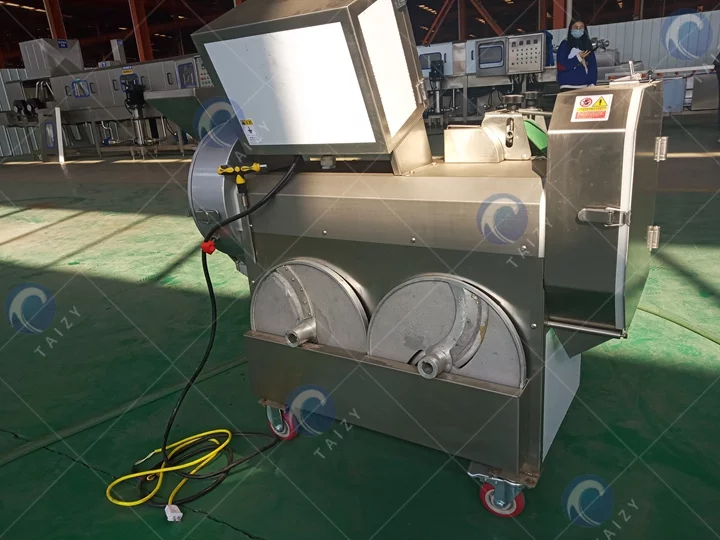

Máquina cortadora de verduras de doble cabeza

| Capacidad | 600~1000 kg/h |

| Fuerza | 1370W |

| Voltaje | 220/380V |

| Tamaño | 1100*600*1200mm |

| Peso | 145KG |

Ahora puede solicitar detalles técnicos a nuestros jefes de proyecto

La máquina cortadora de verduras de doble cabeza es la solución definitiva para tus necesidades de procesamiento de verduras. Esta innovadora máquina cuenta con dos tipos de aberturas de corte: una adaptada para verduras de raíz y la otra para hojas verdes. Lo que nos distingue es la operación simultánea de estas dos aberturas, mejorando significativamente la eficiencia de producción.

Además, nuestra máquina permite tamaños de corte ajustables, proporcionando una flexibilidad y opciones de personalización inigualables para satisfacer tus requisitos específicos. Esto convierte a nuestra máquina en un activo indispensable en tu línea de procesamiento, ahorrándote tiempo y costos mientras asegura productos de alta calidad de manera consistente.

Estructura de la máquina cortadora de verduras de doble cabeza

La máquina cortadora de verduras de doble cabeza presenta una estructura optimizada diseñada para una eficiencia óptima en el procesamiento de verduras. Incluye dos puertos de alimentación para verduras de raíz, un puerto de alimentación para verduras de hoja, cintas de presión para verduras, cintas transportadoras, puertos de descarga y una caja de control eléctrico.

Con puertos dedicados para verduras de raíz y de hoja, la máquina se integra perfectamente en las líneas de producción, permitiendo un procesamiento simultáneo sin ajustes frecuentes. Las cintas de presión y las cintas transportadoras regulan el flujo de verduras, asegurando un corte uniforme y un desperdicio mínimo.

Los puertos de descarga permiten la recolección eficiente de verduras procesadas, mientras que la caja de control eléctrico proporciona un control de operación intuitivo. En general, esta estructura destaca la fiabilidad, versatilidad y capacidad de la máquina para satisfacer diversas necesidades de procesamiento.

¿Cómo funciona la máquina cortadora de verduras?

1. Alimentacióng

Las verduras se cargan en la máquina a través de puertos de alimentación designados. Estos puertos suelen estar diseñados para acomodar diferentes tipos y tamaños de verduras.

2. Transporte

Una vez dentro de la máquina, las verduras son guiadas a lo largo de cintas transportadoras. Estas cintas aseguran un flujo constante de verduras a través del proceso de corte.

3. Mecanismo de corte

El mecanismo de corte de la máquina varía dependiendo del resultado deseado.

4. Ajuste

Los operadores pueden ajustar el mecanismo de corte para lograr tamaños o estilos de corte específicos según los requisitos de la receta o de la línea de producción.

5. Procesamiento

A medida que las verduras pasan a través del mecanismo de corte, son rebanadas, picadas, ralladas o procesadas de otra manera en las formas y tamaños deseados.

6. Descarga

Las verduras procesadas salen de la máquina a través de puertos de descarga, donde se recogen para un procesamiento o empaquetado adicional.

7. Control

La máquina está equipada con un panel de control o interfaz que permite a los operadores monitorear y ajustar varias configuraciones, como la velocidad de corte, el tamaño de corte y las características de seguridad.

Principales ventajas de la máquina cortadora de doble cabeza

- Procesamiento simultáneo: La capacidad de operar dos cabezales de corte simultáneamente distingue a esta máquina. Permite el procesamiento paralelo de diferentes tipos de verduras sin sacrificar la eficiencia, duplicando así la producción en comparación con las máquinas de un solo cabezal.

- Puertos de corte dedicados: Con puertos separados para verduras de raíz y hojas verdes, esta máquina ofrece un procesamiento especializado para cada tipo de verdura. Esto asegura un rendimiento de corte optimizado y calidad del producto adaptada a tipos de productos específicos.

- Tamaños de corte ajustables: La capacidad de la máquina para ajustar los tamaños de corte según necesidades específicas proporciona una flexibilidad inigualable. Los operadores pueden personalizar fácilmente las especificaciones de corte, adaptándose a diversas recetas o preferencias del cliente sin comprometer la eficiencia.

- Flujo de trabajo optimizado: Al acomodar dos tipos de verduras simultáneamente y ofrecer tamaños de corte ajustables, esta máquina optimiza el flujo de trabajo y minimiza el tiempo de inactividad para ajustes. Asegura un proceso de producción fluido y eficiente, mejorando la productividad general.

En esencia, las ventajas únicas de la máquina de corte de doble cabeza radican en su capacidad de procesamiento simultáneo, puertos de corte especializados, tamaños de corte ajustables y flujo de trabajo optimizado, lo que la convierte en una solución altamente eficiente y versátil para las operaciones de procesamiento de verduras.

Parámetros de la máquina cortadora de verduras multifuncional

- Voltaje: 220/380V

- Potencia: 1370W

- Peso Neto: 145KG

- Dimensiones: 1100*600*1200mm

- Capacidad: 600~1000kg/h

- Tamaño de corte de verduras de hoja: Ajustable de 1 a 60mm.

- Verdura de raíz Corte: 2-10mm

- Rallado de verduras bulbosas: 2-10mm

- Corte de verduras bulbosas: 8mm, 10mm, 12mm, 15mm, 20mm

Conclusión

Nuestra máquina cortadora de verduras de doble cabeza es su elección ideal para mejorar la productividad y optimizar el flujo de trabajo. Su excepcional rendimiento y flexibilidad le permiten satisfacer sin esfuerzo diversas necesidades de procesamiento de verduras, asegurando la calidad del producto y la eficiencia de producción mientras ahorra costos y tiempo.

Además de nuestra máquina cortadora de doble cabeza, también ofrecemos modelos estándar de máquinas cortadoras de verduras a precios más competitivos, igualmente confiables y duraderas. Te invitamos a seleccionar el producto más adecuado según tus requisitos específicos, con nuestro equipo listo para proporcionar consulta y apoyo. ¡Contáctanos ahora para solicitar un presupuesto y trabajemos juntos para alcanzar tus objetivos de producción!