ম্যাকাডামিয়া বাদাম প্রক্রিয়াকরণ লাইন

| ক্ষমতা | 1000kg/h |

| আকার | ৫৫০০*১১০০*২১৭০মিমি |

| শক্তি | ২.২কিলোওয়াট |

| ভোল্টেজ | ৩৮০ভি, ৫০হিজ |

| ওজন | ২৩৫০কেজি |

আপনি এখন আমাদের প্রকল্প ব্যবস্থাপকদের কাছ থেকে প্রযুক্তিগত বিস্তারিত জানতে পারেন

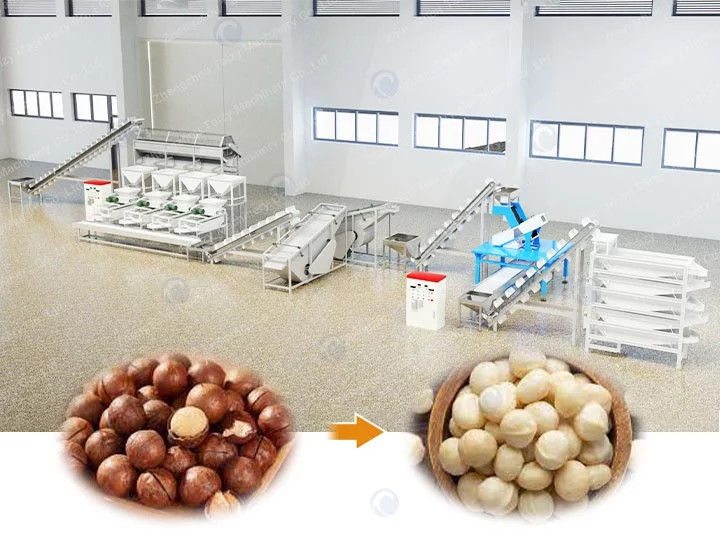

ম্যাকাডামিয়া বাদামের প্রক্রিয়াকরণ লাইনটি ম্যাকাডামিয়া বাদাম প্রক্রিয়াকরণের জন্য ব্যবহৃত হয়, যার মধ্যে গ্রেডিং, শেলিং এবং রঙ নির্বাচন অন্তর্ভুক্ত রয়েছে। এই উৎপাদন লাইনটি শেল বাদাম, কের্নেল বাদাম ইত্যাদির মতো বিভিন্ন বাদাম প্রক্রিয়াকরণের জন্য উপযুক্ত।

আমাদের অত্যাধুনিক ম্যাকাডামিয়া বাদামের প্রক্রিয়াকরণ লাইনটি ম্যাকাডামিয়া বাদামের উৎপাদনের দক্ষতা এবং গুণমান বাড়ানোর জন্য ডিজাইন করা হয়েছে। এই উদ্ভাবনী প্রক্রিয়াকরণ লাইনটি উৎপাদন প্রক্রিয়ার প্রতিটি পদক্ষেপকে সহজতর করার জন্য যত্ন সহকারে তৈরি করা হয়েছে, সর্বোচ্চ মানের বাদামের গুণমান নিশ্চিত করে এবং সম্পদ ব্যবহারের অপ্টিমাইজেশন করে।

নির্ভুলতার সাথে তৈরি এবং গুণমানের প্রতি প্রতিশ্রুতিবদ্ধ, এই একীভূত সিস্টেমটি ম্যাকাডামিয়া বাদামের উৎপাদনের মানদণ্ডকে নতুন করে সংজ্ঞায়িত করে, শিল্পের জন্য একটি নতুন মানদণ্ড স্থাপন করে।

ম্যাকাডামিয়া বাদাম উৎপাদন লাইনের প্রধান যন্ত্র

1. হোস্ট

হোস্ট হল ম্যাকাডামিয়া বাদামের প্রক্রিয়াকরণ লাইনের একটি মৌলিক উপাদান। এটি কাঁচা ম্যাকাডামিয়া বাদামগুলোকে প্রক্রিয়াকরণ লাইনের শুরুতে তোলার এবং পরিবহনের জন্য দায়ী। এখানে কিছু মূল বৈশিষ্ট্য রয়েছে:

