Máquina de congelación rápida | Máquina de congelación instantánea

| Modelo | TZ-C7 |

| Tamaño | 880*900*1850mm |

| Fuerza | 1200w |

| Voltaje | 220v |

| Bandejas | 7 |

| Volumen | 120L |

Ahora puede solicitar detalles técnicos a nuestros jefes de proyecto

Las máquinas de congelación rápida, también conocidas como máquinas de congelación instantánea, congelan rápidamente los alimentos para preservar la calidad, la textura y el valor nutricional minimizando la formación de cristales de hielo. Esenciales en la industria alimentaria, congelan eficientemente grandes cantidades de mariscos, carnes, frutas, verduras y comidas listas para comer.

Las máquinas de congelación rápida tienen rangos de temperatura ajustables de 0 a -45 grados Celsius, acomodando diversas necesidades de congelación. Cada bandeja puede contener hasta 6 kilogramos de alimentos, con tiempos de trabajo típicos de 60 a 90 minutos, mejorando la eficiencia y reduciendo el tiempo de congelación. Esto las hace invaluables para extender la vida útil, reducir el desperdicio y garantizar la seguridad y calidad de los alimentos.

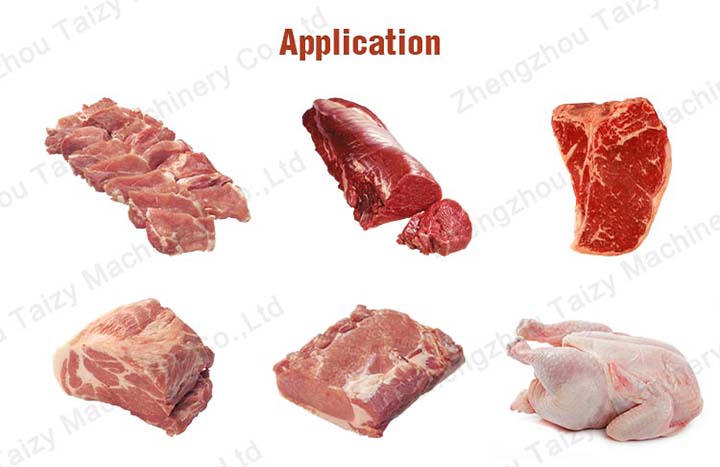

Aplicación de la máquina de congelación rápida

Industria alimentaria

- Mariscos. Asegura frescura y previene el deterioro al congelar rápidamente pescados y mariscos, manteniendo su sabor y textura.

- Carnes. Utilizada para congelar carne de res, aves y cerdo, extendiendo la vida útil y reduciendo el riesgo de quemaduras por congelación.

- Frutas y verduras. Preserva el valor nutricional, el sabor y la textura de las frutas y verduras para su uso en períodos fuera de temporada.

- Comidas listas para comer. Esencial para congelar comidas precocinadas y alimentos convenientes, asegurando almacenamiento a largo plazo sin comprometer la calidad.

Productos de panadería

- Masa y pasteles. Congela rápidamente productos de masa y pastelería para mantener su frescura y asegurar consistencia en la cocción.

Productos lácteos

- Helados y postres congelados. Utilizada en la producción de helados y postres congelados para congelar rápidamente la mezcla, previniendo la formación de grandes cristales de hielo y asegurando una textura suave.

Industria farmacéutica

- Almacenamiento de vacunas. Importante para la preservación de vacunas y otros productos farmacéuticos sensibles a la temperatura, asegurando su eficacia y seguridad.

Biotecnología

- Preservación celular. Utilizada para la preservación de muestras biológicas, incluyendo células, tejidos y enzimas, para aplicaciones de investigación y médicas.

Agricultura

- Preservación de semillas. Utilizada para congelar semillas agrícolas, extendiendo su viabilidad y asegurando una germinación exitosa.

Procesamiento de alimentos

- blanquear. La congelación rápida se utiliza para enfriar rápidamente verduras blanqueadas antes del envasado, manteniendo el color y la textura.

Ventajas clave de la máquina de congelación instantánea

- Alta eficiencia energética. Utiliza compresores importados conocidos por su uso eficiente de energía, a pesar de niveles de ruido más altos, asegurando un enfriamiento y congelación rápidos.

- Tecnología de descongelación eléctrica. Mejora la seguridad y ahorra electricidad en comparación con métodos tradicionales, reduciendo costos operativos y necesidades de mantenimiento.

