Automatic encrusting machine

| モデル | ST-168 |

| 容量 | 80 pieces per minute |

| サイズ | 1673*1034*1915mm |

| 電圧 | 220v, 50hz |

| 電力 | 1315w/1715w |

| 重量 | 310kg/350kg |

今すぐプロジェクトマネージャーに技術的詳細を尋ねることができます

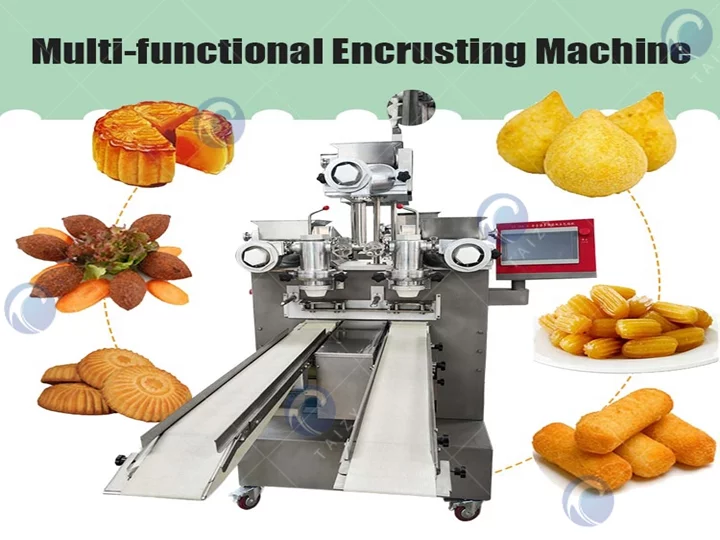

自動エンクラスト機は、詰め物のあるペストリーや詰め物食品を作るためのものです。2つのホッパーを装備しており、さまざまなフィリングを効率的に処理できるため、月餅、もち米ケーキ、その他の詰め物デリカシーを製造するのに最適です。

304ステンレス鋼で構築されており、機械は耐久性と食品安全性を確保します。製品をさまざまな形状に成形でき、ユーザーは製品のサイズと形状を簡単にカスタマイズできます。

Automatic encrusting machine for sale

私たちの販売用自動エンクラスト機は、さまざまな詰め物食品を製造するための非常に多用途なソリューションです。効率性と柔軟性を考慮して設計されており、さまざまな生産ニーズに応えるための高度な機能を提供します。

Key features of the automatic encrusting machine

- Dual-hopper design – Supports different fillings and enables stuffing-in-stuffing production.

- Two-color dough wrapping – Allows for an outer layer with two different colors, enhancing product appeal.

- Air exhaust function – Ensures better filling quality by removing excess air.

- Waste collection box – Keeps production clean and minimizes material waste.

Upgraded machine options

- Four-hopper encrusting machine – Expands production capabilities to include both stuffing-in-stuffing and two-color dough wrapping.

- Double-head encrusting machine – Produces two rows of products simultaneously, doubling efficiency.

Additional processing equipment

- Flattening machine – Customizable heated molds create precise product shapes and textures.

- Automatic tray arranging system – Ensures efficient product handling after forming.

この完全なセットアップは、正確な成形、高効率、および製品のカスタマイズの向上を可能にし、月餅、もち米ケーキ、その他の詰め物デリカシーを製造する食品メーカーに最適です。

Different types of encrusting machine

Encrusting machines come in various models to meet different production needs, from small-scale businesses to large food factories. Each type is designed with specific features to produce a variety of stuffed food products efficiently.

1. Small encrusting machine

- Suitable for making stuffed buns, stuffed pancakes, and kubba.

- Supports a maximum pancake size of 15 cm with an optional flattening device.

- Requires an air compressor for the pressing function.

2. Medium encrusting machine

- Equipped with two hoppers for dough and filling.

- Fully automatic and capable of producing various shapes.

- 付属品 3つの型 異なる製品サイズ用。

- ペアリング可能 パンケーキプレス機と カスタマイズされた形状のために。

3. Multiform encrusting machine

- 特徴 3つのホッパー ため 二色の生地 または 詰め物の詰め物製品.

- を含む 廃棄物収集システム 材料の損失を減らすために。

4. Double-head encrusting machine

- 高い生産効率を考慮して設計されており、 two rows of products simultaneously.

各タイプのエンクラスト機は、カスタマイズオプションと効率の向上を提供し、ベーカリー、食品加工工場、商業キッチンに最適です。

Automatic stuffing machine applications

Dessert filling machine structure

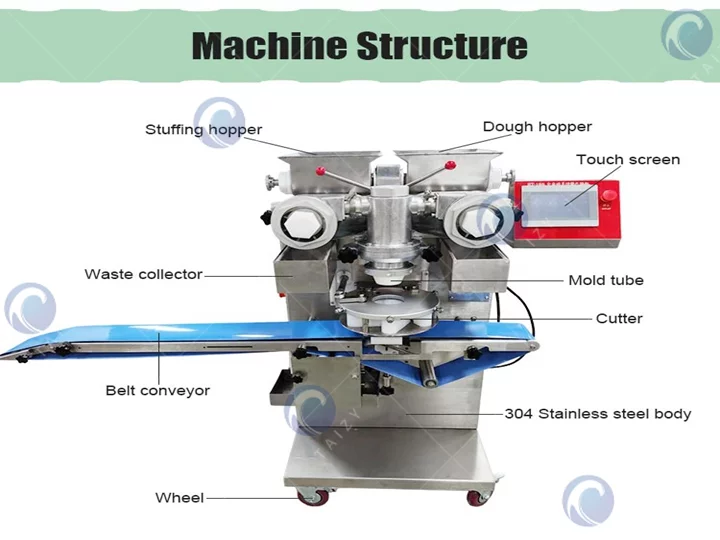

自動エンクラストマシンは、多様な生産ニーズに応えるために、堅牢で効率的な構造で設計されています。主要なコンポーネントには次のものが含まれます:

