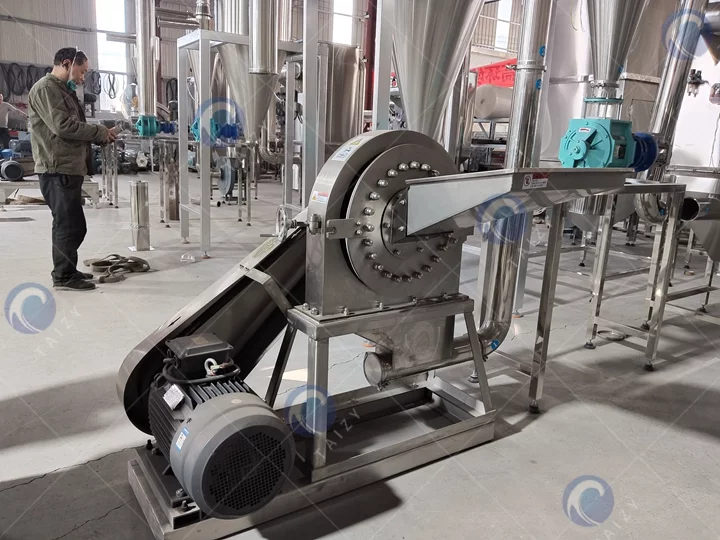

آلة سحق الحبوب

| اسم | آلة سحق الحبوب |

| مادة | 304 الفولاذ المقاوم للصدأ |

| النعومة | 10-120 شبكة |

| التطبيق | المواد الكيميائية، الحبوب، الأعشاب الطبية الصينية التقليدية، والتوابل |

يمكنك الآن أن تطلب من مديري المشاريع لدينا الحصول على التفاصيل الفنية

يمكن لآلة سحق الحبوب معالجة مجموعة واسعة من المواد الخام، بما في ذلك المواد الكيميائية، والحبوب، والأعشاب الطبية الصينية التقليدية، والتوابل (مثل النجمة اليانسون). مع نطاق نعومة قابل للتعديل من 10-120 شبكة، يمكن للمستخدمين تحقيق الحجم الجزيئي المطلوب ببساطة عن طريق استبدال المنخل.

تتوفر الآلة مع نوعين من القادوس: عمودي ومائل، لتلبية احتياجات التغذية المختلفة. مصنوعة من الفولاذ المقاوم للصدأ 304 لأجزاء الاتصال بالمواد و201 للفريم، تضمن هذه السحق المتانة، والنظافة، والامتثال لمعايير سلامة الغذاء والأدوية.

مطحنة مسحوق للبيع

تم تصميم آلة سحق الحبوب لدينا للتعامل مع مجموعة متنوعة من المواد الخام مع أداء طحن متسق. على عكس بعض المنافسين، تضمن غرفة الطحن لدينا معالجة موحدة لمواد مختلفة دون الحاجة إلى تعديلات.

المزايا الرئيسية لطاحونة الذرة والقمح

- التعامل مع المواد بشكل متعدد الاستخداماتتم تصميم المطحنة للتعامل مع أربعة أنواع رئيسية من المواد الخام، مما يضمن أداءً مثاليًا لكل منها. يمكن ضبط نعومة الطحن من 10 إلى 120 شبكة ببساطة عن طريق تغيير الشاشة، مما يجعلها مناسبة لمجموعة متنوعة من التطبيقات.

- خيارات تسليم مرنةتتميز الآلة بوجود قواديس رأسية ومائلة لتلبية احتياجات التغذية المختلفة، مما يعزز المرونة التشغيلية.

- جودة الموادمصنوع من الفولاذ المقاوم للصدأ 304 لأجزاء الاتصال المادية والفولاذ المقاوم للصدأ 201 للمكونات الأخرى، يضمن المطحنة المتانة ومقاومة التآكل.

- خيارات محرك قابلة للتخصيصبينما نقدم تكوينات المحركات القياسية، نقدم أيضًا خيارات محركات مخصصة لتلبية المتطلبات التشغيلية المحددة. عادةً ما تستغرق طلبات المحركات المخصصة سبعة أيام لإكمالها، مما يضمن التناسب المثالي مع احتياجاتك.

- تكامل سلسيمكن دمج المطحنة مع معدات أخرى، مثل آلة التعبئة, لإنشاء خط إنتاج سلس وفعال.

النماذج الشائعة

- آلة سحق الحبوب مع جامع غبار واحد

- آلة سحق الحبوب مع جامع غبار كيس دوامة

- آلة سحق الحبوب مع جامع غبار نبضي

مطحنة البودرة هي خيار ممتاز للشركات التي تتطلع إلى تعزيز قدراتها في المعالجة مع ضمان نتائج عالية الجودة.

سواء كنت بحاجة إلى معالجة مواد خشنة أو ناعمة، فإن مطحنةنا توفر المرونة والكفاءة المطلوبة لتحقيق الأداء الأمثل. اتصل بنا اليوم لمعرفة المزيد عن مطحنة البودرة وكيف يمكن أن تفيد عملك.

