Máquina de fazer biscoitos|Depósito de biscoitos

| Modelo | TZ-400 |

| Poder | 1,5 kW |

| Tensão | 220V/50HZ |

| Capacidade | 100-180kg/h |

| Peso | 500KG |

Agora você pode pedir detalhes técnicos aos nossos gerentes de projeto

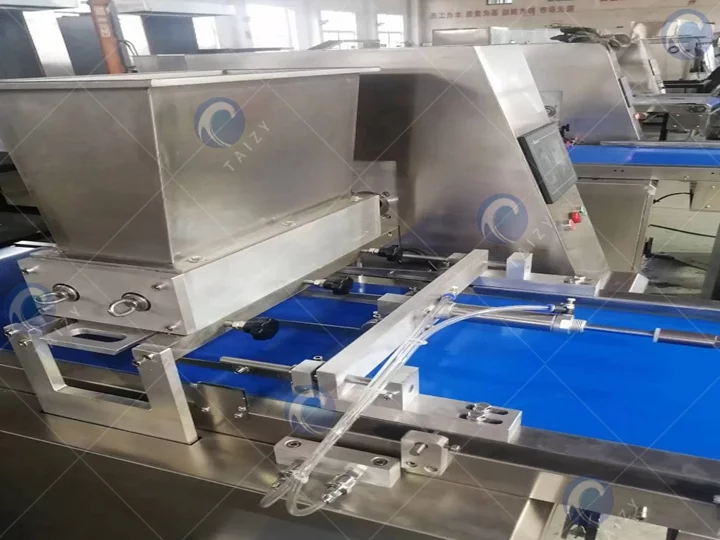

A Máquina de Fazer Biscoitos é um dispositivo único que extruda massa em várias formas para produzir biscoitos. Ao simplesmente trocar diferentes moldes, esta máquina pode criar biscoitos de diferentes formas, dando-lhes aparências únicas e atraentes. Os biscoitos feitos pela Máquina de Fazer Biscoitos têm formas especiais, padrões limpos e designs bonitos.

Além disso, a Máquina de Fazer Biscoitos pode ser emparelhada com um forno para assar os biscoitos após serem moldados. Esta linha de produção completa aumenta significativamente a eficiência da produção de biscoitos.

Compacta e automatizada, a Máquina de Fazer Biscoitos é adequada tanto para pequenas quanto para grandes fábricas de biscoitos. Ela oferece versatilidade e eficiência, tornando-se a escolha perfeita para produzir uma ampla variedade de biscoitos deliciosos.

No reino da produção de biscoitos, oferecemos três tipos diferentes de máquinas para fazer biscoitos: modelo PLC, modelo mecânico e modelo manual. Essas máquinas podem ajudá-lo a produzir biscoitos de várias formas, aparência bonita e sabor rico para atender às necessidades de diferentes clientes. Vamos dar uma olhada nas características e vantagens de cada tipo de máquina de fazer biscoitos.

1. Modelo PLC Máquina de Biscoitos:

Entre nossa gama de máquinas para fazer biscoitos, o modelo PLC se destaca como uma das opções mais avançadas disponíveis. Este modelo é capaz de produzir biscoitos macios e duros. Biscoitos macios são feitos extrudindo a massa através de rolos, enquanto biscoitos duros são cortados com um cortador de fio.

Equipado com uma tela PLC avançada, esta máquina permite controle preciso sobre o volume de extrusão, método de torção, velocidade e mais, garantindo formas e qualidade consistentes dos biscoitos.

2. Modelo Mecânico Fabricante de Biscoitos:

Além do modelo PLC, também oferecemos um modelo mecânico de máquina de fazer biscoitos. A principal diferença está no sistema de controle. Ao contrário do modelo PLC, o modelo mecânico não possui uma tela para controle.

