ডিম ধোয়ার মেশিন | ডিম পরিষ্কার করার মেশিন

| মডেল | TZ-100 |

| ক্ষমতা | ১০,০০০-১৪,০০০পিস/ঘণ্টা |

| শক্তি | 1.5kw |

| ভোল্টেজ | 380ভি |

| আকার | 2600*1630*1100mm |

আপনি এখন আমাদের প্রকল্প ব্যবস্থাপকদের কাছ থেকে প্রযুক্তিগত বিস্তারিত জানতে পারেন

ডিম ধোয়ার মেশিন একটি উচ্চ-কার্যকরী সমাধান যা দক্ষতার সাথে এবং বহুমুখীভাবে পরিষ্কার করতে পারে, মডেলের উপর নির্ভর করে প্রতি ঘণ্টায় ১০,০০০ থেকে ১৪,০০০ ডিম প্রক্রিয়া করার ক্ষমতা রয়েছে।

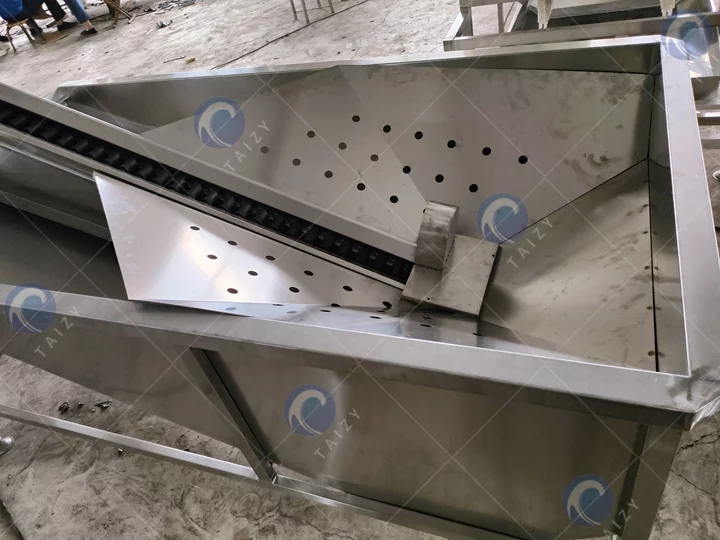

টেকসই স্টেইনলেস স্টিল দিয়ে নির্মিত, এটি বিভিন্ন ডিম, যেমন মুরগির, হাঁসের, হাঁসের এবং কোয়েল ডিমের স্বাস্থ্যকর পরিষ্কার নিশ্চিত করে, তাদের দাগহীন এবং চকচকে রেখে।

একক-রো, তিন-রো এবং ছয়-রো মডেলের মতো একাধিক কনফিগারেশনে উপলব্ধ, এই মেশিনটি বিভিন্ন গ্রাহকের চাহিদা পূরণ করে এবং সম্পূর্ণ পরিষ্কার, উচ্চ গতির এবং ক্ষতি প্রতিরোধের মতো বৈশিষ্ট্যগুলি অফার করে।

ডিম ধোয়ার মেশিন বিক্রয়ের জন্য

- ৩০৪ স্টেইনলেস স্টিল নির্মাণ। টেকসই এবং জারা-প্রতিরোধী শরীর এবং চেইন বিয়ারিং দীর্ঘমেয়াদী নির্ভরযোগ্যতা নিশ্চিত করে।

- উচ্চ-শক্তির নাইলন হেয়ার রোলার ব্রাশ। কার্যকর এবং দীর্ঘস্থায়ী ডিম পরিষ্কারের কর্মক্ষমতার জন্য ডিজাইন করা হয়েছে।

- পম ডিম-খাওয়ানো রাবার চাকা। মসৃণ অপারেশন এবং দীর্ঘস্থায়ীতা নিশ্চিত করার জন্য ডিজাইন করা হয়েছে, ডিম প্রক্রিয়াকরণের জন্য ধারাবাহিক ব্যবহারের জন্য আদর্শ।

বিভিন্ন প্রক্রিয়াকরণ স্কেলের জন্য, মেশিনটি বিভিন্ন মডেলে উপলব্ধ, যার মধ্যে রয়েছে:

- একক সারি. ছোট অপারেশনের জন্য আদর্শ।

- তিন সারি. মাঝারি স্কেলের প্রক্রিয়াকরণের জন্য উপযুক্ত।

- ছয় সারি. বড় স্কেলের ডিম প্রক্রিয়াকরণের প্রয়োজনের জন্য ডিজাইন করা।

ডিম ধোয়ার মেশিন কেনার প্রয়োজন কেন?