- কার্যকর উপাদান পরিচালনা: হোস্টটি কাঁচা ম্যাকাডামিয়া বাদামগুলোকে প্রাথমিক স্টোরেজ এলাকা থেকে প্রক্রিয়াকরণ লাইনে মসৃণভাবে স্থানান্তরিত করে, কাজের প্রবাহকে অপ্টিমাইজ করে।

- সামঞ্জস্যযোগ্য লিফটিং ক্ষমতা: অপারেটররা বিভিন্ন ব্যাচ আকারের জন্য হোস্টের লিফটিং ক্ষমতা সামঞ্জস্য করতে পারেন, উৎপাদনে নমনীয়তা প্রদান করে।

- নিরাপত্তা বৈশিষ্ট্য: হোস্টটি দুর্ঘটনা প্রতিরোধ এবং অপারেটরদের সুস্থতা নিশ্চিত করার জন্য নিরাপত্তা যন্ত্রপাতি দিয়ে সজ্জিত।

2. গ্রেডিং মেশিন

গ্রেডিং মেশিন হল ম্যাকাডামিয়া বাদামের প্রক্রিয়াকরণ লাইনের একটি গুরুত্বপূর্ণ উপাদান। এটি ম্যাকাডামিয়া বাদামগুলোকে আকার অনুযায়ী শ্রেণীবদ্ধ করার জন্য ডিজাইন করা হয়েছে, চূড়ান্ত পণ্যে একরূপতা নিশ্চিত করে। এখানে কিছু মূল বৈশিষ্ট্য রয়েছে:

- আকারের শ্রেণীবিভাগ: মেশিনটি কার্যকরভাবে ম্যাকাডামিয়া বাদামগুলোকে বিভিন্ন আকারের শ্রেণীতে আলাদা করে, সঠিক গ্রেডিংয়ের জন্য অনুমতি দেয়।

- সামঞ্জস্যযোগ্য প্যারামিটার: অপারেটররা সহজেই নির্দিষ্ট গ্রেডিং প্রয়োজনীয়তার জন্য সেটিংস সামঞ্জস্য করতে পারেন, বিভিন্ন বাদামের আকার প্রক্রিয়াকরণের জন্য নমনীয়তা প্রদান করে।

- উচ্চ থ্রুপুট: গ্রেডিং মেশিনটি একটি বড় পরিমাণ বাদাম পরিচালনা করতে সক্ষম, প্রক্রিয়াকরণ লাইনের সামগ্রিক কার্যকারিতায় অবদান রাখে।

- সঠিকতা এবং একরূপতা: উন্নত সেন্সর প্রযুক্তি ব্যবহার করে, গ্রেডিং মেশিনটি সঠিক শ্রেণীবিভাগ নিশ্চিত করে, গ্রেডেড বাদামের মানের একরূপতা ফলস্বরূপ।

3. শেলিং মেশিন

শেলিং মেশিনটি ম্যাকাডামিয়া বাদামগুলোকে ভাঙার জন্য দায়ী, যা ভিতরে মূল্যবান বাদামের কোরগুলিতে প্রবেশের অনুমতি দেয়। এখানে কিছু মূল বৈশিষ্ট্য রয়েছে:

- কার্যকর শেল ভাঙা: এই মেশিনটি ম্যাকাডামিয়া বাদামের শেলের ভাঙা প্রক্রিয়ায় কোরগুলিকে ক্ষতিগ্রস্ত না করার জন্য সঠিক যন্ত্রপাতি ব্যবহার করে।

- সামঞ্জস্যযোগ্য ভাঙার তীব্রতা: অপারেটররা বিভিন্ন বাদামের প্রজাতি এবং শেলের পুরুত্বের জন্য ভাঙার তীব্রতা সূক্ষ্মভাবে সামঞ্জস্য করার ক্ষমতা রাখেন।

- সতর্ক হ্যান্ডলিং: শেলিং প্রক্রিয়াটি কোরের ভাঙন কমানোর জন্য ডিজাইন করা হয়েছে, অক্ষত বাদামের কোরের উচ্চ ফলন নিশ্চিত করে।

- নিরাপত্তা বৈশিষ্ট্য: শেলিং মেশিনটি অপারেটরদের সুরক্ষার জন্য এবং যন্ত্রপাতির ক্ষতি প্রতিরোধের জন্য নিরাপত্তা যন্ত্রপাতি অন্তর্ভুক্ত করে।

