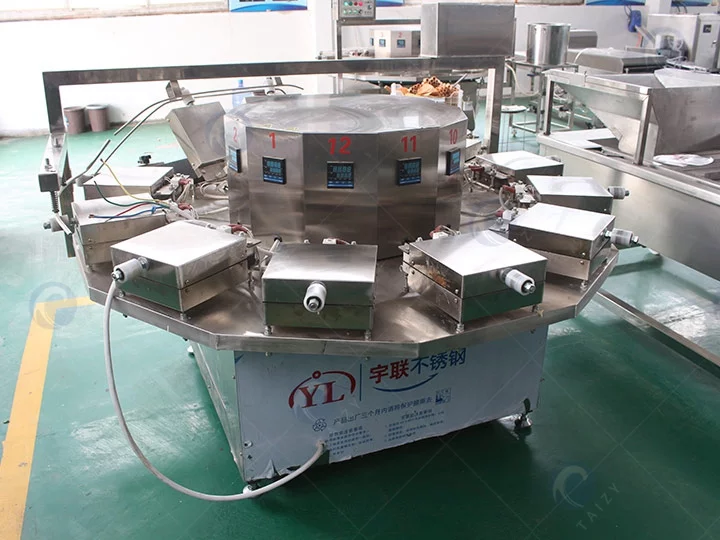

ডিম রোল মেশিন

| মডেল | TZ-9 |

| আকার (মিমি) | 1600*1600*1250 |

| পুরুত্ব (মিমি) | 0.5-4 |

| ভোল্টেজ | 380v/50hz |

| ওজন(কেজি) | 270 |

| ক্ষমতা(পিস/ঘণ্টা) | 400-600 |

আপনি এখন আমাদের প্রকল্প ব্যবস্থাপকদের কাছ থেকে প্রযুক্তিগত বিস্তারিত জানতে পারেন

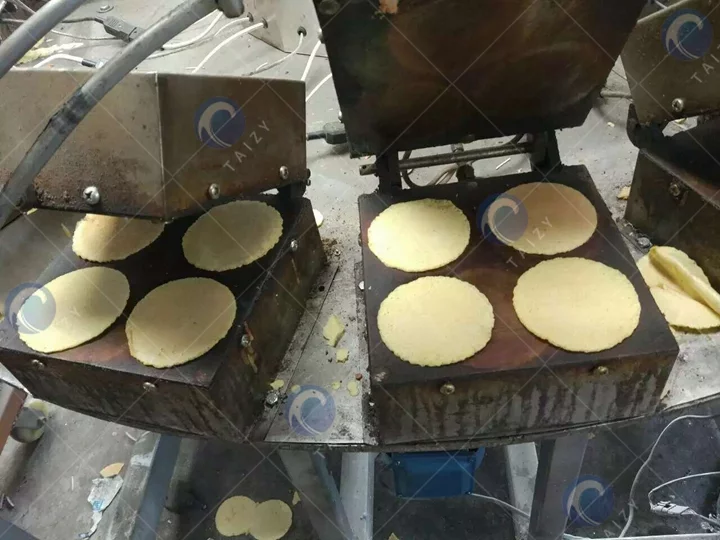

স্বয়ংক্রিয় ডিমের রোল মেশিন অত্যন্ত বহুমুখী, এটি বিভিন্ন ধরনের ক্রিস্পি স্ন্যাক তৈরি করতে সক্ষম। এটি বিভিন্ন ডিমের রোল তৈরি করে, যার মধ্যে পাতলা প্যানকেক, ক্রেপ এবং ক্রিস্পি স্ন্যাক অন্তর্ভুক্ত। তাছাড়া, এটি আইসক্রিমের জন্য নিখুঁত ওয়াফেল কন তৈরি করতে ব্যবহার করা যেতে পারে।

ডিমের রোল তৈরির মেশিনটি ব্যবহারের জন্য ডিজাইন করা হয়েছে, যা শুধুমাত্র একজন অপারেটর প্রয়োজন। উৎপাদন ক্ষমতা 300 থেকে 1200 কেজি/ঘণ্টা এবং কাস্টমাইজযোগ্য ট্রে বিকল্প 6 থেকে 18 পর্যন্ত, এটি উভয়ই নমনীয়তা এবং কার্যকারিতা প্রদান করে। মেশিনটি নিশ্চিত করে যে প্রতিটি পণ্য সমানভাবে ক্রিস্পি, সুস্বাদু এবং দৃষ্টিনন্দন।

