সসেজ উৎপাদন লাইন

| ব্র্যান্ড | তাইজী |

| যন্ত্রপাতি | মাংস কাটার যন্ত্র, মাংস গ্রাইন্ডার, সসেজ মিক্সার, সসেজ স্টাফার, স্মোকড সসেজ ওভেন, ভ্যাকুয়াম সিলার |

| গ্যারান্টি | ১২ মাস |

| নোট | OEM পরিষেবা সমর্থন |

আপনি এখন আমাদের প্রকল্প ব্যবস্থাপকদের কাছ থেকে প্রযুক্তিগত বিস্তারিত জানতে পারেন

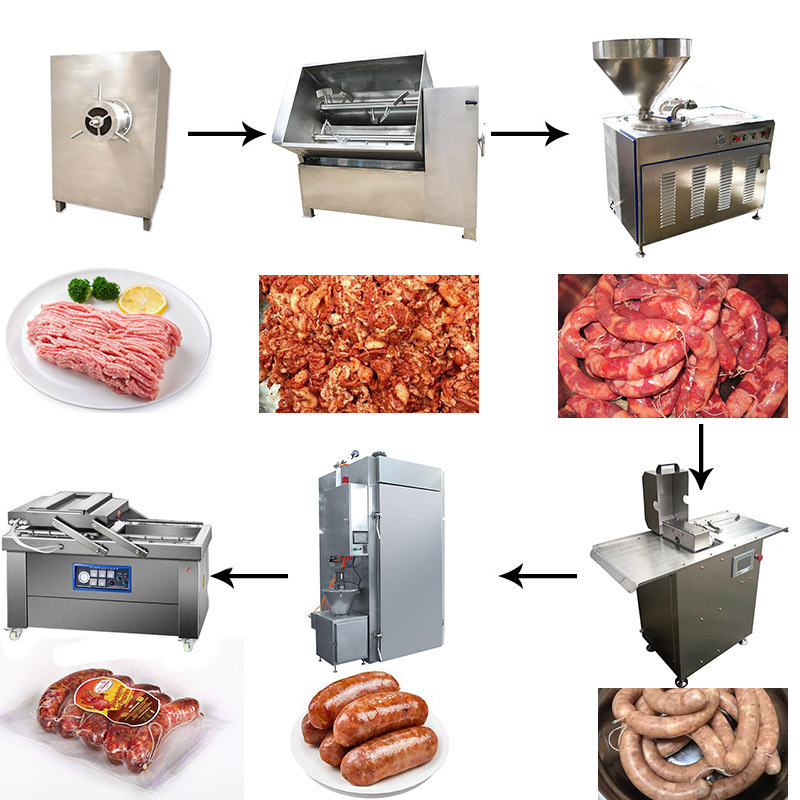

একটি সসেজ উৎপাদন লাইন মানে একটি সিরিজ আন্তঃসংযুক্ত যন্ত্রপাতি এবং সরঞ্জাম যা সসেজগুলি দক্ষ এবং স্বয়ংক্রিয়ভাবে উৎপাদন করতে ব্যবহৃত হয়। এটি উপাদান প্রস্তুতি থেকে চূড়ান্ত পণ্য প্যাকিং পর্যন্ত বিভিন্ন পদক্ষেপ জড়িত।

আমরা একটি পেশাদার সসেজ তৈরির যন্ত্রপাতি লাইন প্রস্তুতকারক এবং রপ্তানিকারক। আমাদের সমস্ত যন্ত্রপাতি টেকসই উপকরণ এবং উন্নত প্রযুক্তি ব্যবহার করে। এছাড়াও, আমাদের থেকে সমস্ত সরঞ্জাম ১২ মাসের গ্যারান্টি এবং চমৎকার বিক্রয়োত্তর পরিষেবা উপভোগ করে। আপনি যদি একটি নির্ভরযোগ্য সসেজ উৎপাদন লাইন খুঁজছেন, তাহলে আমাদের সাথে যোগাযোগ করতে স্বাগতম আরও উপকারী যন্ত্রপাতির বিস্তারিত এবং একটি বিনামূল্যে মূল্য তালিকার জন্য।

