Cocoa Bean Sheller Machine

| Model | Kt-2 Type Peel & Kernel Separator |

| Dimensions (cm) | 120*110*120 |

| Production Capacity | 200KG/H |

| Voltage | 380V |

| Motor Power | 0.75KW |

| Fan Power | 0.55KW |

| Stripping Rate | >98% |

| Weight (kg) | 140 |

You can now ask our project managers for technical details

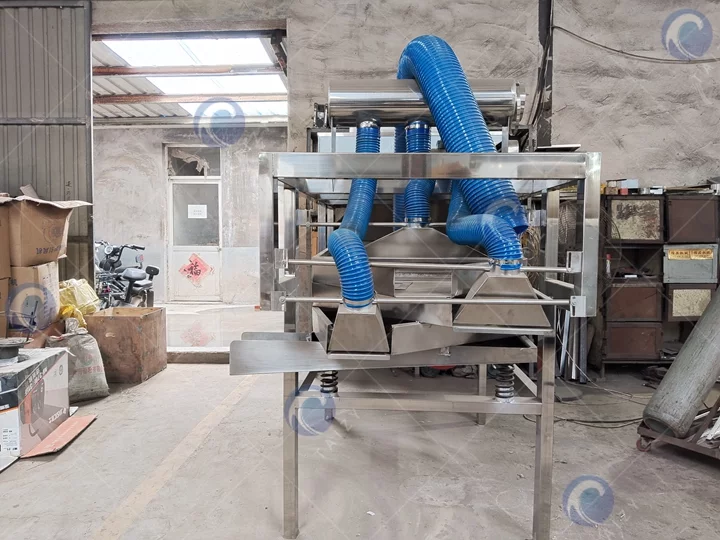

The Cocoa Bean Sheller Machine is mainly used for crushing, shelling, and separating nibs from shells. The machine features a compact structure and combines peeling rollers, a blower, and separation sieves, offering simple operation, stable performance, and a high shelling rate.

It is widely applied in chocolate and cocoa product production lines, effectively improving raw material utilization and product quality.

Depending on the model, the machine’s capacity ranges from 50–1000 kg/h, with a shelling rate of over 98%, and power configurations from 0.4 kW to 4.4 kW, making it suitable for diverse requirements from small processing workshops to large-scale production enterprises.

Cocoa bean peeling machine for sale

Our cocoa bean peeling machine quickly and cleanly separates shells from nibs. The machine is equipped with three powerful fans and three vibrating screens, ensuring precise grading and effective shell removal. It also comes with a conveyor system, which allows continuous feeding and smooth operation.

The airflow intensity is adjustable, giving operators full control over the peeling process. In cases where the shells are not completely removed in the first round, the conveyor automatically returns the beans into the machine for secondary peeling, resulting in a cleaner and higher peeling rate.

Cocoa bean shelling machine structure

The cocoa bean sheller machine is built with a compact yet efficient structure that integrates multiple processing components to ensure smooth operation.

It mainly consists of a feeding hopper, peeling rollers, vibrating screens, fans (blowers), and a cyclone system for shell collection.

How does the cocoa bean sheller machine work?

- Feeding – Cocoa beans are evenly fed into the hopper.

- Shelling – The beans are rolled and shelled by the peeling rollers.

- Screening – The shelled beans fall onto the vibrating screen, where they are separated according to different particle sizes.

- Shell removal – With the help of the blower, the separated shells of different sizes are sucked out and collected in the cyclone storage system.

- Nib discharge – The cleaned cocoa nibs are discharged from the outlet.

- Adjustment – By regulating the airflow intensity and the gap between peeling rollers, complete separation of shells and nibs can be achieved.

Cocoa bean sheller machine advantages

- The machine is made entirely of 304 stainless steel, ensuring durability and hygiene.

- High automation allows fast shelling with low noise and minimal manual labor.

- It can efficiently process both cocoa beans and peanuts for industrial use.

- A built-in vacuum dust collector captures red skins and keeps the environment clean.

- Adjustable fans and vibrating screens ensure thorough shell separation with secondary peeling for incomplete beans.

- Easy operation and maintenance reduce downtime and ensure smooth workflow.

Cocoa bean sheller machine parameters

| Model | Technical Parameters | Dimensions (cm) | Production Capacity | Voltage | Motor Power | Fan Power | Stripping Rate | Weight (kg) |

| Kt-2 Series (Basic) | Basic Model | 70*60*130 | 50-100kg/h | 380V 50HZ | 0.4KW | 0.37KW | – | – |

| Kt-2 Series (with Cyclone) | With Cyclone Separator | 100*100*130 | 50-100kg/h | 380V 50HZ | 0.4KW | 0.37KW | – | – |

| Kt-2 Type Peel & Kernel Separator | Peel & Kernel Separator | 120*110*120 | 200KG/H | 380V | 0.75KW | 0.55KW | >98% | 140 |

| Kt-4 Type | Type Kt-4 | 140*60*130 | 100KG/H | 380V | 0.75KW | 1.1KW | >99% | 150 |

| Kt-3 Type Peel, Screen & Kernel Separator | Type Kt-3 | 160*70*140 | 300KG/H | 380V | 0.75KW | 1.5KW | >99% | 200 |

| Kt-4 Type Advanced Peel, Screen & Kernel Separator | Advanced Type Kt-4 | 160*100*140 | 400-500KG/H | 380V | 1.1KW | 2.2KW | >99% | 280 |

| HB-2 Type Spiral Peeler | Spiral Peeler | 1900*1000*1400 | 1000kg/h | 380V 50HZ | 4.4KW (adjustable speed motor) | 2.2KW | – | 300 |

Using tips of cocoa bean sheller machine

- Place the machine on a level, stable surface.

- Ensure proper ventilation to prevent motor overheating.

- Check all parts, blades, and fasteners before operation.

- Avoid overloading beans to prevent blockages.

- Wear protective gloves and avoid touching moving parts.

- Clean bean shells and dust regularly.

- Perform routine maintenance on wear parts.

- Always power off before cleaning or adjustments.

Conclusion

The Cocoa Bean Sheller Machine is the perfect solution for producing clean, high-quality cocoa nibs with minimal waste, making it an ideal choice for both small-scale and industrial cocoa processing operations.

In addition, our company offers a full range of nut processing machinery, and we welcome you to browse our products and request a quote.