Machine à laver les œufs | Machine nettoyante pour œufs

| Modèle | TZ-100 |

| Capacité | 10000-14000pcs/h |

| Pouvoir | 1,5 kW |

| Tension | 380v |

| Taille | 2600*1630*1100mm |

Vous pouvez désormais demander des détails techniques à nos chefs de projets

La machine à laver les œufs est une solution haute performance qui peut nettoyer efficacement et de manière polyvalente, avec une capacité de traitement de 10 000 à 14 000 œufs par heure selon le modèle.

Construit en acier inoxydable durable, il garantit un nettoyage hygiénique de divers œufs, y compris les œufs de poule, de canard, d'oie et de caille, les laissant impeccables et brillants.

Disponible en plusieurs configurations telles que des modèles à une rangée, trois rangées et six rangées, cette machine répond aux divers besoins des clients tout en offrant des caractéristiques telles qu'un nettoyage approfondi, une grande vitesse et un traitement doux pour éviter les dommages.

Machine à laver les œufs à vendre

- Construction en acier inoxydable 304. Corps et roulements de chaîne durables et résistants à la corrosion garantissent une fiabilité à long terme.

- Brosse à rouleau en nylon haute résistance. Conçue pour une performance de nettoyage des œufs efficace et durable.

- Roue en caoutchouc d'alimentation des œufs Pom. Conçue pour un fonctionnement fluide et une durabilité prolongée, idéale pour une utilisation continue dans le traitement des œufs.

Pour répondre à différentes échelles de traitement, la machine est disponible en plusieurs modèles, y compris :

- Monorangée. Idéale pour les petites opérations.

- Trirangée. Convient pour un traitement à échelle moyenne.

- Six rangées. Conçue pour les besoins de traitement des œufs à grande échelle.

Pourquoi acheter la machine à laver les œufs ?

- Élimine la saleté, les contaminants et les bactéries. Améliore la sécurité alimentaire et l'hygiène.

- Nettoie automatiquement les œufs. Économise du temps et de la main-d'œuvre avec un fonctionnement simple du réservoir d'eau.

- Fabriqué avec des matériaux doux de qualité alimentaire. Minimise la casse des œufs pendant le processus de nettoyage.

- Fournit un nettoyage et un séchage uniformes. Garantit une apparence et une qualité cohérentes pour la présentation sur le marché.

- Augmente la valeur marchande. Des œufs propres et bien présentés peuvent commander de meilleurs prix.

- Système de tri intégré. Détecte et élimine les œufs défectueux, améliorant la qualité globale du produit.

Comment fonctionne la machine à laver les œufs ?

Chargement

Placez manuellement des paniers ou des boîtes entières d'œufs de poule ou de canard dans le réservoir d'eau.

Transport

Les œufs sont transportés sur des rouleaux de convoyeur, qui les déplacent systématiquement vers la zone de brossage.

Brossage

Les œufs passent à travers les rouleaux en poils, où ils sont soigneusement nettoyés par les brosses rotatives.

Décharge

Les œufs propres sont ensuite transportés vers l'extrémité de décharge de la machine.

Inspection

Les œufs défectueux sont retirés de la ligne.

Tri

Les œufs qualifiés sont transférés sur une bande transporteuse.

Traitement ultérieur

Selon les besoins, les œufs sont soit transportés vers une machine d'emballage, soit dirigés vers un séparateur automatique de jaune et de blanc d'œuf pour un traitement supplémentaire.