Ajustes precisam ser feitos manualmente, o que pode ser um pouco menos conveniente e preciso em comparação com o modelo PLC. No entanto, ainda oferece desempenho confiável e é adequado para produção em menor escala.

3. Modelo Manual Máquina de Fazer Biscoitos:

Além dos modelos automáticos PLC e mecânico, também oferecemos um modelo manual de máquina de fazer biscoitos. Esta máquina semi-automática possui um pedal para extrusão e requer operação manual para avanço e recuperação da bandeja.

Equipado com um bico de extrusão de cobre e outros componentes feitos de aço inoxidável 201, esta máquina oferece funcionalidade básica para fazer biscoitos. Além disso, vem com 27 conjuntos de bicos intercambiáveis, permitindo que os clientes escolham de acordo com suas necessidades específicas.

Se você precisa do controle preciso oferecido pelo modelo PLC, da confiabilidade mecânica do modelo mecânico ou da funcionalidade básica fornecida pelo modelo manual, nossa gama de máquinas para fazer biscoitos atende a várias necessidades e preferências de produção.

A máquina formadora de biscoitos é projetada para facilidade de operação, exigindo apenas uma pessoa para controlar todo o processo. Sua ampla gama de aplicações a torna incrivelmente versátil. Ela pode produzir eficientemente vários tipos de biscoitos, incluindo biscoitos Jenny, biscoitos tradicionais, bolos inteiros, macarons, puffs, palitos de gergelim, bolos de algas, bolos de gergelim, bolos de gema de ovo e muito mais.

Equipado com um sistema de controle PLC de motor servo avançado, o depositador de biscoitos garante saída de produto precisa e consistente. Cada extrusora de massa produz biscoitos do mesmo tamanho e forma, garantindo uniformidade e qualidade em todos os lotes.

Esta máquina possui tecnologia avançada, oferecendo controle de peso preciso, operação simplificada e um preço competitivo. Além disso, pode ser integrada perfeitamente em uma linha de produção de biscoitos, trabalhando em conjunto com um misturador de massa, máquina de assar e outros equipamentos para otimizar o processo de produção.

Recentemente completámos um caso de sucesso da nossa máquina de formar biscoitos nos Estados Unidos. O nosso cliente, uma nova empresa de fabricação de biscoitos, precisava de uma máquina eficiente capaz de produzir vários tipos de biscoitos. Recomendámos a nossa máquina de formar biscoitos, conhecida pela sua facilidade de operação e versatilidade.

Equipado com um avançado sistema de controle PLC com motor servo, nossa máquina garante controle preciso de peso e qualidade consistente do produto. O cliente ficou altamente satisfeito com o desempenho da máquina, que melhorou significativamente sua eficiência de produção e qualidade do produto.

Este caso de sucesso demonstra ainda mais a experiência da nossa empresa em equipamentos de produção de biscoitos e fortalece nossa posição no mercado dos EUA.

Parâmetros do depósito de biscoitos

| Modelo | TZ-400 |

| Poder | 1,5 kW |

| Pressão de ar | 5-6kg/m³ |

| Tensão | 220V/50HZ |

| Capacidade | 100-180kg/h |

| tamanho da forma de assar | 600*400mm |

| tamanho do equipamento | 1460*960*1240mm |

| Peso | 500KG |

Invista em nossa máquina de fazer biscoitos

Ao introduzir nossa máquina de fazer biscoitos, você não apenas aumenta a eficiência da produção, mas também reduz os custos de produção enquanto melhora a qualidade do produto. Estamos comprometidos em fornecer a você a tecnologia e os equipamentos mais avançados para atender às demandas de um mercado em constante mudança.

Escolha nossa máquina de fazer biscoitos para tornar seu processo de produção de biscoitos mais inteligente, eficiente e sustentável, mantendo assim uma posição de liderança no mercado competitivo. Entre em contato conosco agora para saber mais sobre como nossa máquina de fazer biscoitos pode ajudá-lo a elevar seu nível de produção!