4. পরিবহন বেল্ট

পরিবহন বেল্টগুলি প্রক্রিয়াকরণ লাইনের একটি অবিচ্ছেদ্য অংশ, ম্যাকাডামিয়া বাদামগুলোকে এক প্রক্রিয়াকরণ পর্যায় থেকে অন্য পর্যায়ে স্থানান্তরিত করতে সহায়তা করে। এখানে কিছু মূল বৈশিষ্ট্য রয়েছে:

- মসৃণ উপাদান পরিবহন: পরিবহন বেল্টগুলি বিভিন্ন প্রক্রিয়াকরণ উপাদানের মধ্যে ম্যাকাডামিয়া বাদামগুলোর মৃদু এবং কার্যকর স্থানান্তর নিশ্চিত করার জন্য ডিজাইন করা হয়েছে।

- সামঞ্জস্যযোগ্য গতি: অপারেটররা প্রক্রিয়াকরণ লাইনের গতির সাথে সমন্বয় করতে পরিবহন বেল্টগুলোর গতি নিয়ন্ত্রণ করতে পারেন, সামগ্রিক কার্যকারিতা অপ্টিমাইজ করে।

- টেকসই এবং কম রক্ষণাবেক্ষণ: উচ্চমানের উপকরণ দিয়ে নির্মিত, পরিবহন বেল্টগুলি টেকসই এবং ন্যূনতম রক্ষণাবেক্ষণের জন্য নির্মিত।

5. সেপারেটর মেশিন

সেপারেটর মেশিনটি ভাঙা বাদামের শেলের টুকরোগুলোকে মূল্যবান বাদামের কোর থেকে আলাদা করার জন্য দায়ী। এখানে কিছু মূল বৈশিষ্ট্য রয়েছে:

- কার্যকর শেল অপসারণ: এই মেশিনটি বাতাসের প্রবাহ এবং যান্ত্রিক বিচ্ছেদকে একত্রিত করে কার্যকরভাবে ভাঙা শেলের টুকরোগুলোকে কোর থেকে অপসারণ করে।

- সামঞ্জস্যযোগ্য বাতাসের প্রবাহ সেটিংস: অপারেটররা বিভিন্ন বাদামের প্রজাতি এবং শেলের অবস্থার জন্য বিচ্ছেদ প্রক্রিয়াকে অপ্টিমাইজ করতে বাতাসের প্রবাহের প্যারামিটারগুলি সামঞ্জস্য করতে পারেন।

- উচ্চ ফলন: সেপারেটর মেশিনটি অক্ষত বাদামের কোরের পুনরুদ্ধার সর্বাধিক করতে ডিজাইন করা হয়েছে, বর্জ্য কমিয়ে এবং উৎপাদনের আউটপুট অপ্টিমাইজ করে।

- সহজ রক্ষণাবেক্ষণ: মেশিনের ডিজাইন সহজ পরিষ্কার এবং রক্ষণাবেক্ষণের জন্য সুবিধাজনক, মসৃণ এবং বিঘ্নহীন অপারেশন নিশ্চিত করে।

6. রঙ শ্রেণীবিভাজক

রঙ শ্রেণীবিভাজক হল একটি উন্নত প্রযুক্তি যা ম্যাকাডামিয়া বাদামের গুণমানকে আরও পরিশীলিত করে ত্রুটিপূর্ণ বা রঙহীন বাদামগুলোকে চিহ্নিত এবং অপসারণ করে। এখানে কিছু মূল বৈশিষ্ট্য রয়েছে:

- উচ্চ-গতির শ্রেণীবিভাগ: রঙ শ্রেণীবিভাজক উচ্চ-গতির ক্যামেরা এবং উন্নত অ্যালগরিদম ব্যবহার করে দ্রুত রঙের অমিলের ভিত্তিতে বাদামগুলোকে চিহ্নিত এবং আলাদা করে।

- কাস্টমাইজড শ্রেণীবিভাগ মানদণ্ড: অপারেটররা অস্বাভাবিকতা যেমন রঙহীনতা, ছাঁচ বা অন্যান্য ত্রুটির লক্ষ্য করার জন্য নির্দিষ্ট শ্রেণীবিভাগ মানদণ্ড সেট করতে পারেন।