- ময়লা, দূষক এবং ব্যাকটেরিয়া অপসারণ করে। খাদ্য নিরাপত্তা এবং স্বাস্থ্যবিধি বাড়ায়।

- স্বয়ংক্রিয়ভাবে ডিম পরিষ্কার করে। সহজ জল ট্যাঙ্ক অপারেশনের মাধ্যমে সময় এবং শ্রম সাশ্রয় করে।

- খাদ্য-গ্রেড নরম উপকরণ দিয়ে তৈরি। পরিষ্কারের প্রক্রিয়ায় ডিম ভাঙার পরিমাণ কমায়।

- একক পরিষ্কার এবং শুকানোর ব্যবস্থা প্রদান করে। বাজারের উপস্থাপনার জন্য ধারাবাহিক চেহারা এবং গুণমান নিশ্চিত করে।

- বাজারের মূল্য বাড়ায়। পরিষ্কার এবং ভাল উপস্থাপিত ডিমগুলি ভাল দামের দাবি করতে পারে।

- একীভূত сортিং সিস্টেম। ত্রুটিপূর্ণ ডিম সনাক্ত করে এবং অপসারণ করে, সামগ্রিক পণ্যের গুণমান উন্নত করে।

ডিম ধোয়ার মেশিনটি কীভাবে কাজ করে?

লোডিং

ম্যানুয়ালি পুরো ঝুড়ি বা বাক্সের মুরগি বা হাঁসের ডিম জল ট্যাঙ্কে রাখুন।

পরিবহন

ডিমগুলি কনভেয়র রোলারগুলিতে পরিবহন করা হয়, যা সেগুলিকে সিস্টেম্যাটিকভাবে ব্রাশিং এলাকায় নিয়ে যায়।

ব্রাশিং

ডিমগুলি হেয়ার রোলারগুলির মধ্য দিয়ে যায়, যেখানে সেগুলি ঘূর্ণমান ব্রাশ দ্বারা সম্পূর্ণরূপে পরিষ্কার হয়।

ডিসচার্জ

পরিষ্কার ডিমগুলি পরে মেশিনের ডিসচার্জ প্রান্তে পরিবহন করা হয়।

পরীক্ষা

ত্রুটিপূর্ণ ডিমগুলি লাইন থেকে অপসারণ করা হয়।

শ্রেণীবিভাগ

যোগ্য ডিমগুলি একটি কনভেয়র বেল্টে স্থানান্তরিত হয়।

অতিরিক্ত প্রক্রিয়াকরণ

প্রয়োজনীয়তার উপর নির্ভর করে, ডিমগুলি বা তোলে একটি প্যাকেজিং মেশিনে পরিবহন করা হয় অথবা অতিরিক্ত প্রক্রিয়াকরণের জন্য একটি স্বয়ংক্রিয় ডিমের কুসুম এবং সাদা আলাদা করার যন্ত্রে নির্দেশিত হয়।

ডিম পরিষ্কারের মেশিনের প্রধান উপাদানসমূহ

- জল ট্যাঙ্ক. ৩৪০ স্টেইনলেস স্টিল দিয়ে তৈরি, জারা প্রতিরোধী, সহজ পরিষ্কার এবং টেকসই।

- ডিম পরিবহন র্যাক. ৩৪০ স্টেইনলেস স্টিল থেকে নির্মিত, টেকসই এবং জারা প্রতিরোধী নিশ্চিত করে।

- ডিম লোডিং রোলার. নরম, ক্ষয়-প্রতিরোধী উপকরণ ডিমের ক্ষতি প্রতিরোধ করে এবং সমান লোডিং নিশ্চিত করে।

- ডিম লোডিং চেইন. মোটা 304 স্টেইনলেস স্টিলের লিঙ্কগুলি স্থায়িত্ব প্রদান করে এবং বিকৃতি প্রতিরোধ করে।

- পরিষ্কারের ব্রাশ. পরিধান-প্রতিরোধী মোড়ানো তারের ব্রাশগুলি পৃষ্ঠের দাগগুলি কার্যকরভাবে অপসারণ করে, যখন স্টেইনলেস স্টিলের ব্রাশ অক্ষ ক্ষয় প্রতিরোধ করে।

- ফ্রেম. স্টিল প্লেট বাঁকানো বা বর্গক্ষেত্র টিউব ডিজাইনে উপলব্ধ; মডিউল-অ্যাসেম্বলি সংস্করণগুলি ওয়েল্ড-মুক্ত এবং অত্যন্ত স্থায়ী।

