春巻き機 | 春巻き製造機

| モデル | TZ-3620 |

| サイズ(mm) | 1800*660*890 |

| 重量 | 260kg |

| 熱ローラーの直径 | 400*280mm |

| 電力 | 6kw |

| カッティングパワー | 1kw |

| 容量 | 800-1000個/h |

| シートの最大サイズ(mm) | ロールのみ: 250 |

| シートの厚さ | 0.3-1.2mm |

今すぐプロジェクトマネージャーに技術的詳細を尋ねることができます

春巻き機は、春巻きの皮、フランスのパンケーキ、卵ケーキ、北京ダックのパンケーキなど、さまざまな種類のシートパスタを生産できます。これは、食品工場、食堂、屋台、レストランで広く使用されており、大規模生産における一貫性と品質を保証します。

厚さの調整オプションは0.3mmから1.2mmまであり、春巻き機は特定の生産ニーズに合わせてカスタマイズ可能で、事業の拡大と収益性を追求する企業にとって理想的な選択肢です。

あなたがヨーロッパ、アメリカ、アジアにいるかどうかにかかわらず、この機械は春巻きやその他の人気のあるシートパスタ製品の増大する需要に応えるのに役立ちます。

春巻きとは何ですか?

春巻きは、中国にルーツを持つ人気の料理で、その多様性と広い魅力で知られています。伝統的には、さまざまな風味豊かな具材を詰めた薄くてパリッとした皮で構成されていますが、「春巻き」という概念は、さまざまな国や文化で進化し、多くのユニークな形を取っています。

クラシックな春巻きの皮に加えて、卵ケーキ、ローストダックケーキ、プレッツェル、ひっくり返しパン、メラレウカケーキ、インジェラ、さらには地域によってはコーンタコスなどのバリエーションに出会うことができます。これらのバリエーションは、春巻きの概念の適応性を示しており、しばしば地元の風味や材料を取り入れています。

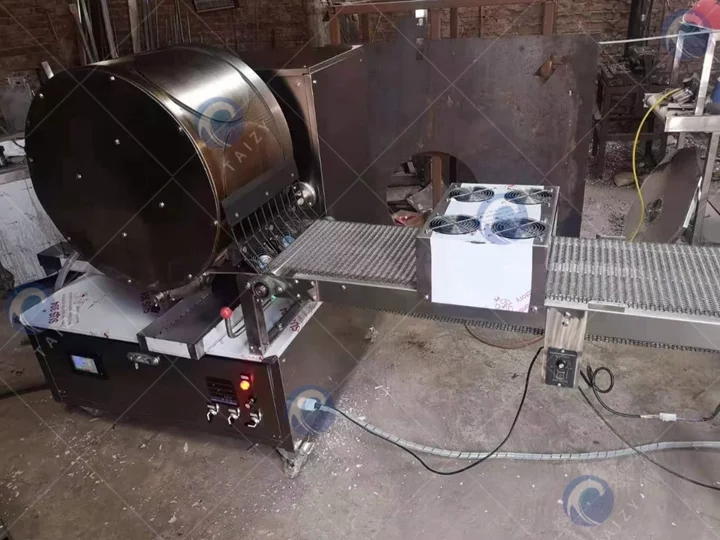

春巻き機の販売

春巻き機は、春巻き、卵ケーキ、パンケーキ、ルンピアの皮、クレープなど、さまざまなシートペストリーを生産するために設計された高効率の装置です。丸型と長方形のシートの両方を作成でき、多様な製品ニーズに応えます。

信頼できるサプライヤーとして、私たちは競争力のある価格で高品質の春巻き生地機、包装機、折りたたみ機を提供しています。詳細については、ぜひお問い合わせください!

春巻き製造機の構造

堅牢なフレームを備えた安定した運転、空気圧支援による均一な成形、そして自動制御のための電気システムを特徴としています。

正確な加熱ユニットにより一貫した焼き上げ結果を保証し、温度と時間の調整可能な設定によりさまざまな生産ニーズに対応します。

カスタマイズ可能な金型を備え、さまざまな厚さと形状の製品を製造できます。例:春巻きの皮、ダックパンケーキ、卵ケーキ。

春巻き製造機はどのように機能しますか?

