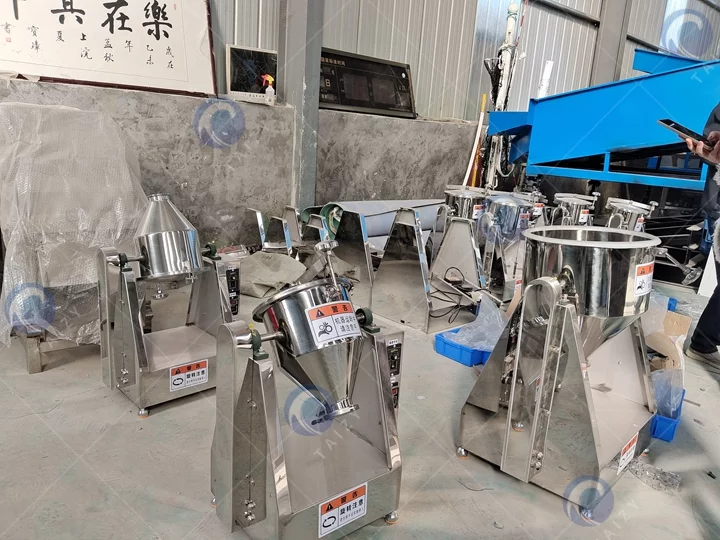

machine à mélanger les poudres

| Modèle | GH100-B |

| Taille | 1200*815*1200mm |

| Capacité | 180L |

| Vitesse du tambour | 28tr/min |

| Vitesse de l'arbre principal | 40-41tr/min |

| Pouvoir | 380V 4 pôles 3KW |

Vous pouvez désormais demander des détails techniques à nos chefs de projets

La machine à mélanger en poudre est conçue pour un mélange efficace et uniforme, disponible en configurations en forme de U et de tambour. Elle est largement utilisée pour mélanger des poudres d'assaisonnement, des poudres de thé au lait, des poudres de café et d'autres matériaux fins. Avec une vitesse de mélange réglable, elle assure un contrôle précis de la consistance du mélange.

La machine est construite avec de l'acier inoxydable 304 pour les parties en contact avec le matériau et de l'acier inoxydable 201 pour le cadre, garantissant durabilité et hygiène. Offrant une plage de capacité de 60L à 490L, notre mélangeur en poudre a été exporté avec succès en Australie, aux États-Unis et au Pérou, prouvant sa fiabilité dans diverses industries.

Comment choisir la machine à mélanger les poudres appropriée ?

Lors du choix d'une machine à mélanger en poudre, le choix entre un mélangeur en forme de U et un mélangeur à tambour dépend de plusieurs facteurs, y compris la finesse de la poudre, la capacité de production et les exigences d'emballage de transport.

1. Finesse de la poudre

- Mixeur à U-trough. Idéal pour les matériaux nécessitant un degré de finesse plus élevé. La conception en U permet un mélange plus intensif, ce qui le rend adapté aux poudres fines telles que les épices, la poudre de thé et la poudre de café. Le mélangeur en U garantit un mélange homogène avec une variation minimale de la taille des particules.

- Mixeur à tambour. Convient aux matériaux qui ne nécessitent pas un mélange extrêmement fin. Le mélangeur à tambour fournit une action de mélange douce, ce qui le rend idéal pour les poudres moins sensibles à la taille des particules, telles que certains types d'aliments pour animaux ou de matériaux industriels.

2. Capacité de production

- Mixeur à U-trough. Disponible en plus grandes capacités, le plus petit modèle capable de traiter 100 kg par lot. Les mélangeurs en U sont adaptés à la production de moyenne à grande échelle, avec des capacités allant de 100 kg à 1000 kg.

- Mixeur à tambour. Typically has a smaller capacity range, suitable for small to medium-scale production. Drum mixers can handle batches ranging from 2kg to 300kg, making them ideal for operations that require flexibility in batch sizes.

3. Transport et emballage

- Mixeur à U-trough. The U-trough design allows for easier cleaning and maintenance, which is beneficial for operations that require frequent changes in packaging materials. The mixer’s design also ensures minimal residue, making it easier to package the final product.

- Mixeur à tambour. The drum mixer’s compact design makes it easier to transport and install in various locations. This is particularly useful for operations that require mobile mixing solutions or have space constraints.

Considérations spéciales

- Mixeur à U-trough. Recommended for applications where the powder’s fineness and homogeneity are critical, such as in the food and pharmaceutical industries. The U-trough mixer’s ability to handle larger batches also makes it suitable for high-volume production.

- Mixeur à tambour. Ideal for operations that require gentle mixing and have lower capacity needs. The drum mixer’s simplicity and ease of use make it a cost-effective solution for small to medium-scale production.