ডিমের রোল মেশিন বিক্রয়ের জন্য

আমরা বিভিন্ন উৎপাদন প্রয়োজনীয়তা পূরণের জন্য ডিমের রোল মেশিনের একটি পরিসর অফার করি: 8-হেড, 10-হেড এবং 12-হেড মডেল। প্রতিটি মেশিনে কাস্টমাইজযোগ্য মোল্ড প্যাটার্ন রয়েছে, যার মধ্যে সমতল, বর্গাকার এবং স্ট্রাইপ অন্তর্ভুক্ত, বিশেষ কাস্টমাইজেশন আমাদের 24-ঘণ্টার অনলাইন সমর্থনের মাধ্যমে উপলব্ধ।

আমাদের মেশিনগুলি তাপ প্লেটের আকার কাস্টমাইজ করার অনুমতি দেয় এবং সিলিন্ড্রিকাল রোল, ফিনিক্স রোল এবং আইসক্রিম কন সহ বিভিন্ন আকার তৈরি করতে পারে। এগুলি 380V এবং 220V কনফিগারেশনে উপলব্ধ, বিভিন্ন বৈদ্যুতিক প্রয়োজনীয়তা পূরণ করে।

আমরা একটি বৈশ্বিক বাজারে সেবা দিচ্ছি, যার মধ্যে যুক্তরাষ্ট্র, ভারত, জাপান, দক্ষিণ কোরিয়া, ব্রাজিল, মেক্সিকো, রাশিয়া এবং দক্ষিণ-পূর্ব এশিয়ার দেশগুলি যেমন ইন্দোনেশিয়া, মালয়েশিয়া এবং থাইল্যান্ড অন্তর্ভুক্ত। যদি আপনি আমাদের মেশিনে আগ্রহী হন, তাহলে দয়া করে আমাদের সাথে যোগাযোগ করতে দ্বিধা করবেন না!

আমাদের ডিমের রোল মেশিনের মূল বৈশিষ্ট্যগুলি

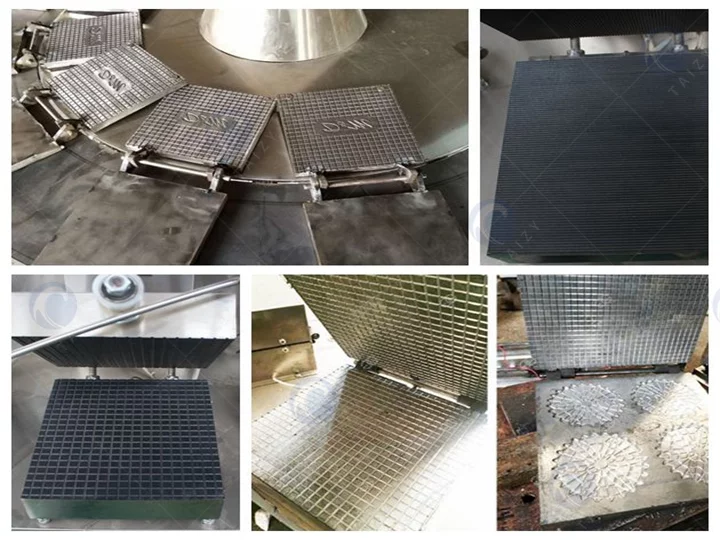

- মজবুত নির্মাণ। একটি পুরু স্টেইনলেস স্টীল ফ্রেম এবং অ্যালুমিনিয়াম মোল্ড দিয়ে তৈরি যা চমৎকার উচ্চ-তাপমাত্রার স্থায়িত্ব প্রদান করে।

- কার্যকরী তাপ। আমদানি করা তাপ-প্রতিরোধী টিউবগুলি বৈশিষ্ট্যযুক্ত যা ধারাবাহিক ফলাফলের জন্য সমান তাপ বিতরণ নিশ্চিত করে।

- সঠিক তাপমাত্রা নিয়ন্ত্রণ। 正確な温度設定は、正確な調理のために160-175°Cの範囲で調整可能です。

- স্বয়ংক্রিয় পেস্টিং। গ্রাউটিং প্রক্রিয়ার সময় পেস্টের ছড়িয়ে পড়া প্রতিরোধ করে।

- নন-স্টিক তাপ প্লেট। তেল ব্রাশিংয়ের প্রয়োজন নেই, যা ডিমের রোলগুলি সহজে সরিয়ে নেওয়ার অনুমতি দেয়।

