid growing orders.

Equipment selection

After careful evaluation, the bakery selected the TZ-600 Commercial Cake Filling Machine. Key technical parameters and features include:

- Model: TZ-600

- Size: 1.7 × 1.1 × 1.4 m

- Capacity: 120–240 kg/h

- Power: 1.2 kW

- Weight: 380 kg

- Construction: Full stainless steel, food-grade, easy to clean

- Control system: User-friendly interface for precise control of filling volume and speed

- Versatility: Quick-change nozzles for various cake shapes and filling types

- Automation: Automated filling system ensures accurate portioning and reduces human error

- Additional features: Optional mini oil sprayer prevents sticking and ensures smooth operation

Positive feedback of using our cupcake filler

Since installing the TZ-600 Commercial Cake Filling Machine, the bakery has experienced significant improvements:

- Increased production efficiency: The machine processes 120–240 kg/h, boosting production speed and meeting growing order volumes.

- Consistent product quality: Automated portioning ensures uniform filling for every cake, improving texture, taste, and appearance.

- Cost-effective: Higher efficiency and reduced labor requirements lower operational costs and increase profitability.

Conclusion

This case demonstrates the successful application of the Commercial Cake Filling Machine in the UK market, highlighting its advantages in efficiency, product consistency, and cost reduction for modern bakeries.