सब्जियों और फलों की धोने और छीलने की मशीन के प्रमुख कार्य

सब्जियों और फलों की धोने और छिलने की मशीन की कार्यक्षमता के मूल में एक जटिल कार्य सिद्धांत है जो फल और सब्जी ब्रश सफाई मशीन से प्रेरित है। यह अभिनव उपकरण ब्रशों की घूर्णन शक्ति और सामग्रियों के बीच उत्पन्न घर्षण का लाभ उठाता है ताकि फलों और सब्जियों की सतहों पर चिपके हुए मिट्टी और अशुद्धियों को प्रभावी ढंग से समाप्त किया जा सके।

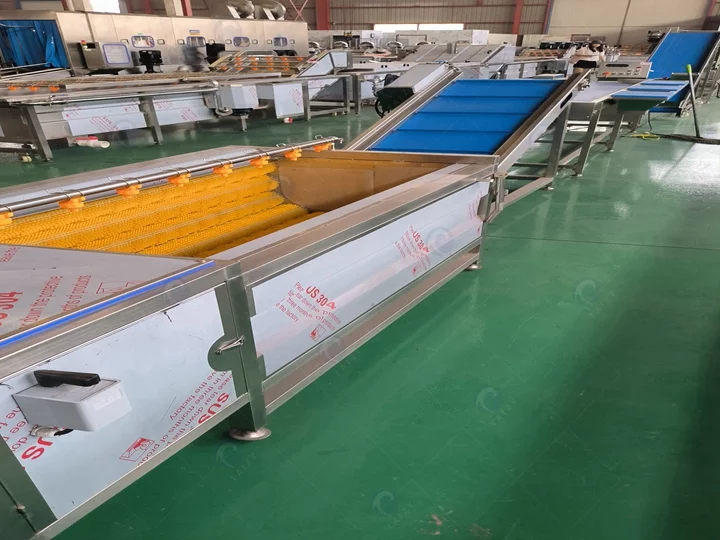

इस धोने की मशीन में स्टेनलेस स्टील का शरीर, ब्रश, मोटर, बेयरिंग, स्प्रे पाइप और इलेक्ट्रिक कंट्रोल बॉक्स जैसे आवश्यक घटक शामिल हैं, जो एक व्यापक सफाई प्रक्रिया सुनिश्चित करते हैं।

1. घूर्णन ब्रश सफाई

मशीन का परिचालन सार इलेक्ट्रिक मोटर द्वारा संचालित ब्रशों के घूर्णन में निहित है। जैसे-जैसे ये ब्रश घूर्णन करते हैं, वे फलों और सब्जियों की सतहों के साथ सीधे संपर्क में आते हैं, एक घर्षण प्रक्रिया शुरू करते हैं जो सतही गंदगी को हटा देती है। यह तंत्र एक संपूर्ण प्रारंभिक सफाई चरण सुनिश्चित करता है।

2. मिट्टी हटाने के लिए आपसी घर्षण

घूर्णन ब्रश और सामग्रियों के बीच आपसी घर्षण मशीन के कार्य का एक महत्वपूर्ण पहलू है। यह प्रक्रिया केवल घूर्णन से परे जाती है; यह घर्षण की शक्ति का लाभ उठाती है ताकि मिट्टी और अशुद्धियों को प्रभावी ढंग से अलग और समाप्त किया जा सके, जिससे फल और सब्जियाँ साफ और खाने के लिए तैयार हो जाती हैं।

3. स्टेनलेस स्टील की स्थायित्व

मुख्य रूप से स्टेनलेस स्टील से निर्मित, मशीन स्थायित्व और लचीलापन सुनिश्चित करती है। यह मजबूत निर्माण यह सुनिश्चित करता है कि उपकरण वाणिज्यिक रसोई और खाद्य प्रसंस्करण सेटिंग्स में दैनिक उपयोग की कठिनाइयों को सहन कर सके, दीर्घकालिक संचालन के लिए एक विश्वसनीय समाधान प्रदान करता है।

4. एकीकृत स्प्रे पाइप प्रणाली

सफाई प्रक्रिया को बढ़ाने के लिए, मशीन एक स्प्रे पाइप प्रणाली को एकीकृत करती है। जैसे-जैसे ब्रश घूर्णन करते हैं और सतहों को साफ करते हैं, स्प्रे पाइप पानी का वितरण करता है, एक अतिरिक्त सफाई तत्व प्रदान करता है। यह कदम न केवल ढीली अशुद्धियों को धोता है बल्कि फलों और सब्जियों की समग्र स्वच्छता और ताजगी में भी योगदान करता है।

5. सटीकता के लिए इलेक्ट्रिक नियंत्रण

इलेक्ट्रिक कंट्रोल बॉक्स संचालन का मस्तिष्क के रूप में कार्य करता है, मशीन के कार्यों पर सटीकता और नियंत्रण प्रदान करता है। ऑपरेटर आसानी से ब्रशों की घूर्णन गति को नियंत्रित कर सकते हैं और पानी के छिड़काव की प्रक्रिया का प्रबंधन कर सकते हैं, विभिन्न उत्पादों की विशिष्ट आवश्यकताओं के आधार पर अनुकूलित सफाई सुनिश्चित करते हैं।

6. व्यापक अशुद्धि हटाना

घूर्णन ब्रश सफाई को स्प्रे पाइप प्रणाली के साथ मिलाकर, यह मशीन एक व्यापक अशुद्धता हटाने की प्रक्रिया प्रदान करती है। यह प्रभावी रूप से सतही गंदगी का सामना करती है, जिसे ब्रश द्वारा संबोधित किया जाता है, और अशुद्धताओं को भी, जो दरारों या कठिनाई से पहुँचने वाले क्षेत्रों में फंसी हो सकती हैं, एक Thorough सफाई परिणाम की गारंटी देती है।

आधारभूत रूप से, सब्जियों और फलों की धोने और छीलने की मशीन के मुख्य कार्य घूर्णन ब्रश सफाई और आपसी घर्षण के कार्य सिद्धांत से जटिल रूप से जुड़े हुए हैं, जो विभिन्न पाक सेटिंग्स में फलों और सब्जियों की स्वच्छता और ताजगी सुनिश्चित करने के लिए एक विश्वसनीय, टिकाऊ और कुशल समाधान प्रदान करते हैं।