- সমান রান্না। ল্যাটিস-প্যাটার্নযুক্ত তাপ শীটগুলি সমান তাপ বিতরণ নিশ্চিত করে।

- কাস্টমাইজযোগ্য আকার এবং পুরুত্ব। গ্রাউটিং পরিমাণ পরিবর্তন করে ডিমের রোলের আকার এবং পুরুত্ব সামঞ্জস্য করুন।

- সামঞ্জস্যযোগ্য গতি। অপারেটরের অভিজ্ঞতার ভিত্তিতে গতি সেটিংস পরিবর্তন করা যেতে পারে।

- বৈশিষ্ট্যযুক্ত তাপমাত্রা সেটিংস। প্রতিটি তাপ প্লেট আলাদাভাবে নিয়ন্ত্রণ করা যেতে পারে, 0 থেকে 200°C এর মধ্যে।

- স্বয়ংক্রিয় প্লেট সমন্বয়। উৎপাদন ব্যাহত না করে প্লেট প্রতিস্থাপন সহজ করে।

- নমনীয় সূত্র। সমুদ্রের শৈবাল, ক্রিম, বেগুনি আলু, ওটস, তিল, চকলেট এবং দুধের গুঁড়ো সহ বিভিন্ন উপাদানকে গ্রহণ করে।

ডিমের রোল র্যাপার মেশিনটি কীভাবে কাজ করে?

- সেটআপ

- যে সমস্ত অংশ সঠিকভাবে ইনস্টল করা হয়েছে তা চেক করুন।

- মেইন সুইচটি চালু করুন; পাওয়ার ইন্ডিকেটর জ্বলে উঠবে।

- প্রস্তুতি

- ইনজেকশন ভোল্টেজ প্লাগ এবং ট্রেকিয়া প্রবেশ করান, তারপর এয়ার পাম্পটি সক্রিয় করুন।

- হিটিং বক্স এবং টার্নটেবিল শুরু করতে অপারেশন বোতামটি চাপুন।

- গরম করা

- হিটিং সুইচটি চালু করুন।

- ডিমের রোলের পুরুত্ব অনুযায়ী কন্ট্রোলারে কাঙ্ক্ষিত তাপমাত্রা সেট করুন।

- সমন্বয়

- পেস্ট স্টিকটি ৫ ডিগ্রি উপরে ঝুঁকান এবং এটি হিটিং বক্সে রাখুন।

- যখন সেট করা তাপমাত্রা পৌঁছায়, তখন স্বয়ংক্রিয় পেস্ট প্রয়োগ শুরু করতে পেস্ট সুইচটি চালু করুন।

- উৎপাদন

- যন্ত্রটি ১৫ মিনিটের জন্য গরম করুন।

- উপরের এবং নীচের অংশে হালকা তেল লাগান।

- স্বয়ংক্রিয় পেস্ট ড্রপিংয়ের জন্য কাঁচামাল পাম্পটি সংযুক্ত করুন, তারপর এক চক্র পরে ডিমের রোলের মোড়কটি সরান।

এই সোজা প্রক্রিয়া নিশ্চিত করে ডিমের রোলের মোড়কগুলির কার্যকর এবং ধারাবাহিক উৎপাদন।

ডিমের রোল তৈরির মেশিনের প্রযুক্তিগত প্যারামিটারগুলি

| মডেল | আকার (মিমি) | পুরুত্ব (মিমি) | ডিমের রোলের ব্যাস (সেমি) | ভোল্টেজ | ওজন(কেজি) | ক্ষমতা(পিস/ঘণ্টা) |

| TZ-6 | 1400*1400*1250 | 0.5-4 | 7-20 | 380v/50hz | 250 | 300 |

| TZ-9 | 1600*1600*1250 | 0.5-4 | 7-20 | 380v/50hz | 270 | 400-600 |

| TZ-12 | 1950*1950*1700 | 0.5-4 | 7-20 | 380v/50hz | 300 | 600-800 |

| TZ-15 | 2050*2050*1750 | 0.5-4 | 7-20 | 380v/50hz | 330 | 800-1000 |

ডিমের রোলার মেশিনের চূড়ান্ত পণ্য

স্বয়ংক্রিয় ডিমের রোল মেশিনের সহায়ক যন্ত্রপাতি

মিশ্রণ মেশিন

- গঠন: মিক্সিং মেশিন সাধারণত একটি শরীর, একটি বৈদ্যুতিক মোটর এবং একটি মিক্সিং ডিভাইস নিয়ে গঠিত। শরীরটি সাধারণত স্বাস্থ্য এবং নিরাপত্তা নিশ্চিত করতে স্টেইনলেস স্টিলের তৈরি হয়।

