Machine à séparer les blancs et les jaunes d'œufs | Machine à casser les œufs

| Capacité | 11 000~12 000 œufs/H |

| Taille | 1750*1200*1100 mm |

| Tension | 220V |

| Poids | 200 kg |

| Pouvoir | 0,4 kW |

Vous pouvez désormais demander des détails techniques à nos chefs de projets

La machine à séparer les blancs et les jaunes d'œufs entièrement automatique intègre un batteur à œufs automatique et une unité de séparation des blancs et des jaunes d'œufs, la rendant adaptée à la production de gâteaux, aux usines de poudre d'œufs et aux entreprises de production alimentaire traitant des produits à base d'œufs.

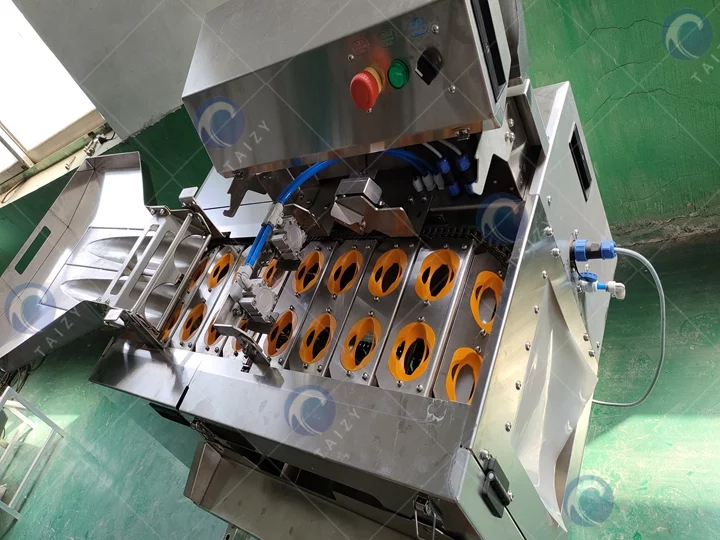

Disponible en configurations à deux, quatre et six rangées, la machine à casser les œufs a une capacité de production de 11 000 à 12 000 œufs par heure, s'adaptant aux besoins variés des clients. Fabriquée en acier inoxydable 304, la machine à séparer les œufs offre une excellente durabilité, sécurité et hygiène, la rendant idéale pour les cuisines commerciales et les industries de transformation alimentaire.

structure de la machine à séparer les blancs et les jaunes d'œufs

La structure de la machine de séparation des blancs et des jaunes d'œufs est fondamentale pour comprendre son fonctionnement et son efficacité. Explorons son design et ses composants clés.

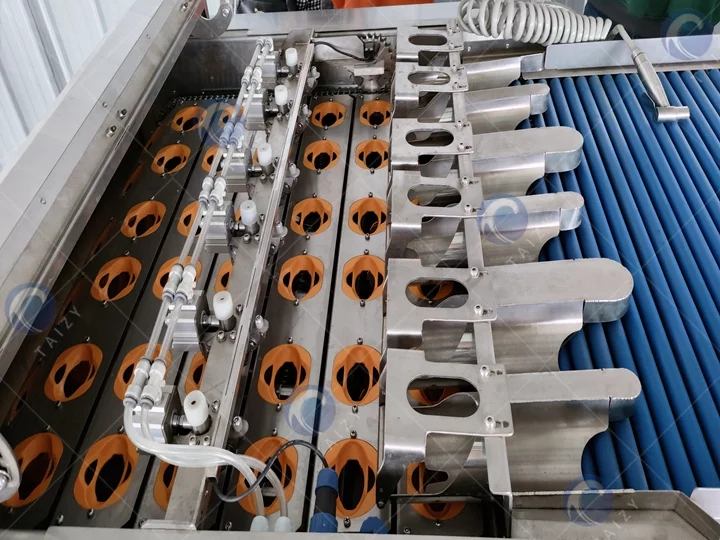

La machine à séparer les blancs et les jaunes d'œufs se compose d'un cadre, d'un système d'alimentation, d'un mécanisme de cassage de coquille et d'une unité de séparation des blancs et des jaunes d'œufs. Ensemble, ces composants garantissent un fonctionnement efficace, rendant la machine adaptée à la transformation des œufs à grande échelle.

Comment fonctionne la machine à casser les œufs ?