- ステップ1:混合物の準備

- 事前に計量した小麦粉と水の混合物を機械の容器に注ぎます。

- ステップ2:生地の平坦化

- 機械を起動し、油圧システムが上部金型を駆動して生地を薄く均一なシートに押しつぶします。

- ステップ3:自動停止

- 平坦化工程が完了すると、自動的に停止します。

- ステップ4:冷却プロセス

- 完成したシートは冷却エリアに移され、ファンによって迅速に冷却され、サクサクとした食感と柔らかさを実現します。

春巻き製造機の性能上の利点

- 調整可能な厚さ: 春巻きの厚さをカスタマイズ可能で 0.3–1.2 mm さまざまな製品ニーズに合わせて。

- ステンレス鋼ボディ: 完全なステンレス鋼構造により 耐久性、操作の容易さ、低メンテナンス.

- 省エネモーター: 装備されています 純銅モーター 安定した性能と長寿命のために。

- 正確な温度制御: マイクロコンピュータ制御の加熱システム 一貫した正確な温度調整を保証します。

- 柔軟なカスタマイズ: 強力なカスタマイズオプション 異なる生産能力とビジネス要件に合わせるため。

春巻き製造機のパラメータ

| モデル | TZ-3620 | TZ-5029 | TZ-8045 | TZ-12060 |

| サイズ(mm) | 1800*660*890 | 2400*800*1350 | 2800*1100*1600 | 3100*1300*1800 |

| 重量 | 260kg | 520kg | 750kg | 850kg |

| 熱ローラーの直径 | 400*280mm | 500*330mm | 800*600mm | 1200*600mm |

| 電力 | 6kw | 13kw | 32kw | 48kw |

| カッティングパワー | 1kw | 1kw | 1kw | 1kw |

| 容量 | 800-1000個/h | 1500-2000pcs/h | 3000-4000pcs/h | 5000-6000pcs/h |

| シートの最大サイズ(mm) | ロールのみ:250 | ロール:350平方:300 | ロール:430平方:450 | 600 |

| シートの厚さ | 0.3-1.2mm | 0.3-1.2mm | 0.3-1.2mm | 0.3-1.2mm |

一般的な春巻き機の故障と解決策

どの機械もエラーがないわけではありません。では、もしそうなった場合、私たちは何をすべきでしょうか?ここに一般的な春巻き製造機の故障と解決策があります。

- 正常に動作しない場合。

- 解決策:電源ランプを消してください。その後、電源を入れて春巻きの皮を動かします。それでも動かない場合は、インバーターを交換してください。

- 加熱管が加熱されないか断続的に加熱される

- 解決策:漏れ制御テーブル、加熱プレート、ホットスポットが損傷しているか確認してください。もしそうであれば、適時に交換してください。

- メインエンジンは調整できません

- 解決策:スピード調整ボタンが損傷しているか確認し、スピード調整ノブの上部を強化するか、スピード調整ボタンを交換してください。

- 漏電遮断器の警告

- 解決策:加熱プレートに漏れがないか、接続ワイヤーと銅スリップリングに漏れがないか確認してください。漏れがある場合は、交換をお勧めします。

よくある質問(FAQ)

完成品の形は何ですか?

形は四角または丸、孔があるかないかです。

機械に入れる原材料は何ですか?

原材料は小麦粉のペーストで、生地ではありません。

完成品のサイズは何ですか?

四角の最大辺の長さは30cm、円の最大直径は35cm、パンケーキの厚さは一般的に0.3-1.2mmです。

加熱方法は何ですか?

電気加熱とガス加熱。

加熱温度は何ですか?

120度セルシウス。

厚さを調整するにはどうすればよいですか?

麺のペーストの比率を調整することで調整できます。ペースト:水=1:2。

どのような製品を製造できますか?

春巻きの皮の他に、ワンタンの皮、インジェラ、トルティーヤ、カラフルなパンケーキも作れます。

他の機械も提供していますか?

春巻きを作るための他の機械も提供しています。四角い春巻きを作る機械にはカッターがあります。さらに、機械には折りたたみとカウントの機能がある場合があります。

結論

春巻き機は、ビジネスに利益をもたらす優れた食品生産設備です。泰一 Machinery Co., Ltd.は、春巻き製造機の強力で信頼性の高いメーカーです。すべての私たちの機械は高性能、競争力のある価格、長寿命を誇ります。

さらに、1年間の保証サービスを提供しています。Taizy食品機械の操作やメンテナンスに関して問題が発生した場合は、当社の高度な技術を持つエンジニアが解決します。

春巻き機をオンラインで購入したい場合は、専門的な購入ガイダンスと詳細な価格リストのためにお気軽にお問い合わせください。