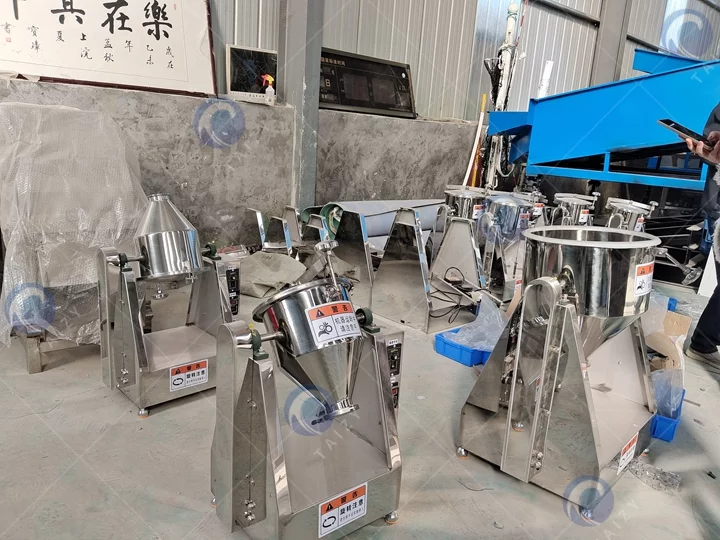

가루 혼합기 기계

| 모델 | GH100-B |

| 크기 | 1200*815*1200mm |

| 용량 | 180L |

| 드럼 속도 | 28rpm |

| 주축 속도 | 40-41rpm |

| 전력 | 380V 4극 3KW |

이제 저희 프로젝트 관리자에게 기술 세부 정보를 요청할 수 있습니다

가루 혼합기 기계는 효율적이고 균일한 혼합을 위해 설계되었으며, U형 및 드럼형 구성으로 제공됩니다. 조미료 가루, 밀크티 가루, 커피 가루 및 기타 미세 재료 혼합에 널리 사용됩니다. 조정 가능한 혼합 속도로 혼합 일관성을 정밀하게 제어할 수 있습니다.

이 기계는 재료 접촉 부품에 304 스테인리스 스틸을 사용하고 프레임에 201 스테인리스 스틸을 사용하여 내구성과 위생을 보장합니다. 60L에서 490L까지의 용량 범위를 제공하며, 우리의 가루 혼합기는 호주, 미국 및 페루에 성공적으로 수출되어 다양한 산업에서 신뢰성을 입증했습니다.

적합한 가루 혼합기 기계를 선택하는 방법은?

가루 혼합기 기계를 선택할 때 U형 믹서와 드럼 믹서 간의 선택은 가루의 고운 정도, 생산 능력 및 운송 포장 요구 사항 등 여러 요인에 따라 달라집니다.

1. 가루 고운 정도

- U형 믹서. Ideal for materials that require a higher degree of fineness. The U-trough design allows for more intensive mixing, making it suitable for fine powders such as spices, tea powder, and coffee powder. The U-trough mixer ensures a homogeneous blend with minimal particle size variation.

- Drum mixer. Suitable for materials that do not require extremely fine mixing. The drum mixer provides a gentle mixing action, making it ideal for powders that are less sensitive to particle size, such as certain types of feed or industrial materials.

2. 생산 능력

- U형 믹서. Available in larger capacities, with the smallest model capable of handling 100kg per batch. U-trough mixers are suitable for medium to large-scale production, with capacities ranging from 100kg to 1000kg.

- Drum mixer. Typically has a smaller capacity range, suitable for small to medium-scale production. Drum mixers can handle batches ranging from 2kg to 300kg, making them ideal for operations that require flexibility in batch sizes.

3. 운송 및 포장

- U형 믹서. The U-trough design allows for easier cleaning and maintenance, which is beneficial for operations that require frequent changes in packaging materials. The mixer’s design also ensures minimal residue, making it easier to package the final product.

- Drum mixer. The drum mixer’s compact design makes it easier to transport and install in various locations. This is particularly useful for operations that require mobile mixing solutions or have space constraints.

특별 고려 사항

- U형 믹서. Recommended for applications where the powder’s fineness and homogeneity are critical, such as in the food and pharmaceutical industries. The U-trough mixer’s ability to handle larger batches also makes it suitable for high-volume production.

- Drum mixer. Ideal for operations that require gentle mixing and have lower capacity needs. The drum mixer’s simplicity and ease of use make it a cost-effective solution for small to medium-scale production.