- ভিজ্যুয়াল পরিদর্শন. LED ঠান্ডা আলো অ-ধ্বংসাত্মক পরীক্ষার এবং ত্রুটিপূর্ণ ডিমের ম্যানুয়াল অপসারণ সক্ষম করে।

- কনভেয়র বেল্ট. নিরাপদ, কার্যকর ডিম পরিবহনের জন্য খাদ্য-গ্রেড PVC থেকে তৈরি।

ডিম পরিষ্কারের মেশিনটি ভেরিয়েবল ফ্রিকোয়েন্সি স্পিড কন্ট্রোলের সাথে অত্যন্ত কার্যকর, মেশিনের স্পেসিফিকেশনের উপর নির্ভর করে প্রতি ঘণ্টায় অনেক ডিম ধোয়ার সক্ষম। প্রক্রিয়াকৃত ডিমগুলি পরিষ্কার, চকচকে এবং অন্যান্য যন্ত্রপাতির সাথে সহজেই একত্রিত করা যায়।

ডিম ধোয়ার মেশিনের প্যারামিটারসমূহ

| মডেল | TZ-100 |

| ক্ষমতা | ১০,০০০-১৪,০০০পিস/ঘণ্টা |

| ভোল্টেজ | 380ভি |

| শক্তি | 1.5kw |

| আকার | 2600*1630*1100mm |

ডিম ধোয়ার মেশিনের সহায়ক যন্ত্রপাতি

আমাদের ডিম ধোয়ার মেশিনকে ডিম প্রক্রিয়াকরণের কাজের প্রবাহকে আরও অপ্টিমাইজ করতে কয়েকটি সহায়ক যন্ত্রপাতির সাথে উন্নত করা যেতে পারে।

- UV জীবাণুনাশকএই ডিভাইসটি আলট্রাভায়োলেট লাইট ব্যবহার করে ডিমের পৃষ্ঠের ব্যাকটেরিয়া কার্যকরভাবে নির্মূল করে, উচ্চতর স্বাস্থ্য ও নিরাপত্তা মান নিশ্চিত করে।

- ডিম শ্রেণীবিভাগের মেশিনএই মেশিনটি ডিমগুলোকে তাদের ওজন অনুযায়ী শ্রেণীবদ্ধ করে, শ্রেণীবদ্ধকরণ প্রক্রিয়াকে সহজতর করে এবং প্যাকেজিংয়ের জন্য ধারাবাহিক গুণমান এবং আকার নিশ্চিত করে।

- ডিম মুদ্রণ মেশিনএটি গুরুত্বপূর্ণ তথ্য, যেমন তারিখ এবং প্রস্তুতকারকের বিবরণ, সরাসরি ডিমের পৃষ্ঠে মুদ্রণ করে। এটি গুণমান নিয়ন্ত্রণ এবং সম্মতির জন্য গুরুত্বপূর্ণ ট্রেসেবিলিটি এবং লেবেলিং প্রদান করে।

এই সংযোজনগুলি ডিম ধোয়ার মেশিনকে সম্পূরক করে, কার্যকরভাবে ডিম পরিষ্কার, শ্রেণীবদ্ধ এবং লেবেল করার জন্য একটি সমন্বিত সমাধান প্রদান করে।

আমাদের সাথে যোগাযোগ করুন!

আমাদের ডিম ধোয়ার মেশিন নির্বাচন করে, আপনি কেবল উন্নত এবং নির্ভরযোগ্য সরঞ্জামে বিনিয়োগ করছেন না বরং Taizy-এর সাথে অংশীদারিত্ব করছেন, যা খাদ্য প্রক্রিয়াকরণ শিল্পে গুণমানের প্রতি প্রতিশ্রুতির জন্য পরিচিত।

আমাদের মেশিনগুলি সঠিকতা নিয়ে ডিজাইন করা হয়েছে এবং দীর্ঘস্থায়ী নির্মাণের জন্য তৈরি, আপনার কার্যক্রমে সর্বোত্তম কর্মক্ষমতা নিশ্চিত করে। বছরের পর বছর অভিজ্ঞতা এবং গ্রাহক সন্তুষ্টির শক্তিশালী ট্র্যাক রেকর্ড নিয়ে, আমরা আপনার ব্যবসার প্রয়োজনীয়তাগুলি সমর্থন করতে প্রস্তুত।

আজই আমাদের সাথে যোগাযোগ করুন যাতে আপনি জানতে পারেন কিভাবে আমাদের ডিম ধোয়ার মেশিন আপনার উৎপাদন লাইনের উন্নতি করতে পারে এবং আপনার প্রয়োজনীয়তার জন্য একটি ব্যক্তিগতকৃত উদ্ধৃতি পেতে পারেন।