Máquina para hacer hamburguesas

| Modelo | TZ-HB-400 |

| Fuerza | 1,1 kw |

| Tamaño | 2828*830*2136mm |

| Capacidad | 200-600kg/hora |

| Espesor de producción | 6-25 mm |

Ahora puede solicitar detalles técnicos a nuestros jefes de proyecto

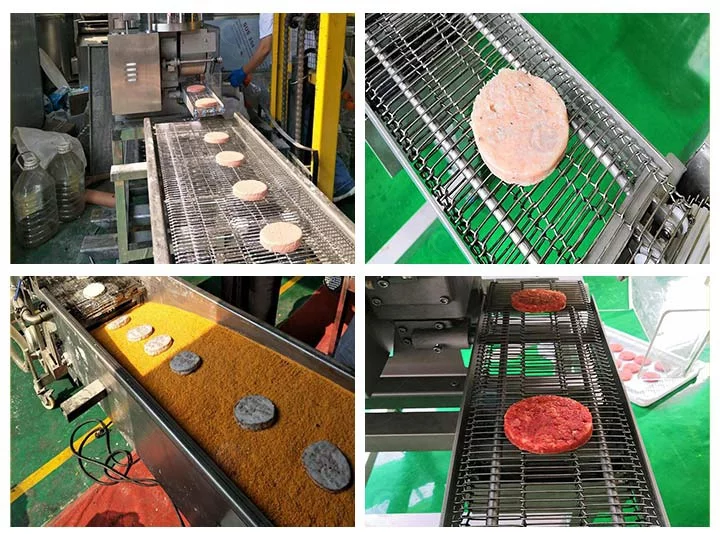

La máquina para hacer hamburguesas se utiliza para crear hamburguesas de forma y tamaño uniformes. Generalmente está hecha de aluminio o acero inoxidable y consta de dos partes: una base y una prensa superior. La base tiene una hendidura poco profunda en el centro, mientras que la prensa superior tiene un émbolo elevado que encaja perfectamente en la hendidura.

Las máquinas para hacer hamburguesas están disponibles en varios tamaños, lo que permite a los clientes seleccionar la que produzca hamburguesas del tamaño ideal para requisitos específicos. Ciertos modelos también ofrecen funcionalidades adicionales como grosor y forma de hamburguesa personalizables.

¿Qué materias primas son adecuadas para la máquina de hacer hamburguesas?

La máquina para hacer hamburguesas es altamente versátil y compatible con una amplia gama de materias primas. Puede procesar varios tipos de carne como pollo, res, cordero y cerdo. También es perfecta para formar productos de mariscos como pescado, camarones, calamares y salmón en hamburguesas uniformes.

Además de los ingredientes de origen animal, esta máquina puede manejar una variedad de opciones a base de plantas. Ingredientes como papas, batatas, calabazas, zanahorias, judías verdes, frijoles rojos, frijoles anchos y soya se pueden usar para hacer hamburguesas vegetales nutritivas. Para mejorar el sabor y el equilibrio nutricional, estas verduras se pueden mezclar con carne o mariscos para crear hamburguesas mezcladas.

Todas estas hamburguesas procesadas se pueden utilizar directamente en la producción de hamburguesas, lo que hace que la máquina sea ideal para procesadores de carne, proveedores de comida rápida y fabricantes de productos vegetarianos.

¿Cómo funciona la máquina para formar hamburguesas?

- Instale el molde de formación

- Adjunte el molde de tambor de carne deseado según la forma y tamaño requeridos.

- Abra el barril de material

- Levante la tapa de la tolva para preparar la adición del relleno de carne.

- Instale la paleta de prensado de carne

- Coloque la paleta de prensado dentro del barril para ayudar a guiar la carne durante la operación.

- Agregue el relleno de carne

- Llene el barril con la mezcla de carne preparada, que puede incluir carne, mariscos o mezclas de vegetales.

- Inicie la máquina

- Encienda la máquina de hacer hamburguesas para iniciar el proceso de moldeo.

- La cuchilla de prensado de carne gira

- La cuchilla gira dentro del barril, presionando continuamente la carne en el molde de formación.

- Formación y corte

- El molde se llena y da forma, luego un alambre de acero corta la hamburguesa y la mueve a la cinta transportadora.

- Salida continua

- El proceso se repite automáticamente, produciendo hamburguesas en un ciclo consistente y eficiente.

Características clave de la máquina para hacer hamburguesas

- Forma y tamaño uniforme de la hamburguesa para una presentación profesional.

- Grosor ajustable para satisfacer diferentes necesidades del cliente.

- Salida rápida y eficiente, ideal para uso comercial.

- Soporta diversas carnes y verduras incluyendo carne de res, pollo, pescado y mezclas a base de plantas.

- Cuerpo de acero inoxidable, higiénico y fácil de limpiar.

- Diseño duradero y seguro para una operación a largo plazo sin preocupaciones.

Moldes personalizados de máquina para hacer hamburguesas

- Múltiples opciones de forma. Soporta moldes en forma de círculo, triángulo, rectángulo, corazón y formas especiales.

- Diferenciación de marca. Moldes personalizados ayudan a crear apariencias de productos únicas para atraer al mercado.

- Aplicaciones flexibles. Adecuado para carne, mariscos, verduras o rellenos mixtos.

- Integración sin costuras. Funciona con picadora de carne para una línea de procesamiento completa.

- Listo para varios procesamientos. Las hamburguesas formadas pueden ser fritas, congeladas o envasadas al vacío.

- Producción eficiente. Reemplaza la mano de obra manual, acelera la formación y la salida.

Parámetros técnicos de la máquina para hacer hamburguesas.

| Modelo | TZ-HB-400 |

| Tamaño | 2828*830*2136mm |

| Capacidad | 200-600kg/hora |

| Peso | 100 kilos |

| Fuerza | 1,1 kw |

| Espesor de producción | 6-25 mm |

¿Por qué elegir comprar nuestra máquina para hacer hamburguesas?

Esta máquina para hacer hamburguesas combina versatilidad, precisión y eficiencia para satisfacer las demandas de la producción moderna de alimentos. Desde la personalización de formas hasta la operación optimizada, te permite ofrecer calidad constante con cada hamburguesa.

Si está buscando aumentar la productividad y mejorar el atractivo del producto, esta máquina es una inversión inteligente. ¡No dude en contactarnos para soluciones personalizadas y soporte experto!