- Sistema de control de temperatura por microcomputadora. Permite una regulación precisa de la temperatura dentro de los rangos permitidos, optimizando las condiciones de congelación para diferentes tipos de alimentos para mantener la calidad.

- Capacidad de congelación rápida. Permite la congelación rápida de artículos alimenticios, preservando frescura, textura y valor nutricional mientras se extiende la vida útil.

Parámetros de la máquina de congelación rápida

| Modelo | Bandejas | Tamaño (mm) | Potencia total | Volumen (L) | Voltaje (V) | Rango de temperatura (°C) | Espaciado de estantes (mm) | Método de refrigeración |

| TZ-C5 | 5 | 880*900*1270 | 1.5P, 1200W | 120 | 220 | 0~-45 | 80 | Refrigeración por aire |

| TZ-C7 | 7 | 880*900*1850 | 1.5P, 1200W | 120 | 220 | 0~-45 | 80 | Refrigeración por aire |

| TZ-C10 | 10 | 880*900*1850 | 2P, 1500W | 300 | 220 | 0~-45 | 80 | Refrigeración por aire |

| TZ-C12 | 12 | 880*900*1850 | 2P, 1500W | 300 | 220 | 0~-45 | 80 | Refrigeración por aire |

Por qué elegir nuestra congelación rápida congelación máquina

Nuestras máquinas de congelación rápida están diseñadas para ofrecer un rendimiento confiable, respaldadas por asistencia en línea las 24 horas y servicios de mantenimiento de por vida. Cada máquina viene con manuales en inglés y videos instructivos, asegurando una operación sencilla.

Se realizan rigurosos controles de calidad en todos los componentes, incluyendo marcos de acero inoxidable, tornillos y rodamientos, para mantener los estándares de la industria. Antes del envío, se realizan pruebas extensivas y documentación en video que valida la integridad operativa de las máquinas a su llegada.

En caso de cualquier problema operativo, nuestra generosa garantía de un año asegura una pronta resolución. Los clientes pueden acelerar los diagnósticos proporcionando videos de retroalimentación y facilitando soluciones rápidas. Para problemas derivados de un funcionamiento inadecuado, las piezas están disponibles a costo, mientras que los defectos de fabricación se rectifican con reemplazos gratuitos.

Nuestro dedicado equipo de soporte técnico está listo para ayudar con el reemplazo de piezas y procedimientos de mantenimiento, asegurando una operación sin problemas.

Invierta en nuestra máquina de congelación rápida

Nuestras máquinas de congelación rápida son altamente eficientes y tecnológicamente avanzadas. Aseguran la calidad y frescura de los alimentos. Estas máquinas brindan soporte confiable y soluciones optimizadas para sus operaciones comerciales. ¡Contáctenos ahora para obtener información detallada y precios!

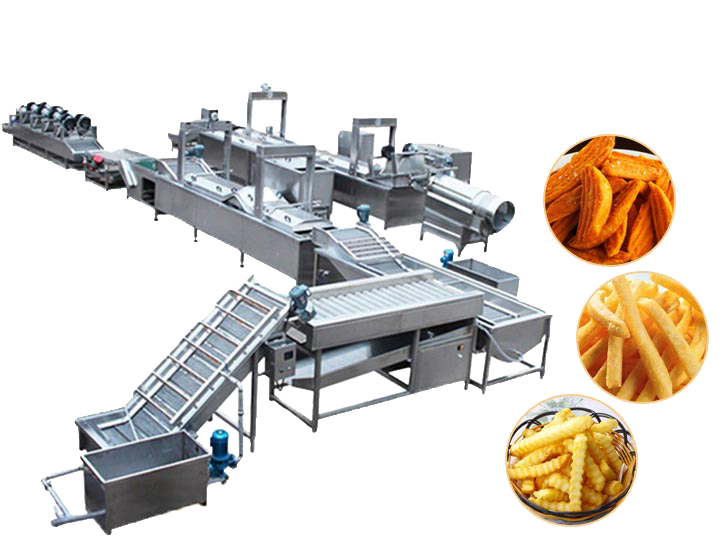

Además, nuestras máquinas de congelación rápida pueden integrarse sin problemas con líneas de producción de papas fritas, líneas de procesamiento de patas de pollo, o maquinaria de procesamiento de carne, ofreciendo sinergia integral para sus líneas de producción.