Noodle maker machine

| Name | Noodle making machine |

| Size | 800*720*1650mm |

| Weight | 400kg |

| Power | 11kw |

| Capacity | 30-130kg/h |

| Voltage | 380v |

You can now ask our project managers for technical details

Multifunctional noodle maker machine efficiently processes flour, water, and other raw materials into various types of noodles, including corn noodles, buckwheat noodles, and rice noodles, with different thicknesses.

Utilizing continuous extrusion, this versatile corn noodle maker machine transforms ingredients effortlessly into delicious noodles.

With a capacity of 30 to 130 kg/h, it is well-suited for both catering and food processing applications, offering reliable performance and flexibility for high-demand environments.

Noodle varieties with our multifunctional noodle maker

Our multifunctional noodle maker can produce a variety of noodles, including:

- Classic Italian pasta. Create traditional pasta types such as spaghetti, fettuccine, and tagliatelle.

- Corn noodles. Easily make delicious corn noodles for various dishes.

- Buckwheat noodles. Produce unique and flavorful buckwheat noodles that are both healthy and tasty.

- Rice noodles. Make delicate rice noodles, perfect for Asian-inspired dishes.

- Konjac noodles. Prepare low-calorie, high-fiber konjac noodles, ideal for those seeking a healthy alternative.

Having explored the various types of noodles our multifunctional noodle maker can produce, we will now delve into how the Konjac noodle making machine works, providing a deeper understanding of its functionality and operation.

How does the konjac noodle maker machine work?

- Step 1: Dough Preparation

- Mix flour and water in the proper ratio.

- Ensure the dough has the right stickiness and elasticity for extrusion.

- Step 2: Feeding the Dough

- Place the prepared dough into the machine’s feeding port.

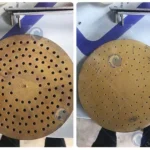

- Step 3: Extrusion Process

- Inside the machine, a screw extrusion system pushes the dough forward.

- The dough is pressed through the die holes, forming noodles of the desired shape and size.

After grasping the working process, we will move on to discuss the specific parameters of the noodle making machine, helping you understand its technical specifications and performance features for informed investment decisions.

Parameters of noodle making machine

- Size: 800*720*1650mm

- Voltage: 380v

- Weight: 400kg

- Power: 11kw

- Capacity: 30-130kg/h

Once you have a detailed understanding of the machine’s parameters, we will explore how supplementary equipment can enhance noodle production efficiency, providing you with a comprehensive solution.

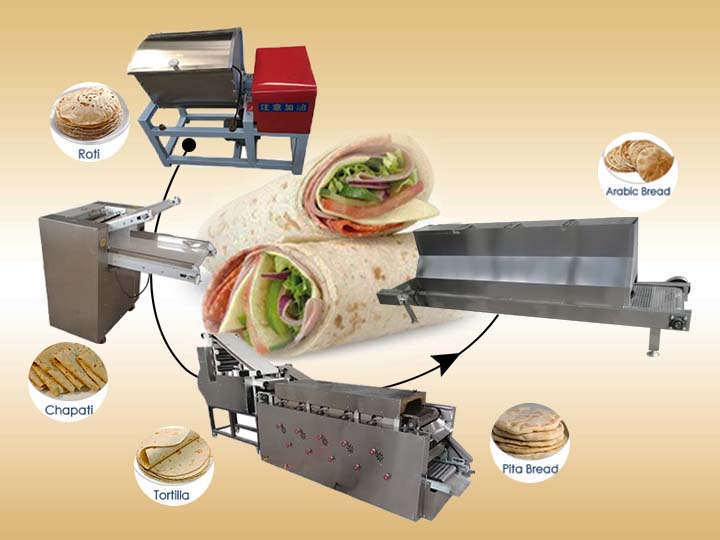

Supplementary equipment of noodle maker machine

In addition to the noodle maker machine itself, we also offer supplementary equipment including the flour mixing machine, cutting machine, and drying machine, to facilitate the noodle making process.

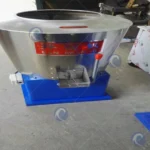

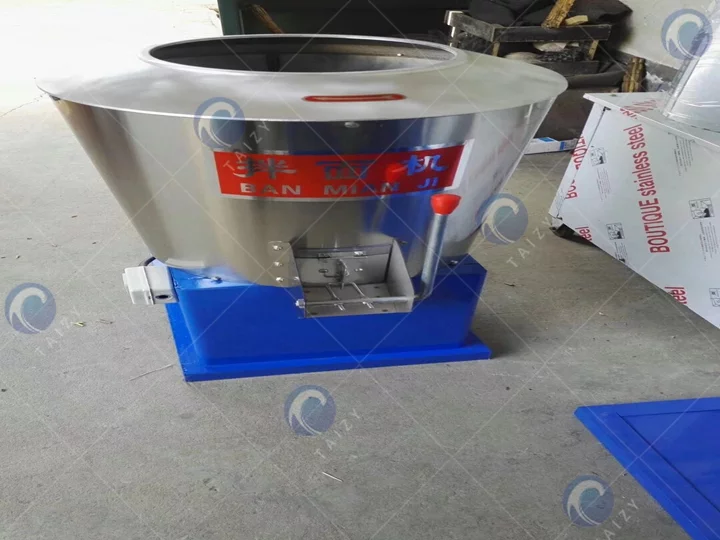

Flour mixing machine

The flour mixing machine helps you thoroughly mix flour and water, ensuring the dough’s even texture and softness. It quickly mixes the flour, eliminating the tedious process of hand mixing and making it easier for you to prepare the dough.

Cutting machine

The cutting machine allows you to cut the extruded dough into the desired length and shape, such as spaghetti or wide noodles. It’s easy to operate and can quickly and accurately cut the noodles, ensuring consistent shape and size.

Drying machine

The drying machine helps you quickly dry the freshly made noodles, extending their shelf life. It utilizes temperature and humidity control technology to quickly and evenly dry the noodles, maintaining their texture and taste.

With an understanding of the supplementary equipment’s functions, we will proceed to discuss the benefits of investing in a noodle maker machine, helping you assess its value and advantages.

Noodle maker machine advantages

- Variety of noodle types: Multiple molds produce thin, wide, pasta, and hollow noodles.

- Durable & safe: Made of stainless steel or food-grade plastic for long-term, food-safe use.

- Instant noodle production: Quickly makes instant noodles for busy lifestyles.

- Efficient design: Stainless steel body and non-stick molds ensure smooth operation.

- Enhanced feature: Double fan system prevents noodles from sticking.

Having discussed the numerous benefits of investing in a noodle maker machine, we will now explore why noodles have become so popular globally, offering additional market context.

Why does eating noodles become so popular?

- Quick energy boost: Rich in carbohydrates for fast energy before or after exercise.

- Nutritional variety: Whole wheat noodles add fiber; bean or protein noodles boost protein intake.

- Diverse choices: Includes Italian pasta, buckwheat noodles, and konjac noodles for different tastes and diets.

- Flexible cooking: Can be boiled, fried, or steamed and paired with various ingredients.

- Convenient preparation: Quick and easy to make, ideal for busy lifestyles.

Conclusion

Noodle Maker Machine supports the production of multiple noodle varieties—from corn and rice noodles to konjac and buckwheat.

Thanks to continuous extrusion design and optional supporting equipment (mixers, cutters, dryers), this machine is well suited for both small-scale shops and food processing plants seeking consistent quality, operational ease, and product diversity.