সসেজের সংক্ষিপ্ত পরিচিতি এবং তাদের জনপ্রিয়তা

সসেজগুলি একটি বৈশ্বিকভাবে জনপ্রিয় খাবার, তাদের সুস্বাদু স্বাদ এবং বহুমুখীতার জন্য প্রিয়। তাদের একটি সমৃদ্ধ ইতিহাস রয়েছে এবং বিভিন্ন সংস্কৃতিতে বিভিন্ন স্বাদ, আকার এবং আকারে বিবর্তিত হয়েছে। প্রাতঃরাশ থেকে রাতের খাবার পর্যন্ত, সসেজগুলি সুবিধা প্রদান করে কারণ এগুলি দ্রুত বিভিন্ন উপায়ে রান্না করা যায় যেমন গ্রিলিং, ভাজা, বেকিং, বা সেদ্ধ করা। তাদের সমৃদ্ধ এবং স্বাদযুক্ত স্বাদ, যা প্রায়ই মশলা এবং মশলাদার উপকরণ দ্বারা বাড়ানো হয়, মাংস প্রেমীদের জন্য একটি প্রিয় পছন্দ করে তোলে।

সসেজগুলি বিশ্বজুড়ে অনেক রান্নায় একটি সাধারণ বৈশিষ্ট্য, যেমন হট ডগ, সসেজ রোল এবং কাবাব। তাদের বৈশ্বিক আবেদন এবং বিভিন্ন রান্নার ঐতিহ্যের সাথে খাপ খাইয়ে নেওয়ার ক্ষমতা তাদের স্থায়ী জনপ্রিয়তার জন্য অবদান রেখেছে।

সসেজের প্রকারভেদ

ব্রাটওরস্ট, যা জার্মানি থেকে উদ্ভূত, একটি মশলাদার শূকরের, গরুর, বা বীফ সসেজ, যখন চোরিজো, যা স্পেন এবং লাতিন আমেরিকায় জনপ্রিয়, একটি মশলাদার এবং স্মোকি প্রোফাইল প্রদান করে। ইতালীয় সসেজ, মিষ্টি এবং গরম ভেরিয়েশন সহ, সাধারণত ইতালীয় রান্নায় ব্যবহৃত মশলাদার শূকরের সসেজ। অ্যান্ডুইল, লুইজিয়ানার একটি স্মোকড সসেজ, ক্রিওল এবং কেজুন খাবারে একটি শক্তিশালী স্বাদ যোগ করে। পোলিশ কিলবাসা একটি বহুমুখী সসেজ যা তাজা এবং স্মোকডের মতো ভেরিয়েশন রয়েছে, যখন প্রাতঃরাশের সসেজগুলি ছোট, মশলাদার শূকরের সসেজ যা একটি সকালে খাবারের অংশ হিসেবে উপভোগ করা হয়। এগুলি হল বিশ্বজুড়ে পাওয়া বিভিন্ন এবং সুস্বাদু সসেজের কয়েকটি উদাহরণ।

সসেজ উৎপাদন প্রক্রিয়াকরণ পদক্ষেপ

এই অংশে, আপনি সসেজ উৎপাদনের প্রক্রিয়াকরণ পদক্ষেপগুলি এবং সসেজ উৎপাদনের জন্য ব্যবহৃত প্রধান পদক্ষেপগুলি বুঝতে পারবেন:

১. কাঁচামাল প্রস্তুতি: সসেজ উৎপাদনের জন্য উচ্চমানের কাঁচামাল, যেমন মাংস এবং চর্বি নির্বাচন এবং প্রস্তুতি।

২. মাংস গ্রাইন্ডিং: পরবর্তী পদক্ষেপ হল মাংসকে গ্রাইন্ড করা যাতে সসেজগুলির জন্য প্রয়োজনীয় সামঞ্জস্য এবং টেক্সচার অর্জন করা যায়।

৩. উপকরণ মিশানো: গ্রাইন্ড করার পরে, মাংসকে মশলা, সিজনিং এবং অন্যান্য উপকরণের সাথে মিশিয়ে একটি ভাল-মিশ্রিত সসেজ মিশ্রণ তৈরি করা হয়।

৪. সসেজগুলি স্টাফিং এবং ভর্তি করা: সসেজ মিশ্রণটি তারপর কেসিং বা টিউবে স্টাফ করা হয়, নিশ্চিত করে যে মিশ্রণটি সসেজের প্রয়োজনীয় আকার এবং আকার তৈরি করতে সমানভাবে বিতরণ করা হয়েছে।

৫. স্মোকিং: একবার সসেজগুলি ভর্তি হলে, সেগুলি স্বাদ বাড়ানোর জন্য স্মোকিং প্রক্রিয়ার মধ্যে যেতে পারে এবং একটি স্বতন্ত্র স্মোকি স্বাদ প্রদান করতে পারে। এই পদক্ষেপটি বিশেষ করে কিছু ধরনের সসেজের জন্য সাধারণ।

