鶏の足加工プラントはどのように機能しますか?

鶏の足加工プラントは、精密さと調整の驚異であり、生の鶏の足を一連の精巧に設計されたステップを通じて、洗練された調理可能な製品に変換します。ここでは、鶏の足加工プラントの運用ワークフローを探ります:

1. 到着と検査:

プロセスは、生の鶏の足が加工施設に到着することから始まります。最初の検査では、品質基準への適合を確認し、欠陥品や基準未満のアイテムを迅速に取り除いて、最終製品の全体的な品質を維持します。

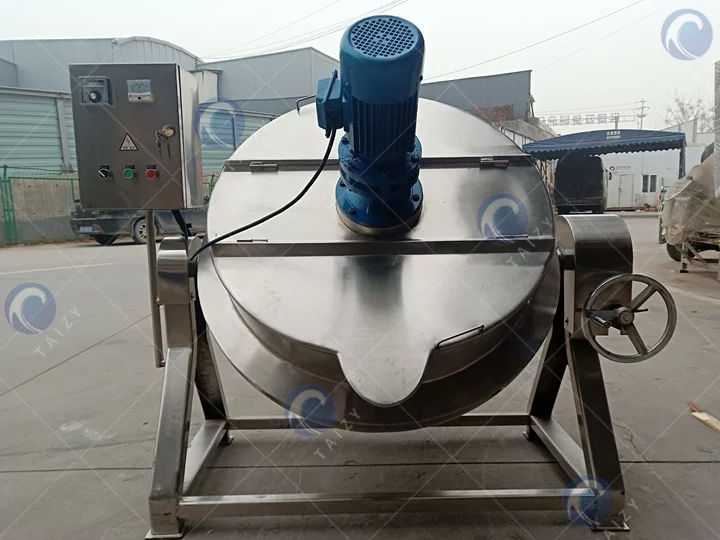

2. 湯通し:

加工ラインの最初の重要なステップは湯通しです。鶏の足は、短時間の高温蒸気にさらされます。これにより、羽毛が効率的に取り除かれ、その後の皮むきプロセスの準備が整います。湯通し機は、通常、ステンレス鋼製のボディと蒸気加熱を備えており、この基礎的なプロセスで重要な役割を果たします。

3. 皮むき:

ブランチングの後、鶏の足は皮むき機に移動します。この自動化された機器は、外皮を剥ぎ取り、より美味しい内側の層を露出させるように設計されています。周波数変換制御により、特定の要件に応じた適応性が加わります。

4. 清掃:

衛生は最重要であり、鶏の足は入念な清掃プロセスを経ます。清掃機は、特別な機器を組み込んで、不純物や残留物を取り除きます。このステップは、鶏の足が厳しい衛生基準を満たすことを保証し、最終製品の安全性と品質に寄与します。

5. 追加処理:

最終製品の希望に応じて、鶏の足加工工場は、鶏の爪開き機や鶏の爪骨抜き機などの追加機器を統合することがあります。これらの補助装置は、ラインに多様性を加え、市場の需要に基づいてカスタマイズを可能にします。

6. カット:

カット段階では精度が重要です。カット機は、ステンレス鋼製のボディと特別な鶏の足コンベヤーチェーンを備えており、鶏の足が希望の仕様にカットされることを保証します。二つのスプリットブレードの追加により、カットプロセスの効率と精度が向上します。

7. 冷凍(オプション):

一部の加工ラインでは、冷凍機が最終ステップとして組み込まれることがあります。これにより、加工された鶏の足が急速に冷凍され、保存期間が延び、長期保存と流通に必要な製品品質が保持されます。

8. 包装:

最終的に加工された鶏の足は、入念に包装され、さまざまな市場や消費者に配布される準備が整います。包装は、製品が最終目的地に到達するまでその品質と衛生を維持することを保証します。

要約すると、鶏の足加工工場は、高度に調整されたステップを通じて、技術と自動化を活用して、生の鶏の足を高品質の調理可能な製品に変換します。各段階は、全体のプロセスの効率と品質を確保するために慎重に設計されています。