- 充填ホッパーさまざまな詰め物製品のための充填材料を保持します。

- 生地ホッパー成形とエンクラスト用の生地を保存します。

- タッチスクリーン簡単な操作と設定の正確な制御を可能にします。

- 型管製品を希望の形状とサイズに成形します。

- Cutter: Ensures accurate portioning of the products.

- Belt conveyor: Transports the finished products smoothly for further processing or packaging.

- Waste collector: Collects excess materials to maintain a clean production process.

- 304 stainless steel body: Provides durability, corrosion resistance, and food safety.

- Wheels: Facilitate easy mobility for flexible use in different production areas.

This well-engineered structure ensures high efficiency, precision, and hygiene, making it a reliable choice for food production businesses.

Automatic encrusting machine details

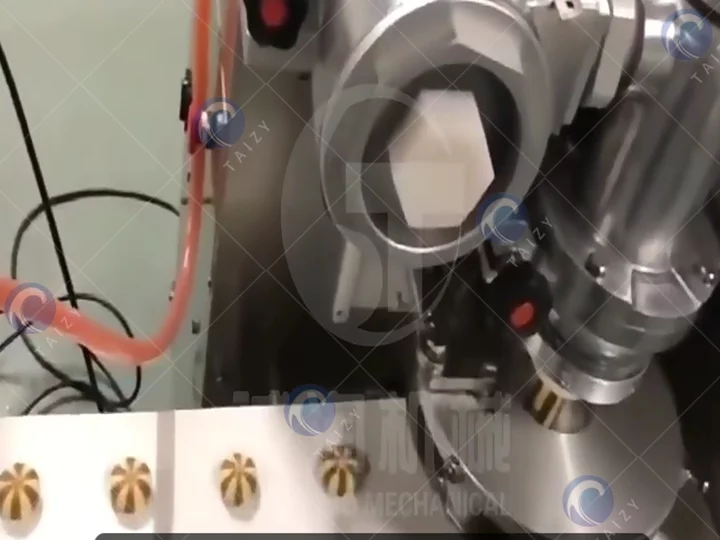

- Customizable product shapes

- Supports high-precision automatic filling and molding, ensuring consistent quality and uniformity for every product.

- Custom food shape cutter

- Prevents food from sticking, offers precise cutting, and ensures no harm to the food, maintaining product integrity.

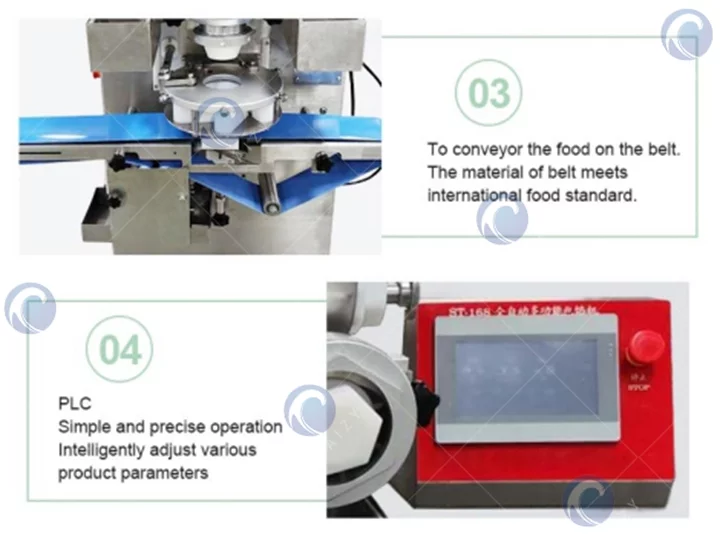

- Food-grade conveyor belt

- Made with materials that meet international food safety standards, ensuring safe and hygienic food transfer.

- PLC control system

- Features an easy-to-operate interface with intelligent adjustment of various product parameters, enhancing production efficiency.

Stuffing machine parameters

| モデル | ST-168 |

| 容量 | 80 pieces per minute |

| 重量 | 310kg/350kg |

| サイズ | 1673*1034*1915mm |

| 電力 | 1315w/1715w |

| 電圧 | 220v, 50hz |

結論

月餅、クッバ、詰め物入りバン、または二色ペストリーを作る場合、この機械は一貫した品質、高出力、精密成形を保証します。304ステンレス鋼製の構造は耐久性と食品安全を保証します。

信頼性が高く、完全に自動化されたエンカースティングソリューションをお探しなら、この機械は生産を合理化し、製品の多様性を高めるのに最適な選択肢です。

他のさまざまな食品加工機械も提供していますので、お問い合わせください!