৬. প্যাকেজিং এবং সংরক্ষণ: চূড়ান্ত পদক্ষেপ হল সসেজগুলি বিতরণ এবং সংরক্ষণের জন্য প্যাকেজিং করা। এটি সাধারণত সসেজগুলিকে উপযুক্ত প্যাকেজিং উপকরণে সিল করার অন্তর্ভুক্ত যাতে তাজা রাখা যায় এবং শেলফ লাইফ বাড়ানো যায়।

সসেজ উৎপাদন লাইনের প্রধান যন্ত্রপাতি

একটি সসেজ উৎপাদন লাইন হল একক যন্ত্রপাতির একটি সিরিজ, যার মধ্যে একটি মাংস কাটার যন্ত্র, মাংস গ্রাইন্ডিং মেশিন, সসেজ মিক্সিং মেশিন, সসেজ স্টাফিং মেশিন, স্মোকড সসেজ ওভেন এবং ভ্যাকুয়াম সিলার অন্তর্ভুক্ত।

মাংস কাটার যন্ত্র

এই যন্ত্রটি মাংসকে ছোট টুকরোতে কাটতে এবং প্রস্তুত করতে ব্যবহৃত হয় যা গ্রাইন্ডিং এবং মিশ্রণের জন্য উপযুক্ত।

মাংস গ্রাইন্ডার

এটি একটি যন্ত্র যা ঘূর্ণমান ব্লেড দ্বারা মাংসকে প্রয়োজনীয় সামঞ্জস্যে গ্রাইন্ড করে। এটি সসেজ মিশ্রণে একরূপতা এবং টেক্সচার নিশ্চিত করে।

সসেজ মিক্সিং মেশিন

এই যন্ত্রটি মশলা, সিজনিং এবং অন্যান্য উপকরণগুলি সম্পূর্ণরূপে মিশ্রিত করতে ডিজাইন করা হয়েছে। এটি স্বাদের এবং উপকরণের সমজাতীয় বিতরণ নিশ্চিত করে।

সসেজ স্টাফিং মেশিন

এটি একটি বিশেষায়িত যন্ত্র যা সসেজ মিশ্রণকে কেসিং বা টিউবে ভর্তি করতে ব্যবহৃত হয়। এটি সসেজ মিশ্রণের প্রয়োজনীয় পরিমাণ সমানভাবে কেসিংয়ে ভর্তি করতে নিয়ন্ত্রিত চাপ প্রদান করে।

স্মোকড সসেজ ওভেন

এই যন্ত্রটি স্মোকিং প্রক্রিয়ার জন্য ব্যবহৃত হয়। এটি ধোঁয়া উৎপন্ন করে এবং সসেজগুলিতে স্মোকি স্বাদ দেওয়ার জন্য নিয়ন্ত্রিত তাপমাত্রা এবং বায়ু প্রবাহ প্রদান করে। এটি বিভিন্ন স্মোকিং পদ্ধতির সাথে সজ্জিত হতে পারে, যেমন গরম স্মোকিং বা ঠান্ডা স্মোকিং।

ভ্যাকুয়াম সিলার

এটি প্যাকেজিংয়ের জন্য সসেজগুলি প্যাকেজ করতে ব্যবহৃত হয় যা প্যাকেজিং থেকে বাতাস অপসারণ করে একটি ভ্যাকুয়াম সীল তৈরি করে। এটি সসেজগুলির তাজা রাখা এবং শেলফ লাইফ বাড়াতে সহায়তা করে।

সসেজ তৈরির যন্ত্রপাতির প্যারামিটার

| সংখ্যা | নাম | ছবি | প্যারামিটার |

| 1 | মাংস গ্রাইন্ডার মেশিন |  | ক্ষমতা:500কেজি/ঘণ্টা শক্তি:3.0কিলোওয়াট ভোল্টেজ:380V/50hz আকার:980*580*940মিমি ওজন:180কেজি |

| 2 | মাংস কাটার যন্ত্র |  | ক্ষমতা:40কেজি/বার শক্তি:13.17কিলোওয়াট ভোল্টেজ:380V/50H আকার:1250*1415*1610মিমি ওজন:480কেজি |

| 3 | মাংস মিক্সার মেশিন |  | কিঙ্ক স্পিড:100 বার/মিনিট উৎপাদন:200-300কেজি/ঘণ্টা পরিমাণের পরিসর: 20-500গ্রাম ভোল্টেজ:220V / 50HZ কাজের কেন্দ্রের উচ্চতা: 850মিমি মোট আকার650*640*1430(মিমি) ওজন:145কেজি |

