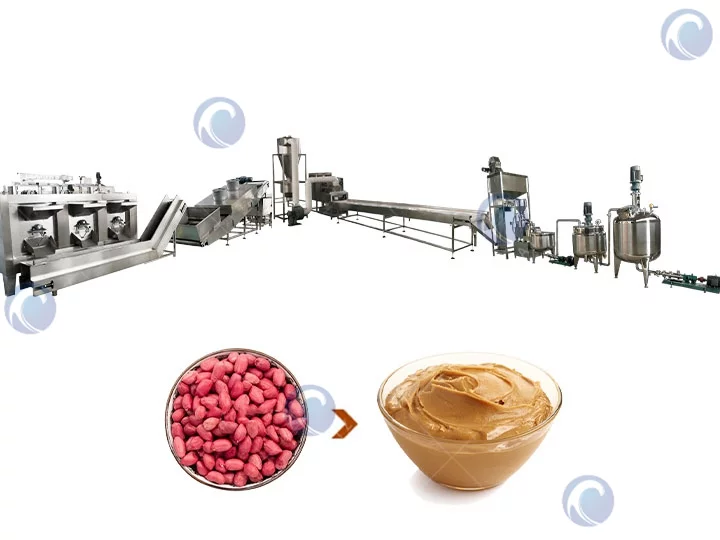

Automatic peanut butter making machine

| نام | Chain Plate Roasting Machine |

| Power (kW) | 130 |

| Dimensions (mm) | 8500 × 1800 × 2600 (effective chain width: 1450) |

| وزن (کلوگرام) | 3000 |

آپ اب ہمارے پروجیکٹ مینیجرز سے تکنیکی تفصیلات پوچھ سکتے ہیں

The automatic peanut butter making machine is a fully integrated and highly automated processing system for the continuous production of high-quality peanut butter, with a flexible capacity ranging from 200 to 2,000 kg/h. It performs a complete series of operations—including roasting, cooling, peeling, grinding, mixing, and filling—to convert raw peanuts into smooth or chunky peanut butter with stable texture and consistent quality.

This production line is designed for medium and large-scale peanut butter processing plants, food factories, and nut product manufacturers. It can process shelled peanuts, roasted peanuts, and other similar nut materials to produce both smooth peanut butter and peanut butter with nut particles, meeting diverse production requirements across different capacity levels.

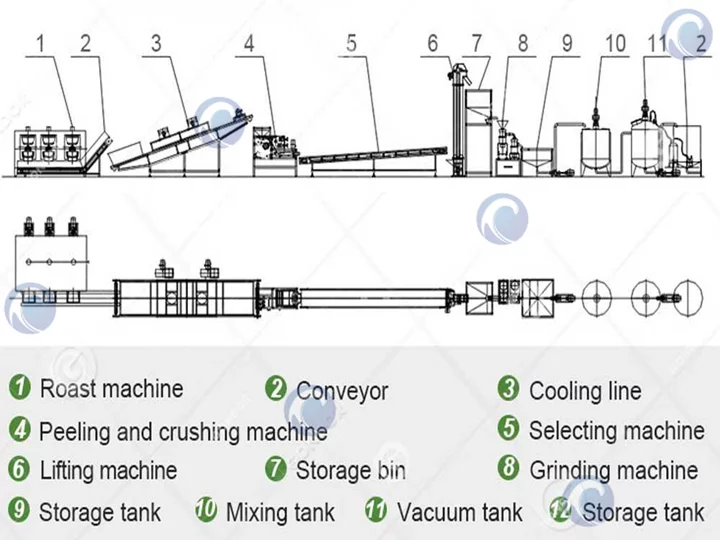

Fully automatic peanut butter making machine working process

The fully automatic peanut butter making machine is a high-efficiency, integrated production line designed to transform raw peanuts into high-quality peanut butter.

With a fully mechanized and enclosed system, the line ensures stable operation, consistent product quality, and minimal manual intervention. Suitable for both medium and large-scale processing, it can produce smooth or chunky peanut butter while maintaining flavor, texture, and hygiene standards.

The production process involves a series of specialized machines working seamlessly together to handle roasting, peeling, grinding, mixing, and filling.

Peanut Roasting Machine

Carefully heats raw peanuts in a controlled environment, evenly roasting them to bring out natural flavors, reduce moisture content, and loosen peanut skins.

This step ensures the peanuts are ready for peeling and contributes to the rich aroma and smooth texture of the final peanut butter.

مونگ پھلی چھلکا اتارنے والی مشین

Removes the red skin from roasted peanuts efficiently while minimizing breakage.

