Sausage Production Line

| Brand | Taizy |

| Machines | Meat cutter, meat grinder, sausage mixer, sausage stuffer, smoked sausage oven, vacuum sealer |

| Warranty | 12 months |

| Note | Support OEM service |

You can now ask our project managers for technical details

A sausage production line means a series of interconnected machines and equipment used to manufacture sausages efficiently and automatically. It involves various steps from material preparation to packing the final product.

We are a professional sausage making machine line manufacturer and exporter. All our machines use durable materials and advanced technology. Besides, all equipment from us enjoys 12 month’s warranty and excellent after-sales service. If you looking for a reliable sausage production line, welcome to contact us for more useful machine details and a free price list.

Brief introduction of sausages and their popularity

Sausages are a globally popular food, loved for their delicious taste and versatility. They have a rich history and have evolved into a wide variety of flavors, shapes, and sizes across different cultures. From breakfast to dinner, sausages offer convenience as they can be quickly cooked in various ways like grilling, frying, baking, or boiling. Their rich and savory flavors, often enhanced with spices and seasonings, make them a favorite choice for meat lovers.

Sausages are a common feature in many cuisines worldwide, appearing in dishes like hot dogs, sausage rolls, and kebabs. Their global appeal and ability to adapt to different culinary traditions have contributed to their enduring popularity.

Types of sausage

Bratwurst, originating from Germany, is a seasoned pork, beef, or veal sausage, while chorizo, popular in Spain and Latin America, offers a spicy and smoky profile. Italian sausages, with sweet and hot variations, are seasoned pork sausages commonly used in Italian cuisine. Andouille, a smoked sausage from Louisiana, adds a robust flavor to Creole and Cajun dishes. Polish kielbasa is a versatile sausage with variations like fresh and smoked, while breakfast sausages are small, seasoned pork sausages enjoyed as part of a morning meal. These are just a few examples of the diverse and delicious types of sausages found worldwide.

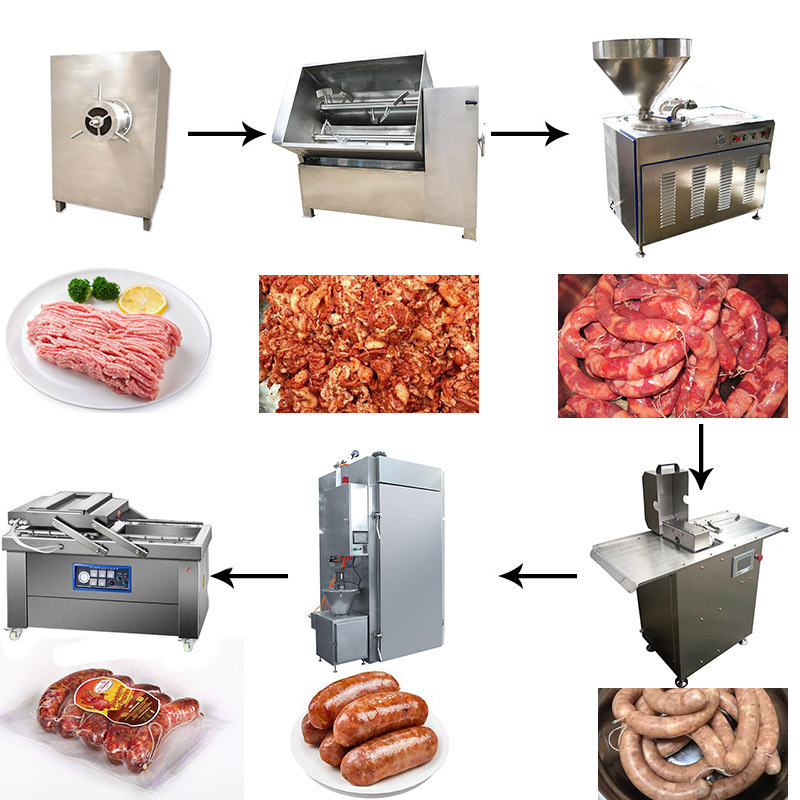

Sausage production processing steps

In this part, you will understand the standard sausage production processing steps, and main steps used to produce sausages are as follow:

1. Raw material preparation: Selection and preparation of high-quality raw materials, such as meat and fat, for sausage production.

2. Grinding the meat: The next step is to grind the meat to achieve the desired consistency and texture for the sausages.