- বর্ধিত গুণমান নিয়ন্ত্রণ: নিচের মানের বাদামগুলো অপসারণ করে, রঙ শ্রেণীবিভাজক নিশ্চিত করে যে শুধুমাত্র উচ্চমানের বাদামগুলো চূড়ান্ত প্যাকেজিং পর্যায়ে অগ্রসর হয়।

- উন্নত নান্দনিক আবেদন: রঙ শ্রেণীবিভাজক চূড়ান্ত পণ্যের সামগ্রিক চেহারা উন্নত করে, বাজারে উচ্চ নান্দনিক মান পূরণ করে।

এই উপাদানগুলো আপনার ম্যাকাডামিয়া বাদামের প্রক্রিয়াকরণ লাইনে একসাথে নিখুঁতভাবে কাজ করে, কাঁচা বাদাম থেকে উচ্চমানের, বাজারে প্রস্তুত পণ্যগুলিতে একটি সুশৃঙ্খল এবং কার্যকর প্রক্রিয়া নিশ্চিত করে। প্রতিটি মেশিন সঠিকতা এবং উন্নত প্রযুক্তির সাথে ডিজাইন করা হয়েছে যাতে প্রিমিয়াম ম্যাকাডামিয়া বাদামের ফলন সর্বাধিক হয়।

ম্যাকাডামিয়া বাদামের প্রক্রিয়াকরণ লাইনের কাজের প্রক্রিয়া

১. কাঁচা ম্যাকাডামিয়া বাদামগুলি শ্রেণীবিভাগ মেশিনে প্রবেশ করে একটি হোস্ট দ্বারা শ্রেণীবদ্ধ করা হয় এবং তিন বা তার বেশি স্তরে আলাদা করা হয়। তিন বা চারটি শেলের জন্য শেলের মধ্যে প্রবেশ করতে বৈদ্যুতিন পরিমাণ ফিড হপার রয়েছে।

২. শেলিং মেশিন (শেলিং মেশিনের শেলিং গ্যাপ কাঁচামালের আকার অনুযায়ী সমন্বয় এবং মেলানো হয়, যাতে শেল করা এবং পরিষ্কার কোর সম্পূর্ণ হয়)। শেলের এবং কোরগুলি সংগ্রহকারী বেল্ট দ্বারা পরিবাহিত হয় এবং শেলের এবং কোর আলাদা করার জন্য দুটি শেল এবং কোর আলাদা করার যন্ত্রে প্রবেশ করে।

৩. শেল এবং কোর আলাদা করার যন্ত্র শেল এবং কোর আলাদা করে, এবং কোর একটি উপাদান পোর্ট থেকে বের হয়, এবং শেল অন্য উপাদান পোর্ট থেকে বের হয়। আউটপুট আকার এবং কাঁচামালের আকার অনুযায়ী, এটি ডিজাইন এবং কাস্টমাইজ করা যেতে পারে।

মূল বৈশিষ্ট্য এবং সুবিধাসমূহ ম্যাকাডামিয়া বাদামের প্রক্রিয়াকরণ লাইন

- সর্বাধিক কার্যকরী কাজের প্রবাহ: আমাদের প্রক্রিয়াকরণ লাইন বাদাম ভাঙা এবং খোসা ছাড়ানো থেকে শুরু করে сортিং পর্যন্ত নির্বিঘ্নে একত্রিত হয়, একটি ধারাবাহিক এবং কার্যকরী অপারেশন প্রদান করে যা আউটপুট সর্বাধিক করে।

- সর্বাধুনিক প্রযুক্তি: বাদাম প্রক্রিয়াকরণ প্রযুক্তির সর্বশেষ অগ্রগতিগুলি ব্যবহার করে, আমাদের লাইন ভাঙা এবং сортিংয়ের মতো কাজের জন্য সঠিক যন্ত্রপাতি ব্যবহার করে, যা ধারাবাহিক গুণমান নিশ্চিত করে এবং অপচয় কমায়।

- কাস্টমাইজেশন বিকল্প: নির্দিষ্ট উৎপাদন প্রয়োজনীয়তা পূরণের জন্য কাস্টমাইজ করা হয়েছে, আমাদের প্রক্রিয়াকরণ লাইন বিভিন্ন বাদামের আকার এবং প্রক্রিয়াকরণের ক্ষমতা পরিচালনা করার জন্য কনফিগার করা যেতে পারে, বিভিন্ন অপারেশনাল প্রয়োজনীয়তার জন্য একটি বহুমুখী সমাধান প্রদান করে।