This process not only improves the appearance and taste of the peanut butter but also ensures a smoother texture and consistent quality in the later grinding stage.

Peanut Butter Mill

Grinds peeled peanuts into fine peanut butter. The machine allows adjustment of grinding fineness to produce either smooth or chunky peanut butter.

High-speed milling ensures uniform particle size, consistent texture, and enhanced flavor retention.

Storage and Vacuum Tanks

Stores and mixes the freshly ground peanut butter under vacuum conditions. This removes air bubbles, improves product uniformity, prevents oxidation, and extends shelf life.

The tanks also allow continuous blending of nut pieces for chunky peanut butter.

Filling Machine

Automatically fills the finished peanut butter into jars, bottles, or other containers with precise volume control.

The process is fully enclosed to maintain hygiene, reduce contamination, and increase packaging efficiency, readying the product for sale or distribution.

Peanut butter processing machine benefits

- High Automation: Automatic control with touchscreen interface, easy operation, and minimal manual intervention.

- High Capacity & Efficiency: Continuous production with output from 200–2,000 kg/h, suitable for small to large-scale factories.

- Ultra-Fine & Natural Flavor: Produces smooth peanut butter up to 125–150 mesh, preserving natural taste.

- Versatile Applications: Can process peanuts, sesame, almonds, cocoa, chili, and other nut or seed pastes.

- Customizable Configuration: Adjustable production capacity, processing precision, and equipment setup to meet specific requirements.

- Hygienic & Safe: Made of food-grade stainless steel, fully enclosed design, easy to clean, CE certified.

- Labor-Saving: Reduces labor requirements and ensures stable, continuous production.

- Flexible Product Options: Supports smooth, chunky, sweet, or salty peanut butter, and other specialty pastes.

Peanut butter making machine parameters

| Equipment Name | Power (kW) | Dimensions (mm) | وزن (کلوگرام) |

| Bucket Elevator | 0.75 | 1600 × 750 × 3000 | 260 |

| Chain Plate Roasting Machine | 130 | 8500 × 1800 × 2600 (effective chain width: 1450) | 3000 |

| Bucket Elevator | 0.75 | 900 × 750 × 3000 | 260 |

| Half Kernel Peeling Machine | 3 | 1900 × 800 × 1350 | 500 |

| Sorting Conveyor Belt | 0.75 | 6000 × 800 × 1000 | 400 |

| Bucket Elevator | 0.75 | 900 × 750 × 3800 | 260 |

| Storage Hopper | 0.04 | 1200 × 1100 × 3300 | 200 |

| Colloid Mill (Grinding Machine) | 30 × 2 | 1400 × 1250 × 2000 | 1300 |

| Sauce Storage Tank | — | 1300 × 1300 × 900 (500 L) | 50 |

| Mixing Tank | 3 | 1000 × 1000 × 1900 (500 L) | 200 |

| Vacuum Tank | 3 + 1.5 | 900 × 900 × 2500 (500 L) | 300 |

| Pump | 1.5 × 3 | 1200 × 300 × 350 | 60 × 3 |

| Sauce Storage Tank | — | 900 × 900 × 1200 (500 L) | 150 |

| Control Cabinet | — | — | 50 × 2 |

| Conveying Pipelines | — | — | 100 |

Automatic peanut butter making machine faqs

What information is needed before selecting a suitable model?

Customers usually need to confirm expected daily output, available factory space, power supply conditions, target markets, and packaging requirements so we can recommend the most suitable configuration.

Can the machine be integrated into an existing production line?

Yes, the equipment can be connected with existing upstream or downstream machines, and layout adjustments can be made according to the customer’s workshop conditions.

How long is the delivery time after placing an order?

Delivery time depends on the selected capacity and customization level, typically ranging from several weeks to a few months after order confirmation.

Is installation and commissioning support provided?

Yes, we provide installation guidance, commissioning support, and operator training to ensure smooth startup and stable operation.

What kind of after-sales service is available?

Technical support, spare parts supply, and long-term maintenance guidance are provided to ensure reliable operation throughout the machine’s service life.

Is this machine suitable for first-time peanut butter manufacturers?

Yes, with standardized operation and technical support, the line is suitable for both new investors and experienced processors.

نتیجہ

The automatic peanut butter making machine offers a reliable and scalable solution for manufacturers seeking to upgrade their nut paste production. Designed to support long-term, stable operation and consistent product output, it helps processors improve overall efficiency while maintaining product competitiveness in the market.

Whether you are expanding an existing facility or setting up a new production line, this system provides the flexibility and performance needed for sustainable growth. Contact us today to receive detailed specifications, layout suggestions, and a tailored quotation for your project.