Lors du choix entre un mélangeur en forme de U et un mélangeur à tambour pour votre machine à mélanger en poudre, considérez les exigences spécifiques de votre application, y compris la finesse désirée de la poudre, la capacité de production et les besoins de transport.

Pour une production à volume élevé et des exigences de poudre fine, le mélangeur en forme de U est le choix recommandé. Pour des lots plus petits et des besoins de mélange doux, le mélangeur à tambour est une excellente option.

Paramètres de la machine à mélanger les poudres à tambour

| Modèle | Taille externe (mm) | Taille du tambour (mm) | Capacité (L) | Alimentation électrique | Taille du port de décharge | Vitesse du tambour (tr/min) | Vitesse de l'arbre principal (tr/min) |

| GH30-B | 940*630*1000 | 390*710 | 60 | 220V 4 pôles 2.2KW | 35cm 108 valve | 28 | 82-84 |

| GH50-B | 1000*670*1000 | 450*830 | 90 | 220V 4 pôles 3KW | 35cm 108 valve | 28 | 82-84 |

| GH100-B | 1200*815*1200 | 570*1000 | 180 | 380V 4 pôles 3KW | 35cm 108 valve | 28 | 40-41 |

| GH200-B | 1360*1000*1400 | 780*1200 | 400 | 380V 4 pôles 3KW | 35cm 133 valve | 20 | 40-41 |

| GH300-B | 1700*1400*1900 | 900*1400 | 490 | 380V 4 pôles 3KW | 50cm 159 valve | 20 | 40-41 |

U-trough coffee mixer paramètres de la machine

| Modèle | Dimensions externes (mm) | Capacité (L) |

| TZ-60 | 570*600*1000 | 100 |

| TZ-100 | 700*830*1100 | 100 |

Avantages de la machine à mélanger le café

- Dual-mode flexibility. U-Type for coarse/low-fluidity powders (e.g., laundry detergent), Drum-Type for fine powders (e.g., coffee, spices).

- Precision mixing. Adjustable speed (0-1500 rpm) ensures uniform blending across densities.

- Durable & hygienic. 304 stainless steel (contact parts) + 201 steel frame, corrosion-resistant and food-safe.

- Scalable capacity. 60L-490L models (customizable up to 1000kg batches).

- Globally certified. Complies with FDA, TGA, and international standards.

- Stable operation. Low-speed drum rotation (20-28 rpm) minimizes heat; high-torque motors (2.2-4KW) ensure reliability.

- Easy logistics. Modular Drum-Type design for quick assembly/export; standardized discharge ports (35-50cm).

Équipements de soutien de la machine à mélanger les poudres

La machine à mélanger en poudre peut être utilisée en conjonction avec un concasseur grossier pour obtenir des résultats de mélange optimaux. Voici quelques points clés à considérer :

- Coarse crushing before blending. For materials like chili peppers, it is common to use a coarse crusher to initially break down the material to a size of 10-15 mesh. This coarse crushing step ensures that the material is suitable for further fine grinding.

- Fine grinding with toothed disk mill. After coarse crushing, the material can be further processed using a toothed disk mill to achieve a finer powder. This step is essential for achieving the desired consistency for products such as spices, coffee powder, and other fine powders.

- Capacity of coarse crusher. The coarse crusher can handle up to 60 mesh, with a processing capacity of around 300-400 kg per hour. This makes it an efficient choice for preparing materials for the Powder Blender Machine.

- Limitations with root and tuber crops. It is important to note that root and tuber crops should not be directly processed using a toothed disk mill for fine grinding, as this can lead to clogging of the screen. Instead, these materials should first be processed using a suitable coarse crusher to achieve the appropriate particle size before further grinding.

En intégrant un concasseur grossier avec la machine à mélanger en poudre, vous pouvez garantir un traitement efficace et efficace d'une large gamme de matériaux, du concassage grossier au broyage fin, tout en maintenant des performances optimales et en évitant des problèmes potentiels tels que le colmatage de l'écran.

Conclusion

La machine à mélanger en poudre garantit un mélange efficace et uniforme pour divers matériaux en poudre, en faisant un outil essentiel pour des industries telles que la transformation alimentaire, les produits pharmaceutiques et les produits chimiques. Avec sa vitesse réglable, ses multiples options de capacité et sa construction en acier inoxydable durable, elle offre une solution fiable pour obtenir des mélanges de haute qualité.

Pour rationaliser davantage la production, nos machines d'emballage en poudre peuvent être intégrées dans le processus, permettant un emballage précis et efficace du produit final. Cette solution tout-en-un garantit une transition fluide du mélange à l'emballage, améliorant la productivité et la commodité. Contactez-nous aujourd'hui pour personnaliser votre configuration de mélange et d'emballage en poudre !