النموذج 1: آلة سحق الحبوب مع جامع غبار واحد

مطحنة الذرة مع جامع غبار فردي هي حل طحن عملي وفعال لمواد متنوعة. تتميز بكيس جمع الغبار المثبت في الأعلى، مما يلتقط الغبار الناعم بفعالية ويقلل من الجسيمات المحمولة في الهواء لبيئة عمل أنظف.

- Efficient dust collection. The upper dust bag ensures dust is collected directly, minimizing waste and improving air quality.

- Optimized discharge design. Processed materials are discharged smoothly from the bottom, ensuring continuous operation.

- Powerful airflow support. Equipped with a 1.5kW standard small fan, the system enhances material flow and dust removal efficiency.

- Durable stainless steel construction. Ensures hygiene, corrosion resistance, and long service life.

هذا الطراز مثالي للصناعات التي تتطلب التحكم المعتدل في الغبار، مثل معالجة التوابل والحبوب ومساحيق الكيميائيات.

Model 2: آلة سحق الحبوب مع جامع غبار كيس دوامة

مطحنة المسحوق مع جامع غبار كيس دوامة مصممة للتحكم الفعال في الغبار وفصل المواد، مما يجعلها مثالية للصناعات التي تتطلب عملية طحن نظيفة ودقيقة.

- High-efficiency cyclone dust removal. With a 90% dust collection efficiency, this system ensures that materials fall while gases are extracted, maintaining a dust-free working environment.

- Customizable cyclone sizes. Different materials require different cyclone diameters, with standard options of 380mm, 500mm, 600mm, and 750mm. Larger cyclones enhance dust separation, especially for fine powders.

- Airlock valve for heavy material separation. Equipped with 4.6L, 5L, 6L, or 7L airlock valves, which allow denser materials to drop while fine dust and air are extracted من خلال مروحة الضغط السلبي.

- مروحة ضغط سلبي قوية. يتم دعم النظام بواسطة مروحة ضغط سالب مع خيارات طاقة تبلغ 3 كيلو وات، 4 كيلو وات، 5.5 كيلو وات، 7.5 كيلو وات، و11 كيلو وات, مما يضمن تدفق هواء قوي لجمع الغبار بشكل فعال.

- نظام جمع غبار الأكياسيتم جمع الغبار الناعم بشكل منفصل في أكياس الغبار, مما يمنع فقدان المواد ويحافظ على نظافة مساحة العمل.

هذا الطراز مثالي لطحن المساحيق الناعمة في الصناعات مثل معالجة الطعام والأدوية والكيماويات، حيث تكون الدقة والتحكم في الغبار أمرين أساسيين.

موديل 3: آلة سحق الحبوب مع جامع غبار نبضي

آلة سحق الحبوب مع جامع غبار نبضي هي حل طحن عالي الأداء مصمم لمعالجة المساحيق فائقة النعومة مع تصفية غبار متفوقة. تتميز بنظام إزالة غبار نبضي متقدم، يضمن هذا الطراز بيئة عمل نظيفة وفعالة وصديقة للبيئة.

- 99% كفاءة عالية في تصفية الغبار. ال جامع الغبار النبضي يزيل 99% من الجسيمات المحمولة في الهواء., مما يجعله مثاليًا لـ طحن المسحوق الناعم في صناعات مثل المواد الكيميائية والأدوية ومعالجة الأغذية.

- صمامات نبضية متعددة لتحسين التنظيف. متوفر مع 12 أو 24 أو 30 أو 36 أو 48 صمام نبضي، مما يوفر قوة قوية لإزالة الغبار. يوصى بإعدادات أكبر للمواد الأثقل. وبودرة كيميائية دقيقة.

- أكياس فلتر مصنوعة من البوليستر المدقوق المتين. مصنوعة من قماش بوليستر عالي الجودة، أكياس الفلتر بكفاءة تلتقط جزيئات الغبار الدقيقة حتى 200 شبكة، مما يمنع التلوث الهوائي.

- نظام تنظيف بالهواء المضغوط عالي الضغط. يتم حقن الهواء المضغوط في جامع الغبار.، لضمان تنظيف الفلاتر بشكل شامل وتشغيل غير متقطع.

- تكامل ضاغط الهواء. ال يتطلب نظام النبض ضاغط هواء (بسعة 60 لتر على الأقل), الذي يتصل مباشرة بوحدة النبض. بمجرد تشغيله، صمام الملف اللولبي يفتح تلقائيًا, مما يسمح للهواء المضغوط بالدخول إلى النظام وتنظيف الفلاتر بكفاءة.

هذا الطراز مثالي لتطبيقات الطحن عالية الدقة، خاصة عند التعامل مع المساحيق فائقة النعومة والمواد ذات توليد الغبار العالي.

خاتمة

بالنسبة للعملاء الذين يحتاجون إلى طحن على نطاق أصغر، نقدم أيضًا آلات طحن مسحوق مدمجة توفر طحنًا فعالًا بتصميم موفر للمساحة.

بالإضافة إلى ذلك، من أجل خلط متجانس للمواد البودرة، يمكن دمج آلة خلط البودرة بسلاسة مع كسارة الحبوب، مما يجعلها الحل المثالي لخطوط معالجة البودرة الكاملة. اتصل بنا للعثور على أفضل آلة تناسب احتياجاتك!