When choosing between a U-trough and drum mixer for your Powder Blender Machine, consider the specific requirements of your application, including the desired fineness of the powder, production capacity, and transportation needs.

For high-volume production and fine powder requirements, the U-trough mixer is the recommended choice. For smaller batches and gentle mixing needs, the drum mixer is an excellent option.

드럼 가루 혼합 기계 매개변수

| 모델 | External size(mm) | Drum size(mm) | Capacity (L) | Power supply | Discharge port size | Drum speed (rpm) | Main shaft speed (rpm) |

| GH30-B | 940*630*1000 | 390*710 | 60 | 220V 4-pole 2.2KW | 35cm 108 valve | 28 | 82-84 |

| GH50-B | 1000*670*1000 | 450*830 | 90 | 220V 4-pole 3KW | 35cm 108 valve | 28 | 82-84 |

| GH100-B | 1200*815*1200 | 570*1000 | 180 | 380V 4극 3KW | 35cm 108 valve | 28 | 40-41 |

| GH200-B | 1360*1000*1400 | 780*1200 | 400 | 380V 4극 3KW | 35cm 133 valve | 20 | 40-41 |

| GH300-B | 1700*1400*1900 | 900*1400 | 490 | 380V 4극 3KW | 50cm 159 valve | 20 | 40-41 |

U-trough coffee mixer 기계 매개변수

| 모델 | External Dimensions (mm) | Capacity (L) |

| TZ-60 | 570*600*1000 | 100 |

| TZ-100 | 700*830*1100 | 100 |

커피 혼합 기계의 장점

- Dual-mode flexibility. U-Type for coarse/low-fluidity powders (e.g., laundry detergent), Drum-Type for fine powders (e.g., coffee, spices).

- Precision mixing. Adjustable speed (0-1500 rpm) ensures uniform blending across densities.

- Durable & hygienic. 304 stainless steel (contact parts) + 201 steel frame, corrosion-resistant and food-safe.

- Scalable capacity. 60L-490L models (customizable up to 1000kg batches).

- Globally certified. Complies with FDA, TGA, and international standards.

- Stable operation. Low-speed drum rotation (20-28 rpm) minimizes heat; high-torque motors (2.2-4KW) ensure reliability.

- Easy logistics. Modular Drum-Type design for quick assembly/export; standardized discharge ports (35-50cm).

가루 혼합기 기계의 보조 장비

The Powder Blender Machine can be used in conjunction with a coarse crusher to achieve optimal mixing results. Here are some key points to consider:

- Coarse crushing before blending. For materials like chili peppers, it is common to use a coarse crusher to initially break down the material to a size of 10-15 mesh. This coarse crushing step ensures that the material is suitable for further fine grinding.

- Fine grinding with toothed disk mill. After coarse crushing, the material can be further processed using a toothed disk mill to achieve a finer powder. This step is essential for achieving the desired consistency for products such as spices, coffee powder, and other fine powders.

- Capacity of coarse crusher. The coarse crusher can handle up to 60 mesh, with a processing capacity of around 300-400 kg per hour. This makes it an efficient choice for preparing materials for the Powder Blender Machine.

- Limitations with root and tuber crops. It is important to note that root and tuber crops should not be directly processed using a toothed disk mill for fine grinding, as this can lead to clogging of the screen. Instead, these materials should first be processed using a suitable coarse crusher to achieve the appropriate particle size before further grinding.

By integrating a coarse crusher with the Powder Blender Machine, you can ensure efficient and effective processing of a wide range of materials, from coarse crushing to fine grinding, while maintaining optimal performance and avoiding potential issues such as screen clogging.

결론

분말 혼합기는 다양한 분말 재료의 효율적이고 균일한 혼합을 보장하여 식품 가공, 제약 및 화학 산업과 같은 분야에서 필수 도구입니다. 조절 가능한 속도, 다양한 용량 옵션 및 내구성 있는 스테인리스 스틸 구조를 갖춘 이 기계는 고품질 혼합을 달성하기 위한 신뢰할 수 있는 솔루션을 제공합니다.

생산을 더욱 간소화하기 위해, 우리의 파우더 포장 기계는 공정에 통합될 수 있어 최종 제품의 정밀하고 효율적인 포장을 가능하게 합니다. 이 원스톱 솔루션은 혼합에서 포장으로의 원활한 전환을 보장하여 생산성과 편리함을 향상시킵니다. 오늘 저희에게 연락하여 파우더 블렌딩 및 포장 설정을 맞춤화하세요!