Máquina de descascar amendoim

| Modelo | TZ-GT-4 |

| Poder | 0,75 kW |

| Tamanho | 1100x400x1100mm |

| Taxa de descascamento | 98% |

| Capacidade | 200kg/h |

Agora você pode pedir detalhes técnicos aos nossos gerentes de projeto

A máquina descascadora de amendoim da Taizy está disponível em dois tipos: descascamento a seco e descascamento a úmido, projetada para atender a várias necessidades de processamento. A máquina de descascamento a úmido utiliza um rolo macio de borracha pura de alta qualidade, removendo efetivamente a pele vermelha dos amendoins e adequada para vários materiais, como amendoins e favas.

A máquina de descascamento a seco é ideal para remover a casca vermelha dos amendoins, alcançando uma taxa de descascamento superior a 97%. Oferece tempos de processamento curtos e alta eficiência de trabalho, tornando-se uma máquina indispensável no processamento profundo de amendoim.

Máquina descascadora de amendoim a seco

A máquina descascadora de amendoim a seco é um dispositivo altamente eficiente projetado para remover a pele vermelha dos amendoins. Sua construção inclui vários componentes-chave, como um dispositivo de potência (motor, polia, correia e rolamento), uma estrutura robusta, um funil de alimentação, um rolo descascador (de aço ou diamante) e um sistema de ventilador.

Princípio de funcionamento

A máquina opera com base no princípio de transmissão por atrito de rolagem diferencial. É otimizada para uso com amendoins que têm um teor de umidade inferior a 5%, garantindo que as nozes não se tornem pastosas durante o processamento.

Passos de operação

- Alimentação. Os amendoins são carregados na máquina através do funil de alimentação.

- Descamação. À medida que os amendoins se movem, eles são esfregados contra o rolo de descascamento, separando efetivamente a pele dos grãos.

- Separação. Um sistema de ventilação remove as peles de amendoim soltas, enquanto uma tela vibratória classifica a saída em grãos inteiros de amendoim, metades de grãos e pedaços quebrados.

Seco amendoim parâmetros da máquina de remoção de pele

| Modelo | Poder | Tamanho | Capacidade | Taxa de descascamento |

| TZ-GT-4 | 0,75 kW | 1100x400x1100mm | 200kg/h | 98% |

| TZ-GT-8 | 1,5 kW | 1100x600x1100mm | 400kg/hora | 96% |

| TZ-GT-12 | 2,61 kW | 1180x900x1100mm | 600kg/hora | 96% |

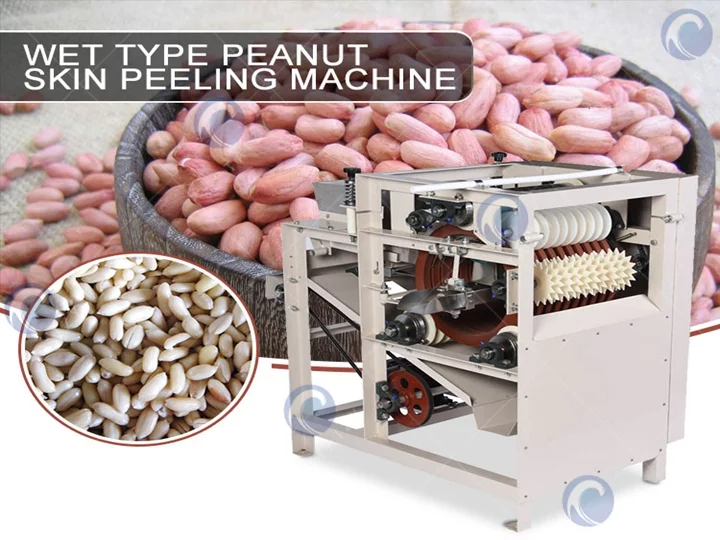

Máquina descascadora de amendoim molhado

A máquina descascadora de amendoim a úmido é especificamente projetada para a remoção eficiente das peles de amendoim e amêndoa, utilizando um processo de descascamento especializado que garante alta qualidade e mínima quebra.

Este equipamento opera com base no princípio de transmissão por atrito de rolagem diferencial, proporcionando uma solução confiável para o processamento de nozes.

Princípio de funcionamento

- Imersão. Antes de descascar, as matérias-primas devem ser imersas em água quente. O tempo e a temperatura de imersão necessários variam com base no tipo de noz.

- Alimentação. Após a imersão, as amêndoas ou amendoins são despejados no funil, onde são vibrados em uma roda de borracha rotativa, que é fixada com três rolos robustos.

- Processo de descascamento. A ação de descascamento é realizada através de uma tira indutora, uma roda de alimentação e um mecanismo de imitação de manivela, garantindo a remoção eficaz da pele.

- Descarte. A roda de descarga empurra as amêndoas descascadas para o funil de descarga, enquanto as peles de amêndoa são expelidas através da roda de camurça.

Parâmetros da máquina de descascar amendoim a úmido

| Modelo | Poder | Tamanho | Capacidade | Taxa de descascamento |

| TZ-100 | 0,55 kW | 1180*720*1100mm | 120-150 kg/hora | 98% |

| TZ-180 | 0,75 kW | 1180*850*1100mm | 200-250 kg/hora | 96% |

Características da máquina descascadora de amendoim

Baixa taxa de quebra. O processo de descascamento a úmido minimiza danos, resultando em nozes de qualidade superior.

Integridade de cor e nutricional. A cor da superfície das nozes descascadas permanece inalterada, e as proteínas essenciais são preservadas.

Separação automática. A máquina separa e descarrega eficientemente as peles e nozes automaticamente durante o processo de descascamento.

Compacta e eficiente. Seu tamanho pequeno, baixo consumo de energia e alta eficiência tornam fácil a operação.

Desempenho confiável. A máquina possui operação estável, segurança, alta produtividade, excelentes efeitos de descascamento e uma baixa taxa de metades.

Aplicações da máquina descascadora de amendoim

A máquina descascadora de amendoim é altamente versátil e encontra aplicações em várias indústrias que exigem o descascamento eficiente de nozes e leguminosas.

- Produção de alimentos para petiscos. Ideal para preparar amendoins e amêndoas descascados usados em vários petiscos e alimentos embalados.

- Fabricação de manteiga de amendoim. Garante amendoins lisos e sem pele para a produção de manteiga de amendoim de alta qualidade.

- Panificação e confeitaria. Fornece nozes perfeitamente descascadas para uso como ingredientes em produtos assados e confeitos.

- Fábricas de processamento de nozes. Usadas em instalações de grande escala para manusear a descascagem de nozes a granel com alta eficiência.

Invista em nossa máquina descascadora de amendoim

Em conclusão, a máquina de descascar amendoim oferece uma solução versátil e eficiente para o processamento de nozes, com sua alta taxa de descascagem, baixa quebra e capacidade de lidar com vários materiais como amendoins, amêndoas e feijões largos.

Além da máquina descascadora de amendoim, também fornecemos uma gama de outras máquinas de processamento de nozes, como máquinas de torrefação, oferecendo soluções completas para otimizar sua linha de produção enquanto mantém alta qualidade do produto.