| 4 | সসেজ ফিলিং মেশিন |  | কিঙ্ক স্পিড:100 বার/মিনিট উৎপাদন :200-300কেজি/ঘণ্টা পরিমাণের পরিসর: 20-500গ্রাম ভোল্টেজ:220V / 50HZ কাজের কেন্দ্রের উচ্চতা: 850মিমি মোট আকার650*640*1430(মিমি) ওজন:145কেজি |

| 5 | সসেজ স্মোকড মেশিন |  | ক্ষমতা:300-400কেজি/ঘণ্টা আয়তন:200L ড্রাইভ পাওয়ার:2.75কিলোওয়াট ভোল্টেজ:380v 50HZ মোট আকার:1400*670*1150মিমি |

| 6 | ভ্যাকুয়াম প্যাকেজিং মেশিন |  | পাম্পের শক্তি:2.25KW হিট-সিলিং পাওয়ার:1.5KW আকার:1460*750*960মিমি ওজন:185কেজি |

সসেজ তৈরির যন্ত্রপাতি লাইনের বৈশিষ্ট্য

সসেজ তৈরির মেশিন লাইন বিভিন্ন বৈশিষ্ট্য নিয়ে আসে যা সসেজ উৎপাদন প্রক্রিয়াকে উন্নত করে। এখানে কিছু সাধারণ বৈশিষ্ট্য:

- স্বয়ংক্রিয় অপারেশন: সসেজ তৈরির মেশিন লাইনগুলি স্বয়ংক্রিয় অপারেশনের জন্য ডিজাইন করা হয়েছে, ম্যানুয়াল শ্রমের প্রয়োজনীয়তা কমিয়ে। তারা গ্রাইন্ডিং, মিক্সিং, স্টাফিং, লিঙ্কিং এবং পোর্টিয়নিংয়ের মতো কাজগুলি সম্পাদন করতে পারে, উৎপাদন প্রক্রিয়াকে সহজতর করে এবং দক্ষতা বাড়ায়।

- 正確な混合とブレンド: サ sausage 製造機は正確な混合とブレンド機能を持っています。彼らは、香辛料、調味料、および他の成分の一貫した分配を保証し、サ sausage ミックス全体で均一な風味と食感を実現します。

- নিয়ন্ত্রিত স্টাফিং চাপ: এই মেশিনগুলি স্টাফিং প্রক্রিয়ার সময় নিয়ন্ত্রিত চাপ প্রয়োগ করে, কেসিংগুলির সমানভাবে পূর্ণতা নিশ্চিত করে তাদের ক্ষতি না করে। এটি সসেজের অখণ্ডতা এবং চেহারা বজায় রাখতে সাহায্য করে।

- তাপমাত্রা এবং সময় নিয়ন্ত্রণ: সসেজ তৈরির মেশিন লাইনগুলি প্রায়শই তাপমাত্রা এবং সময় নিয়ন্ত্রণ বৈশিষ্ট্য থাকে। তারা রান্না, স্মোকিং এবং কুলিং প্রক্রিয়ার উপর সঠিক নিয়ন্ত্রণের অনুমতি দেয়, সর্বোত্তম ফলাফল এবং খাদ্য নিরাপত্তা নিশ্চিত করে।

- সহজ পরিষ্কার এবং রক্ষণাবেক্ষণ: মেশিন লাইনগুলি সহজ পরিষ্কার এবং রক্ষণাবেক্ষণের জন্য ডিজাইন করা হয়েছে। তাদের কাছে অপসারণযোগ্য অংশ এবং মসৃণ পৃষ্ঠ রয়েছে যা সহজেই প্রবেশযোগ্য এবং পরিষ্কার করা যায়, উৎপাদন চলাকালীন সময় কমিয়ে।

- প্যাকেজিং সিস্টেমের সাথে একীকরণ: কিছু সসেজ তৈরির মেশিন লাইন প্যাকেজিং সিস্টেমের সাথে একীভূত হতে পারে, প্যাকেজিং, লেবেলিং এবং চূড়ান্ত স্টোরেজের জন্য সসেজগুলির নির্বিঘ্ন স্থানান্তরের অনুমতি দেয়।

এই বৈশিষ্ট্যগুলি সম্মিলিতভাবে কার্যকর এবং স্বাস্থ্যকর সসেজ উৎপাদনে অবদান রাখে, সুনিশ্চিত গুণমান, কাস্টমাইজেশন বিকল্প এবং অপারেশন এবং রক্ষণাবেক্ষণের সহজতা নিশ্চিত করে।