Avec une compréhension claire de la structure de la machine, nous pouvons maintenant plonger dans son processus opérationnel. La machine à casser les œufs fonctionne à travers plusieurs étapes, chacune jouant un rôle crucial dans la séparation précise des composants de l'œuf.

Chargement des œufs

Des œufs de poule ou de canard nettoyés sont placés séquentiellement dans les moules sur le tapis roulant.

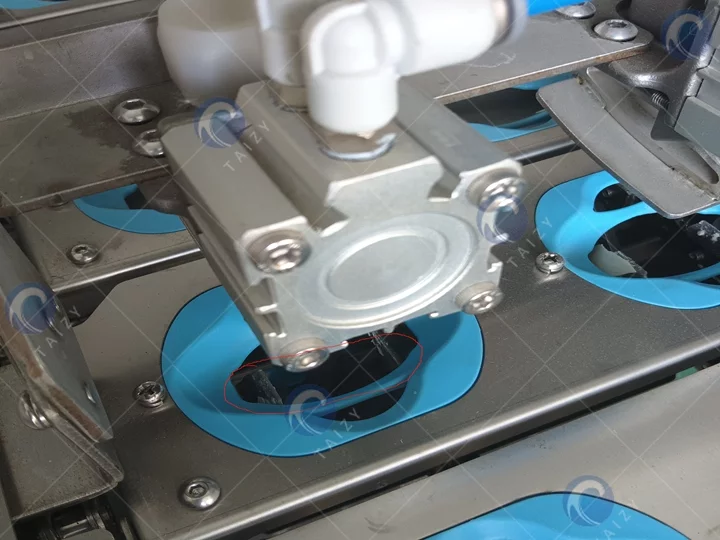

Cassage de la coquille

Au fur et à mesure que les œufs avancent le long du tapis roulant, ils atteignent la station de cassage de coquille où les coquilles d'œufs sont automatiquement ouvertes.

Séparation de la coquille

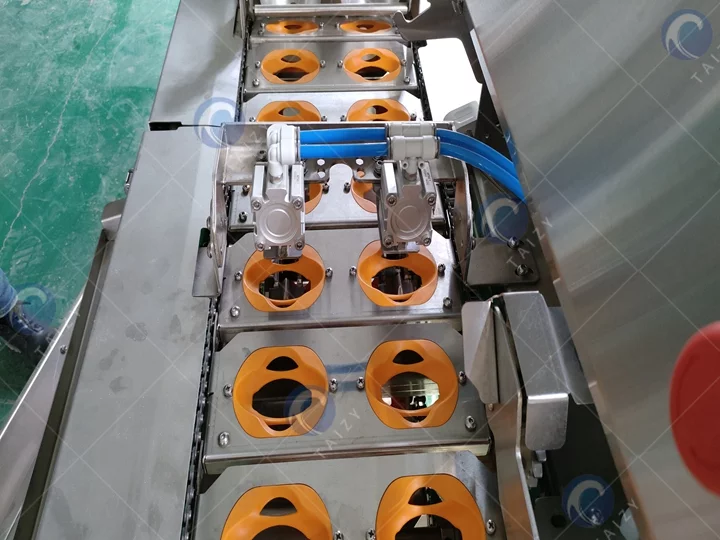

Sous le dispositif de serrage, les coquilles d'œufs sont fendues en deux moitiés à partir du point de cassage, permettant aux blancs et aux jaunes d'œufs de s'écouler.

Séparation

Les blancs et les jaunes d'œufs passent par l'unité de séparation, où les blancs d'œufs sont séparés et dirigés dans un conteneur, tandis que les jaunes d'œufs s'écoulent dans un autre conteneur.

Collecte des coquilles

Les coquilles d'œufs vides tombent dans un conteneur désigné pour un élimination ou un recyclage approprié.

Paramètres du séparateur de blancs et de jaunes d'œufs

Après avoir expliqué comment fonctionne la machine de séparation des blancs et des jaunes d'œufs, il est essentiel de comprendre les spécifications techniques. Ces paramètres mettent en évidence la capacité et les exigences opérationnelles de la machine.

| Tension | 220V |

| Dimensions | 1750*1200*1100 mm |

| Capacité de traitement | 11 000~12 000 œufs/H |

| Pouvoir | 0,4 kW |

| Poids | 200 kg |

Avantages de la machine à casser les œufs

Comprendre les paramètres de la machine nous permet d'apprécier ses divers avantages. Ces bénéfices soulignent pourquoi cette machine à casser les œufs est un ajout précieux à toute opération de transformation des œufs.