- কঠোর গুণমান নিয়ন্ত্রণ: আমাদের লাইন প্রক্রিয়াকরণের প্রতিটি পর্যায়ে কঠোর গুণমান নিয়ন্ত্রণ ব্যবস্থা অন্তর্ভুক্ত করে, নিশ্চিত করে যে শুধুমাত্র সর্বোচ্চ মানের ম্যাকাডামিয়া বাদাম চূড়ান্ত প্যাকেজিংয়ে পৌঁছায়, সবচেয়ে কঠোর শিল্প মান পূরণ করে।

- কার্যকর বাদাম শেলের অপসারণ: লাইনটি কার্যকর বাদাম শেলের অপসারণের জন্য বিশেষায়িত যন্ত্রপাতি দিয়ে সজ্জিত, বাদামের কোরের ক্ষতি কমিয়ে এবং প্রিমিয়াম-গ্রেড বাদামের ফলন সর্বাধিক করে।

- ব্যবহারকারী-বান্ধব ইন্টারফেস: স্বচ্ছ নিয়ন্ত্রণ ব্যবস্থা সহজ অপারেশন এবং সমন্বয়ের অনুমতি দেয়, অপারেটরদের প্রক্রিয়াকরণের প্যারামিটারগুলি পর্যবেক্ষণ এবং সূক্ষ্ম-সামঞ্জস্য করতে সক্ষম করে।

- মজবুত নির্মাণ: উচ্চমানের উপকরণ এবং উপাদান দিয়ে নির্মিত, আমাদের প্রক্রিয়াকরণ লাইন টেকসইতা এবং দীর্ঘস্থায়ী জন্য ডিজাইন করা হয়েছে, নিশ্চিত করে যে বছরের পর বছর নির্ভরযোগ্য অপারেশন হয় এবং কম রক্ষণাবেক্ষণের প্রয়োজন হয়।

- ব্যাপক বিক্রয়োত্তর সহায়তা: আমাদের নিবেদিত বিশেষজ্ঞদের দল ব্যাপক বিক্রয়োত্তর সহায়তা প্রদান করে, রক্ষণাবেক্ষণ, সমস্যা সমাধান এবং প্রশিক্ষণ সহ, যাতে অবিচ্ছিন্ন অপারেশন নিশ্চিত হয় এবং প্রক্রিয়াকরণ লাইনের আয়ু সর্বাধিক হয়।

ম্যাকাডামিয়া বাদামের প্রক্রিয়াকরণ লাইনের প্যারামিটারসমূহ

| নাম | প্যারামিটারসমূহ |

| হোস্ট | আকার: 5000*600*600মিমি শক্তি: 2.2কিলোওয়াট |

| শেলিংয়ের আগে গ্রেডিং মেশিন | আকার: 5500*1100*2170মিমি ক্ষমতা: 1000কেজি/ঘণ্টা ওজন: 2300কেজি শক্তি: 2.2কিলোওয়াট ভোল্টেজ: 380ভি, 50হিজ |

| বৈদ্যুতিন পরিমাণ ফিডিং হপার | আকার: 1000*1000*1600মিমি শক্তি: 0.05কিলোওয়াট ভোল্টেজ: 380ভি, 50হিজ |

| শেলিং মেশিন | ক্ষমতা: 300-400কেজি/ঘণ্টা শক্তি: 3কিলোওয়াট ভোল্টেজ: 380ভি, 50হিজ আকার: 1600*1000*1550মিমি ওজন: 280কেজি |

| পরিবহন বেল্ট | আকার: 6000*600*1500মিমি শক্তি: 0.75কিলোওয়াট ভোল্টেজ: 380ভি, 50হিজ |

| ফিডার এবং এলিভেটর | শক্তি: 0.75কিলোওয়াট ভোল্টেজ 380ভি, 50হিজ আকার: 3700*500*500মিমি ওজন: 160কেজি |

| আলাদা করার যন্ত্র | আকার: 2500*1100*1600মিমি ওজন: 350কেজি শক্তি: ৩কিলোওয়াট ভোল্টেজ: 380ভি, 50হিজ ক্ষমতা: 600–1000কেজি/ঘণ্টা |