- ফাংশন: মিক্সিং মেশিনটি মূলত ডিমের রোলের জন্য উপাদানগুলি মিশ্রিত করতে ব্যবহৃত হয়। এর মিক্সিং ডিভাইসটি বিভিন্ন উপাদান দ্রুত এবং সমানভাবে মিশ্রিত করতে পারে, যা ভর্তি সামগ্রীর সমান সঙ্গতি নিশ্চিত করে, ফলে ডিমের রোলের গুণমান এবং টেক্সচার উন্নত হয়।

রোলিং মেশিন

- গঠন: রোলিং মেশিন সাধারণত রোলার, একটি ট্রান্সমিশন মেকানিজম এবং অন্যান্য উপাদান নিয়ে গঠিত। রোলারগুলি সাধারণত খাদ্য নিরাপত্তা নিশ্চিত করতে খাদ্য-গ্রেড উপকরণ দিয়ে তৈরি হয়।

- ফাংশন: রোলিং মেশিনটি ডিমের রোলের বেকড বাইরের স্তরকে একটি সমান আকারে রোল করতে ব্যবহৃত হয়। রোলারগুলির গতি এবং চাপ সমন্বয় করে নিশ্চিত করা হয় যে ডিমের রোলটি একটি শক্তভাবে রোল করা অবস্থায় থাকে।

ফর্মিং মেশিন

- গঠন: গঠন মেশিনটি নির্দিষ্ট প্রয়োজনীয়তার অনুযায়ী কাস্টমাইজ করা যায় এমন ছাঁচ নিয়ে ডিজাইন করা হয়েছে।

- ফাংশন: গঠন মেশিনটি রোল করা ডিমকে তার চূড়ান্ত আকার দিতে দায়ী। এটি ডিমের রোলের আকার দিতে পূর্বনির্ধারিত ছাঁচ ব্যবহার করে, নিশ্চিত করে যে এটি কাঙ্ক্ষিত আকার বজায় রাখে।

ডিমের রোল মেশিনের দাম

ডিমের রোল মেশিনের দাম বেকিং প্লেটের সংখ্যা, গরম করার পদ্ধতি এবং অর্ডারের পরিমাণের মতো ফ্যাক্টরের উপর নির্ভর করে। এই কার্যকর যন্ত্রটি টেকসই স্টেইনলেস স্টিল এবং অ্যালুমিনিয়াম থেকে তৈরি, যা সঠিক তাপমাত্রা নিয়ন্ত্রণ এবং সমান রান্নার জন্য উন্নত হিটিং টিউবগুলি বৈশিষ্ট্যযুক্ত।

আকার, পুরুত্ব এবং তাপমাত্রার জন্য কাস্টমাইজযোগ্য সেটিংসের মতো অতিরিক্ত বৈশিষ্ট্যগুলি যন্ত্রটির বহুমুখীতায় অবদান রাখে। প্লেটের সংখ্যা এবং গরম করার পদ্ধতির সাথে দাম পরিবর্তিত হতে পারে, এবং বৃহৎ ক্রয়ে ছাড় পাওয়া যেতে পারে।

আমাদের সাথে যোগাযোগ করুন!

সংক্ষেপে, আমাদের ডিমের রোল মেশিনটি এর টেকসই নির্মাণ, সঠিক তাপমাত্রা নিয়ন্ত্রণ এবং কার্যকর স্বয়ংক্রিয় কার্যাবলী সহ standout করে, যা উচ্চ-মানের ডিমের রোল উৎপাদনের জন্য একটি চমৎকার পছন্দ। কাস্টমাইজযোগ্য সেটিংস এবং বহুমুখী বৈশিষ্ট্যগুলির সাথে, এটি প্রতিটি ব্যাচের সাথে ধারাবাহিক এবং সুস্বাদু ফলাফল নিশ্চিত করে।

অতিরিক্তভাবে, আমরা বিভিন্ন উৎপাদন প্রয়োজনীয়তা পূরণের জন্য অন্যান্য খাদ্য প্রক্রিয়াকরণ মেশিনের একটি পরিসর অফার করি, যার মধ্যে আইসক্রিম কন তৈরির মেশিন, কুকি তৈরির মেশিন, এবং কাপকেক ভর্তি মেশিন। আপনার উৎপাদন প্রয়োজনীয়তার জন্য নিখুঁত সমাধান খুঁজে পেতে আমাদের সম্পূর্ণ পণ্য লাইনআপ অন্বেষণ করুন।