- Haute efficacité de séparation. Conçue pour une haute précision et rapidité dans la séparation des blancs et des jaunes d'œufs, optimisant le processus de séparation.

- Configurations multiples. Disponible en diverses configurations de rangées (par exemple, deux, quatre, six rangées) pour s'adapter à différentes échelles de production et capacités.

- Fonctionnement automatique. Un processus entièrement automatisé réduit le travail manuel, garantissant cohérence et fiabilité avec un minimum d'intervention humaine.

- Haute capacité. Capable de traiter 11 000 à 12 000 œufs par heure, adapté aux environnements de production à grande échelle.

- Gestion intégrée des coquilles : Inclut des mécanismes pour casser et collecter les coquilles d'œufs, rationalisant l'ensemble du flux de travail de transformation des œufs.

- Construction en acier inoxydable 304. Fabriqué avec de l'acier inoxydable de haute qualité pour la durabilité, la sécurité et un nettoyage facile, répondant aux normes d'hygiène dans le traitement des aliments.

Quel est le prix de la machine de séparation des blancs et des jaunes d'œufs ?

Maintenant que nous avons couvert la structure, le fonctionnement et les avantages de la machine, discutons de son prix. Le coût de la machine à séparer les blancs et les jaunes d'œufs est influencé par plusieurs facteurs.

Le prix d'une machine à séparer les blancs et les jaunes d'œufs peut varier en fonction de facteurs tels que la capacité de la machine, la distance d'expédition et d'autres considérations. Le prix final sera également influencé par les spécifications de l'équipement et le volume de commande. Nous fournissons des devis précis adaptés à vos besoins et configurations spécifiques.

De plus, nous prenons en compte le coût de maintenance et le service après-vente pour garantir que l'équipement que vous achetez est non seulement à un prix raisonnable mais aussi fiable et bien adapté à vos exigences de production. Si vous avez des questions ou avez besoin de plus d'informations, n'hésitez pas à nous contacter. Nous sommes là pour vous aider.

Questions fréquentes sur la machine à casser les œufs

Pour répondre à toutes les questions restantes, nous avons compilé une liste de questions fréquemment posées. Ces FAQ fournissent des informations supplémentaires sur le fonctionnement et l'entretien de la machine à casser les œufs.

Comment la machine garantit-elle une séparation précise des blancs et des jaunes d'œufs ?

La machine utilise une technologie de séparation avancée qui distingue précisément les blancs et les jaunes d'œufs. Elle emploie une combinaison de systèmes mécaniques et basés sur des capteurs pour réaliser une séparation précise et efficace.

Quel est le calendrier de maintenance recommandé pour la machine ?

Un entretien régulier est essentiel pour garantir des performances optimales. Il est recommandé de nettoyer la machine après chaque utilisation et de procéder à une inspection et un entretien approfondis tous les 3 à 6 mois, selon la fréquence d'utilisation.

La machine peut-elle gérer des tailles d'œufs différentes ?

Oui, la machine est conçue pour s'adapter à différentes tailles d'œufs. Elle peut être ajustée pour traiter efficacement à la fois des petits et des gros œufs, garantissant ainsi une polyvalence dans le traitement des œufs.

Quel soutien est disponible si la machine rencontre des problèmes ?

Nous fournissons un support complet, y compris une assistance technique, un dépannage et des services de réparation. Notre équipe de service client est disponible pour résoudre tout problème et garantir le bon fonctionnement de la machine.

Laissez votre message !

En résumé, notre machine à séparer le blanc et le jaune d'œuf est conçue pour offrir une efficacité, une précision et une fiabilité élevées pour vos besoins de traitement des œufs. Avec ses caractéristiques avancées et sa construction durable, elle garantit une séparation optimale des blancs et des jaunes d'œufs, répondant aux exigences des environnements de production à grande échelle.

Pour une solution complète de traitement des œufs, nous proposons également des machines de tri des œufs qui peuvent être utilisées en conjonction avec notre séparateur pour rationaliser l'ensemble de votre ligne de production. Si vous avez des questions ou avez besoin de plus d'informations sur nos produits, n'hésitez pas à nous contacter.