| হোস্ট | আকার: 3500*650*650মিমি শক্তি: 0.75কিলোওয়াট ভোল্টেজ: 380ভি, 50হিজ |

| পরিবহন বেল্ট | আকার: 5000*600*1500মিমি শক্তি: 0.75কিলোওয়াট ভোল্টেজ: 380ভি, 50হিজ |

| রঙ বাছাইকারী | ক্ষমতা: 1.5-2.0টন/ঘণ্টা বাছাইয়ের সঠিকতা(%):≥99% বহন অনুপাত: ≥20:1 রেজোলিউশন: 0.025মিমি² শক্তি: 3কিলোওয়াট ভোল্টেজ: 380ভি, 50হিজ আকার: 1872*1520*2090মিমি বায়ু খরচ: 1.5-2.0ম³/মিনিট বায়ু চাপ: 0.5-0.8এমপিএ ওজন: 975কেজি |

| শেলিংয়ের পরে গ্রেডিং মেশিন | ক্ষমতা: 1000-1500কেজি/ঘণ্টা আকার: 2400*800*2200মিমি ওজন: 500কেজি শক্তি: 1.5কিলোওয়াট ভোল্টেজ: 380ভি, 50হিজ |

পরবর্তী বিক্রয় সেবা

আমাদের কোম্পানিতে কেনা সমস্ত পণ্য এক বছরের জন্য ভাল মেরামত রাখতে গ্যারান্টি দেওয়া হয়। মেশিনের নিজস্ব এবং গুণমানের কারণে যে ত্রুটি ঘটে তা আমাদের প্রস্তুতকারকের দায়িত্ব। অপারেশন ভুল, মানবসৃষ্ট সমস্যা ইত্যাদির কারণে যে অন্যান্য ত্রুটি ঘটে তা ক্লায়েন্টের নিজস্ব দায়িত্ব।

ব্যবহারের সময় কোনও সমস্যা হলে, পেশাদার পরামর্শ দেওয়া হবে। অতিরিক্তভাবে, আমাদের কোম্পানি জীবনব্যাপী প্রযুক্তিগত সহায়তা এবং ফিটিং প্রদান করে। বিক্রয়োত্তর পরিষেবা সময় দ্বারা সীমাবদ্ধ নয় এবং আমরা সময়মতো আপনার সমস্যাগুলি সমাধান করব। যদি আপনি আমাদের পণ্য ব্যবহার করার সময় কিছু সমস্যায় পড়েন, যে কোনও সময় আমাদের সাথে যোগাযোগ করতে স্বাগতম।

আমাদের ম্যাকাডামিয়া বাদামের প্রক্রিয়াকরণ লাইন কেন নির্বাচন করবেন?

আমরা পরিবেশগত স্থায়িত্বকে অগ্রাধিকার দিই এবং আমাদের প্রক্রিয়াকরণ লাইনের ডিজাইনে পরিবেশ-বান্ধব অনুশীলনগুলি অন্তর্ভুক্ত করেছি। শক্তি-দক্ষ উপাদান থেকে বর্জ্য হ্রাসের ব্যবস্থা পর্যন্ত, আমাদের সিস্টেম টেকসই খাদ্য উৎপাদনের দিকে বৈশ্বিক প্রচেষ্টার সাথে সঙ্গতিপূর্ণ।

আমাদের ম্যাকাডামিয়া বাদামের প্রক্রিয়াকরণ লাইনে বিনিয়োগ করুন এবং ম্যাকাডামিয়া বাদাম উৎপাদনে দক্ষতা, গুণমান এবং নির্ভরযোগ্যতার একটি নতুন স্তর অনুভব করুন। আপনার বাদাম প্রক্রিয়াকরণ কার্যক্রমকে একটি সমাধান দিয়ে উন্নীত করুন যা শিল্প মান স্থাপন করে এবং আপনার গ্রাহকদের জন্য প্রিমিয়াম বাদাম পণ্য নিশ্চিত করে।

আজই আমাদের সাথে যোগাযোগ করুন যাতে আপনি জানতে পারেন কিভাবে আমাদের ম্যাকাডামিয়া বাদামের প্রক্রিয়াকরণ লাইন আপনার বাদাম প্রক্রিয়াকরণ ব্যবসাকে বিপ্লবী করতে পারে।