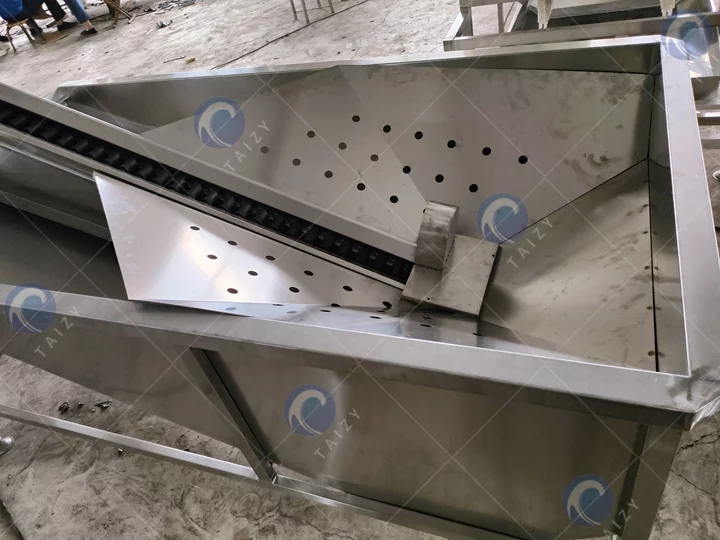

Principaux composants de la machine de nettoyage des œufs

- Réservoir d'eau. Fabriquée en acier inoxydable 304 pour la résistance à la corrosion, un nettoyage facile et la durabilité.

- Rack de transport des œufs. Construite en acier inoxydable 304, garantissant durabilité et résistance à la corrosion.

- Rouleaux de chargement des œufs. Des matériaux épais et résistants à la corrosion empêchent les dommages aux œufs et garantissent un chargement uniforme.

- Chaîne de chargement des œufs. Des maillons en acier inoxydable 304 épaissis offrent durabilité et empêchent la déformation.

- Brosses de nettoyage. Des brosses en fil torsadé résistantes à l'usure éliminent efficacement les taches de surface, tandis que l'axe de brosse en acier inoxydable résiste à la corrosion.

- Cadre. Disponible en designs de plaques d'acier pliées ou de tubes carrés ; les versions assemblées par module sont sans soudure et très durables.

- Inspection visuelle. La lumière froide LED permet des tests non destructifs et le retrait manuel des œufs défectueux.

- Tapis roulant. Fabriqué en PVC de qualité alimentaire pour un transport sûr et efficace des œufs.

La machine de nettoyage des œufs est très efficace avec un contrôle de vitesse à fréquence variable, capable de laver un certain nombre d'œufs par heure selon les spécifications de la machine. Les œufs traités sont propres, brillants et peuvent être facilement intégrés à d'autres équipements pour un traitement rationalisé.

Paramètres de la machine à laver les œufs

| Modèle | TZ-100 |

| Capacité | 10000-14000pcs/h |

| Tension | 380v |

| Pouvoir | 1,5 kW |

| Taille | 2600*1630*1100mm |

Équipements de soutien de la machine à laver les œufs

Notre machine à laver les œufs peut être améliorée avec plusieurs équipements de soutien pour optimiser davantage le flux de travail de traitement des œufs.

- stérilisateur UV. Cet appareil utilise la lumière ultraviolette pour éliminer efficacement les bactéries de surface sur les œufs, garantissant des normes d'hygiène et de sécurité plus élevées.

- Machine à classer les œufs. Cette machine trie les œufs selon leur poids, rationalisant le processus de classification et garantissant une qualité et une taille cohérentes pour l'emballage.

- machine à imprimer des œufs. Elle imprime des informations essentielles, telles que la date et les détails du fabricant, directement sur la surface de l'œuf. Cela fournit une traçabilité et un étiquetage importants pour le contrôle de la qualité et la conformité.

Ces ajouts complètent la machine à laver les œufs, offrant une solution complète pour nettoyer, trier et étiqueter les œufs de manière efficace.

Contactez-nous !

En choisissant notre machine à laver les œufs, vous investissez non seulement dans un équipement avancé et fiable, mais vous vous associez également à Taizy, une entreprise reconnue pour son expertise et son engagement envers la qualité dans l'industrie de la transformation alimentaire.

Nos machines sont conçues avec précision et construites pour durer, garantissant des performances optimales dans vos opérations. Avec des années d'expérience et un solide bilan de satisfaction client, nous sommes prêts à soutenir vos besoins commerciaux.

Contactez-nous aujourd'hui pour en savoir plus sur la façon dont notre machine à laver les œufs peut améliorer votre ligne de production et pour recevoir un devis personnalisé adapté à vos besoins.