3. Mixing the ingredients: After grinding, the meat is mixed with spices, seasonings, and other ingredients to create a well-blended sausage mixture.

4. Stuffing and filling the sausages: The sausage mixture is then stuffed into casings or tubes, ensuring that the mixture is evenly distributed to form sausages of the desired shape and size.

5. Smoking: Once the sausages are filled, they may undergo the smoking process to enhance flavor and provide a distinct smoky taste. This step is particularly common for certain types of sausages.

6. Packaging and storage: The final step involves packaging the sausages for distribution and storage. This typically includes sealing the sausages in appropriate packaging materials to maintain freshness and extend shelf life.

Main machines of the sausage production line

A sausage production line is a series of single machines, including a meat cutting machine, meat grinding machine, sausage mixing machine, sausage stuffing machine, smoked sausage oven, and vacuum sealer.

Meat cutting machine

This machine is used to cut and prepare the meat into smaller pieces suitable for grinding and mixing.

Meat grinder

It is a machine equipped with rotating blades that grind the meat into the desired consistency. It ensures uniformity and texture in the sausage mixture.

Sausage mixing machine

This machine is designed to blend ground meat with spices, seasonings, and other ingredients thoroughly. It ensures a homogenous distribution of flavors and ingredients.

Sausage stuffing machine

It is a specialized machine used to fill the sausage mixture into casings or tubes. It provides controlled pressure to evenly fill the casings with the desired amount of sausage mixture.

Smoked sausage oven

This machine is used for the smoking process. It generates smoke and provides controlled temperature and airflow to impart a smoky flavor to the sausages. It can be equipped with various smoking methods, such as hot smoking or cold smoking.

Vacuum sealer

It is used to package the sausages by removing air from the packaging to create a vacuum seal. This helps to preserve the freshness and extend the shelf life of the sausages.

Sausage making machine parameters

| Number | Name | Picture | Parameter |

| 1 | Meat grinder machine |  | Capacity:500kg/h Power:3.0kw Voltage:380V/50hz Size:980*580*940mm Weight:180kg |

| 2 | Meat cutting machine |  | Capacity:40kg/time Power:13.17kw Voltage:380V/50H Size:1250*1415*1610mm Weight:480kg |

| 3 | Meat mixer machine |  | Kink speed:100 times/min Production:200-300kg/h Quantitative range: 20-500g Voltage:220V / 50HZ Work center height: 850mm Overall size650*640*1430(mm) Weight:145kg |

| 4 | Sausage filling machine |  | Kink speed:100 times/min Production :200-300kg/h Quantitative range: 20-500g Voltage:220V / 50HZ Work center height: 850mm Overall size650*640*1430(mm) Weight:145kg |

| 5 | Sausage smoked machine |  | Capacity:300-400kg/h Volume:200L Drive power:2.75kw Voltage:380v 50HZ Overall Size:1400*670*1150mm |

| 6 | Vacuum packaging machine |  | Power of pump:2.25KW Heat-sealing power:1.5KW Size:1460*750*960mm Weight:185kg |

Features of sausage making machine line

Sausage making machine line comes with various features that enhance the sausage production process. Here are some common features:

- Automated Operation: Sausage making machine lines are designed for automated operation, reducing the need for manual labor. They can perform tasks such as grinding, mixing, stuffing, linking, and portioning, streamlining the production process and increasing efficiency.

- Precise Mixing and Blending: Sausage making machines have precise mixing and blending capabilities. They ensure consistent distribution of spices, seasonings, and other ingredients throughout the sausage mixture, resulting in uniform flavor and texture.

- Controlled Stuffing Pressure: These machines apply controlled pressure during the stuffing process, ensuring even filling of casings without damaging them. This helps maintain the integrity and appearance of the sausages.

- Temperature and Time Control: Sausage making machine lines often have temperature and time control features. They allow precise control over cooking, smoking, and cooling processes, ensuring optimal results and food safety.

- Easy Cleaning and Maintenance: Machine lines are designed for easy cleaning and maintenance. They have removable parts and smooth surfaces that can be easily accessed and cleaned, reducing downtime between production runs.

- Integration with Packaging Systems: Some sausage making machine lines can be integrated with packaging systems, allowing for seamless transfer of sausages for packaging, labeling, and final storage.

These features collectively contribute to efficient and hygienic sausage production, ensuring consistent quality, customization options, and ease of operation and maintenance.